Multistage automatic particle classifying equipment for amorphous refractory

A technology of particle classification and refractory materials, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of strong sealing of the device, easy accumulation of raw materials, inconvenient cleaning, etc., and achieves difficult accumulation, scientific and reasonable structure, and discharge convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

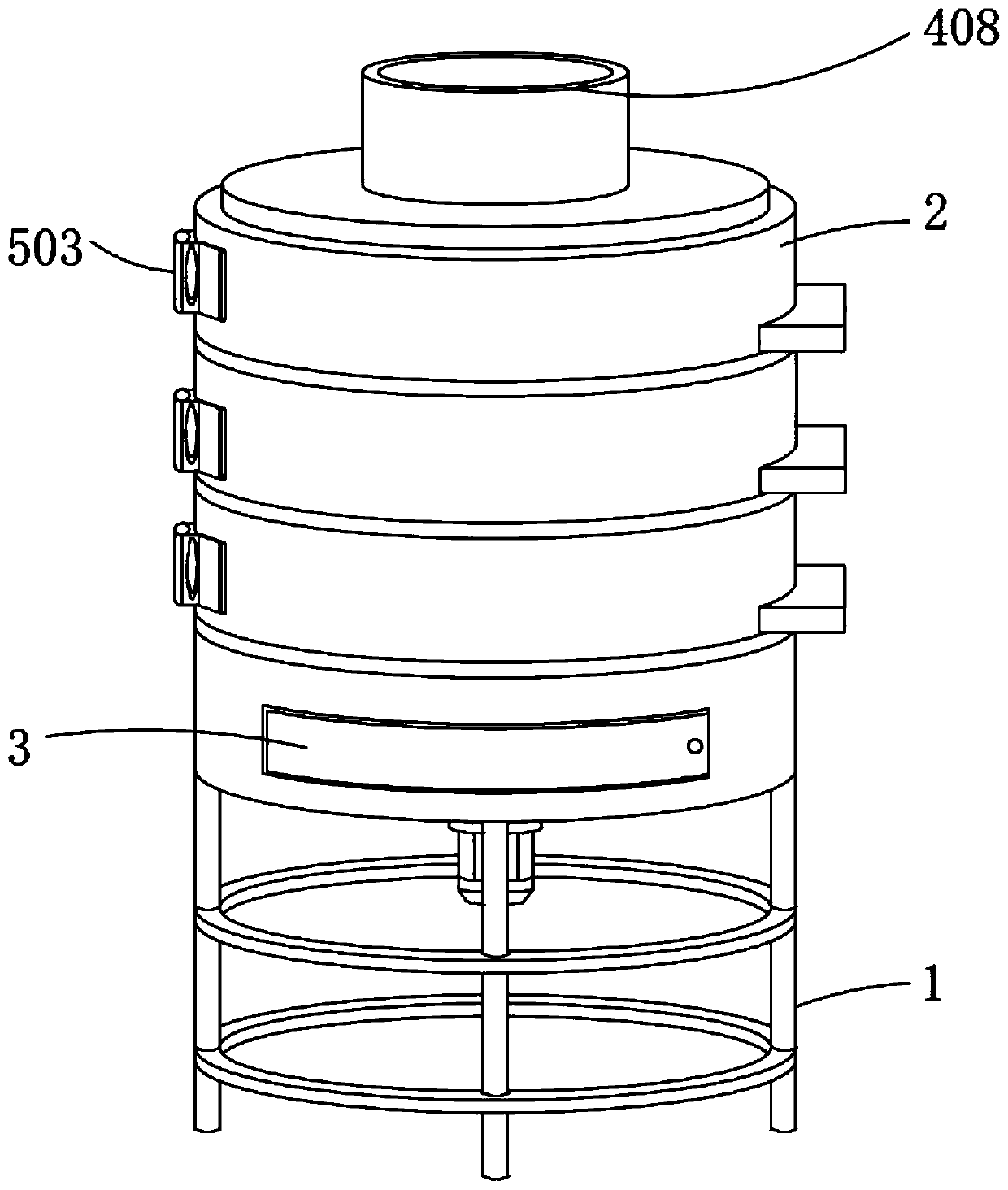

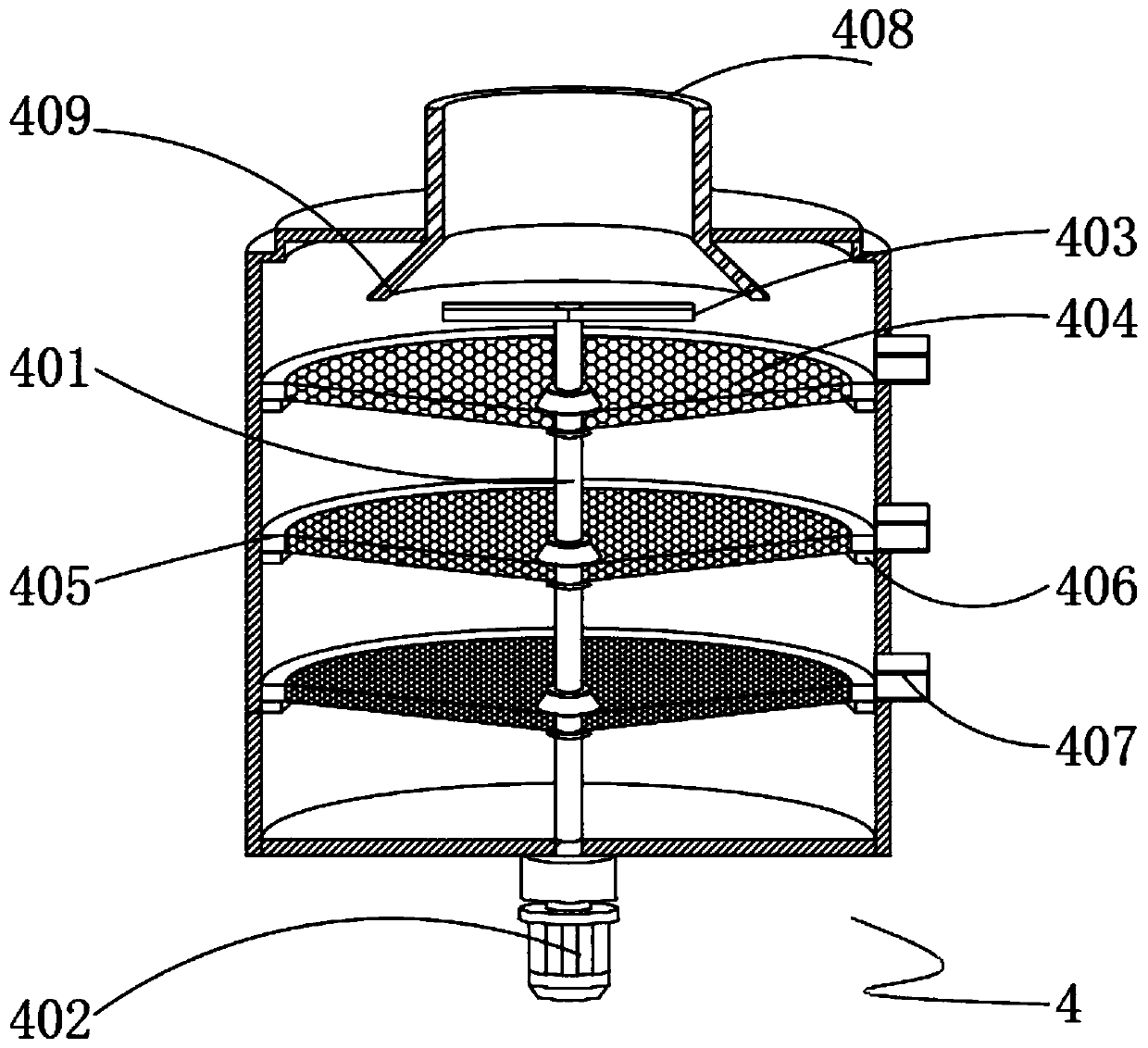

[0028] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a multi-stage automatic particle grading equipment for unshaped refractory materials, including a support frame 1, a shell 2 is welded to the top of the support frame 1, and a take-out port 3 is opened at the bottom of the front of the shell 2.

[0029] The material distribution assembly 4 is installed inside the shell 2, and the material distribution assembly 4 includes a rotating shaft 401, a motor 402, a connecting rod 403, a sieve plate 404, a positioning ring 405, a support ring 406, a discharge pipe 407, a feed pipe 408 and a retaining ring 409 .

[0030] The rotating shaft 401 runs through the middle part of the bottom end of the casing 2, and the bottom end of the rotating shaft 401 is connected with a motor 402. The top of the motor 402 is located at the bottom surface of the casing 2 and is equipped with a connecting seat through screws, which is convenient for installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com