Double-layer internal screening device

A screening device, double-layer technology, applied in the field of double-layer internal screening device, to achieve the effect of reducing infrastructure investment and the number of auxiliary equipment, compact structure, improving grinding capacity and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

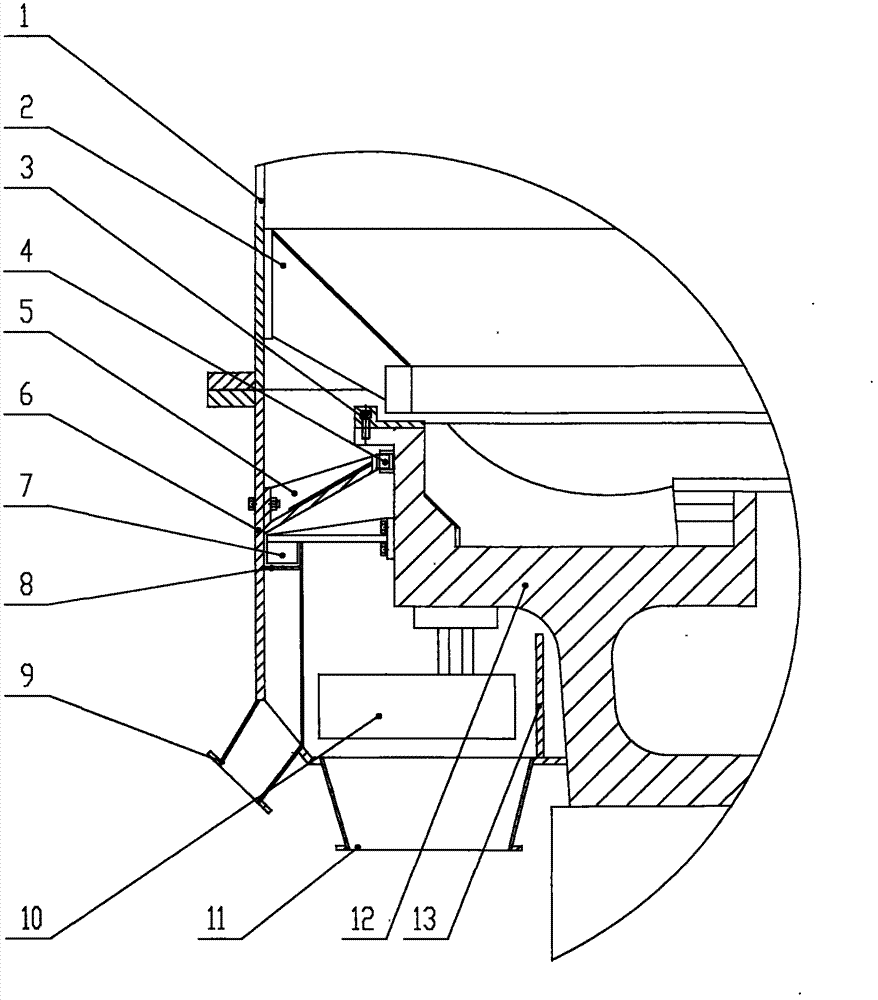

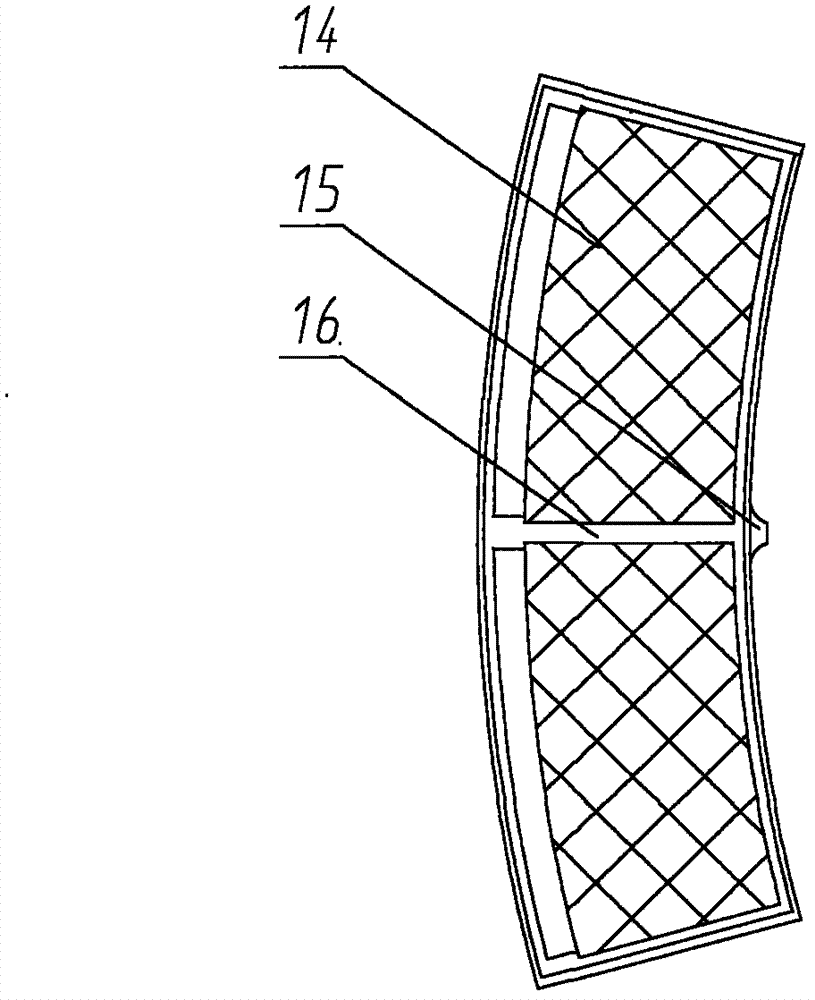

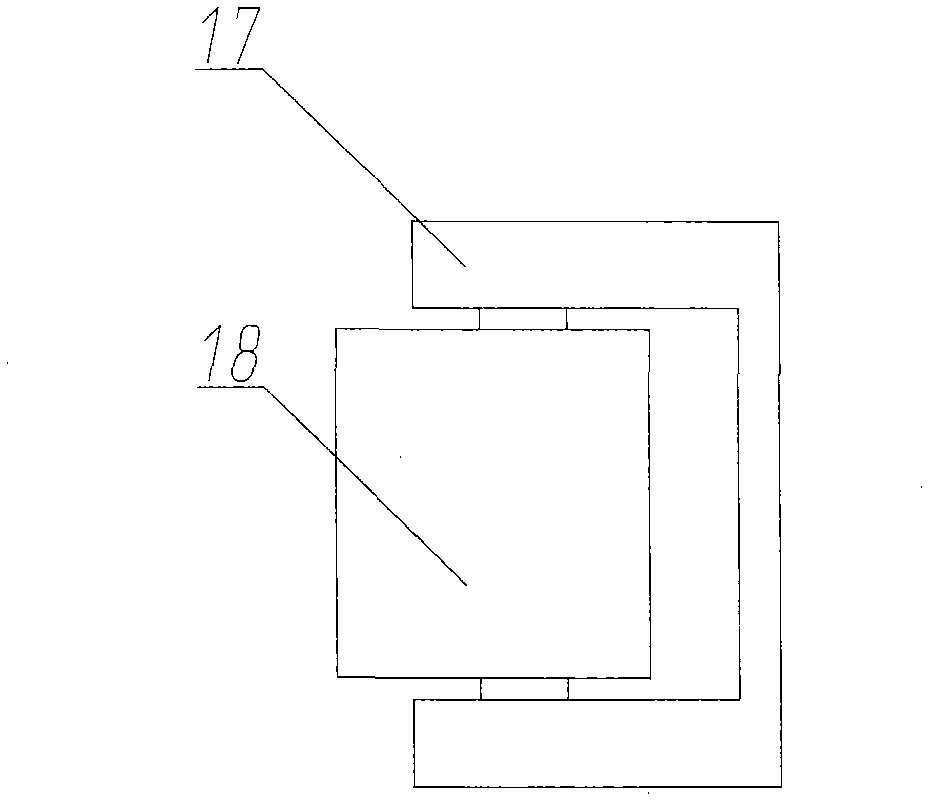

[0013] figure 1 Schematic diagram of the structure and installation of the double-layer inner screening device picture . Such as figure 1 , figure 2 , image 3 with Fig. 4, double-deck inner screening device of the present invention comprises upper screening device 2, lower screening device 5, coarse material annular groove 8, fine powder annular groove 13, scraping device one 7, scraping device two 10, coarse The material discharge port 9, the fine powder discharge port 11 and the eccentric wheel vibrator 4 are composed. It is characterized in that the upper screening sub-device 2 is composed of a screen frame 19, a screen mesh 20, a static ring 21 and a moving ring 3, the screen frame 19, the screen mesh 20, and the static ring 21 are fixed on the upper casing 1, and the moving ring 3 fixed on the grinding disc 12; the lower screening device 5 is composed of a sieve frame 16, a screen 14 and a boss 15; the fine powder annular groove 13 is fixed on the lower hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com