Automatic walnut sorting device

An automatic sorting and walnut technology, applied in the mechanical field, can solve the problems of low work efficiency and unsatisfactory grading effect, and achieve the effect of high work efficiency, simple structure and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

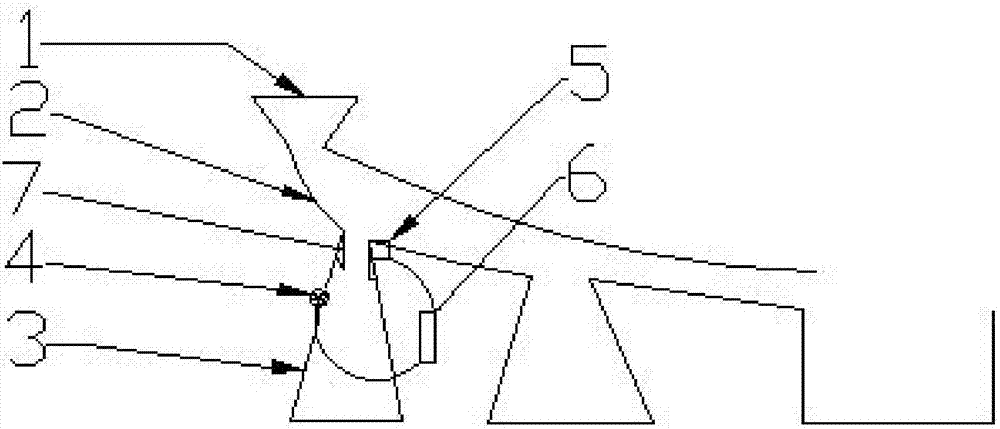

[0009] A kind of walnut automatic sorting device, such as figure 1 The feeding hopper 1, the classification channel 2, the collection frame 3, the air blowing pump 4, the pressure detection device 6, and the control module 5 are shown. The classification channel is 10°-60° from the horizontal line. There are 4 leakage holes with gradually increasing diameters, and the diameters of these four leakage holes can be adjusted. A pressure detection device is installed on the wall of the leakage holes, and an air blowing pump is installed at the lower end of the classification channel, and the blowing direction is positive. For the leakage hole, the pressure detection device and the signal device of the blowing pump are all connected with the signal device of the control module. If the diameter of the walnut is smaller than the leakage hole, the walnut will fall into the collection box, and the walnut with a diameter larger than the hole will continue to roll and fall into the hole l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com