Inclined sieve tray type tea grader

A classifier and sieve-disc type technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of high damage rate, few fresh leaf classifications, and blurred boundaries of classifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

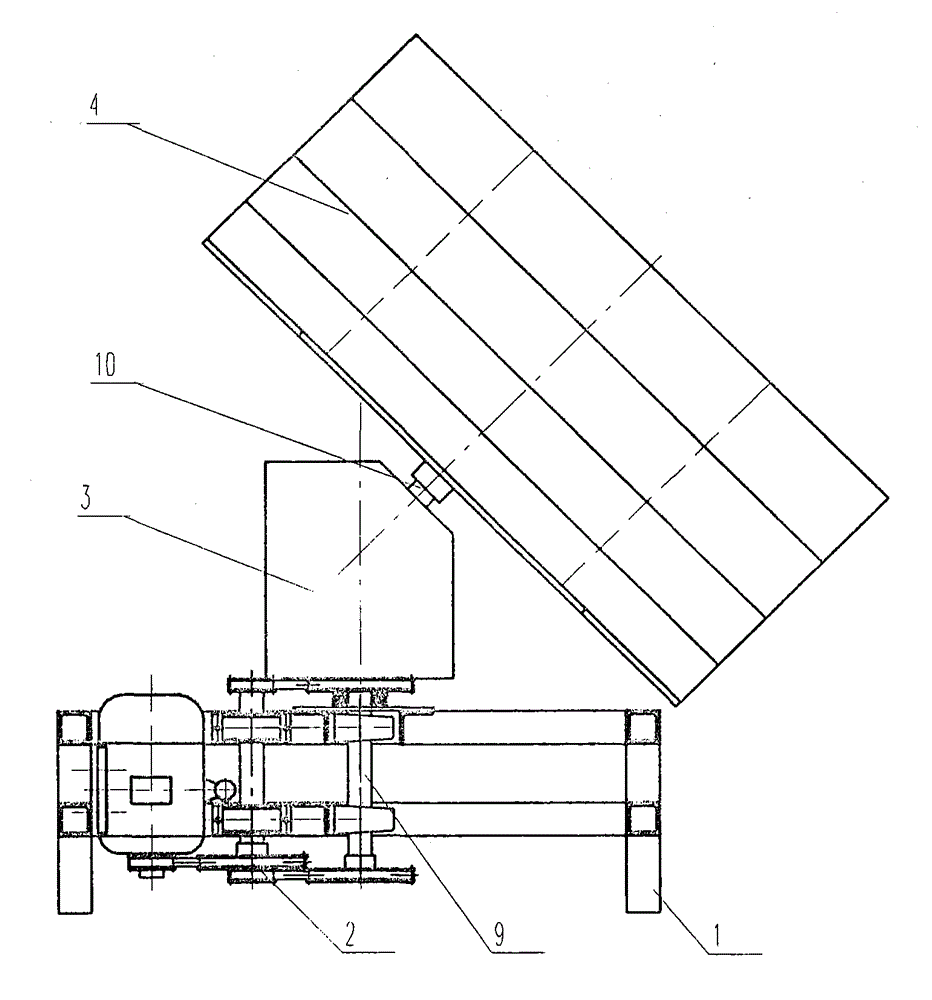

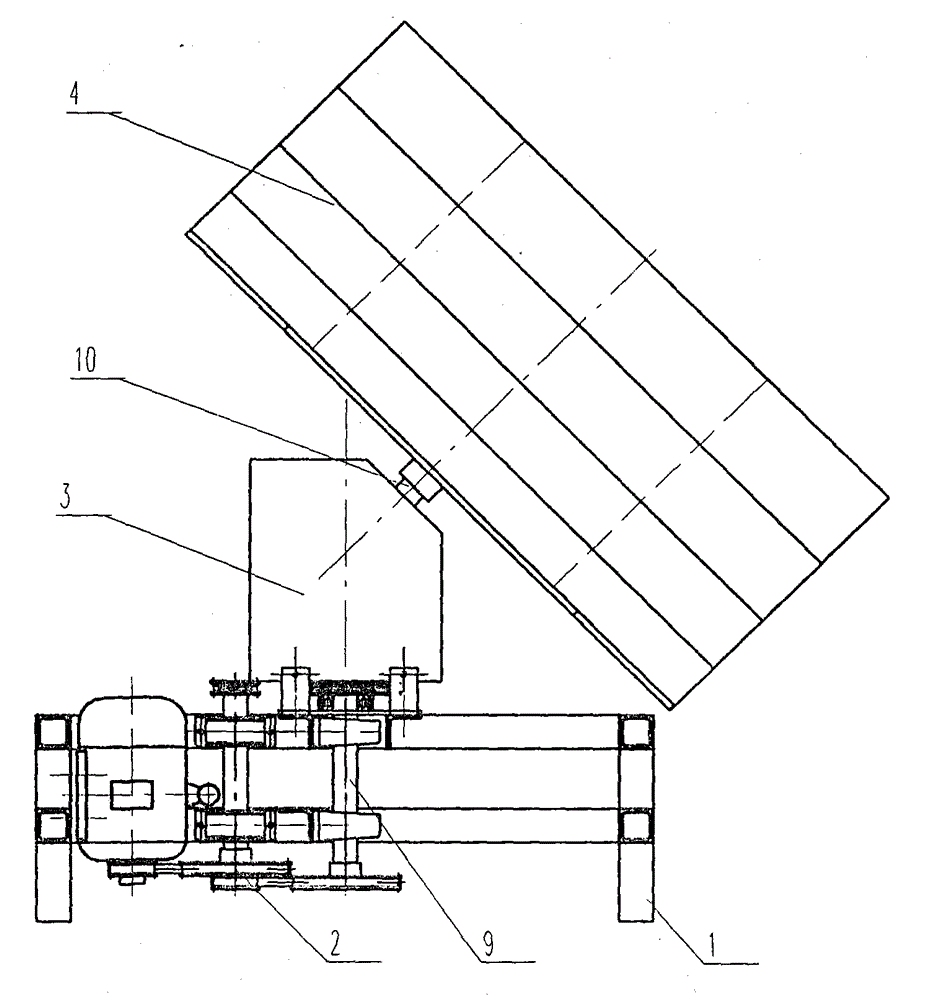

[0017] refer to figure 1 , an inclined sieve disc type tea classifier, comprising a frame 1, a transmission mechanism 2, a corner rotating device 3, and a screening device 4;

[0018] The angle rotating device 3 tilts the screening device 4 at a certain angle, and rotates the screening device 4 during operation;

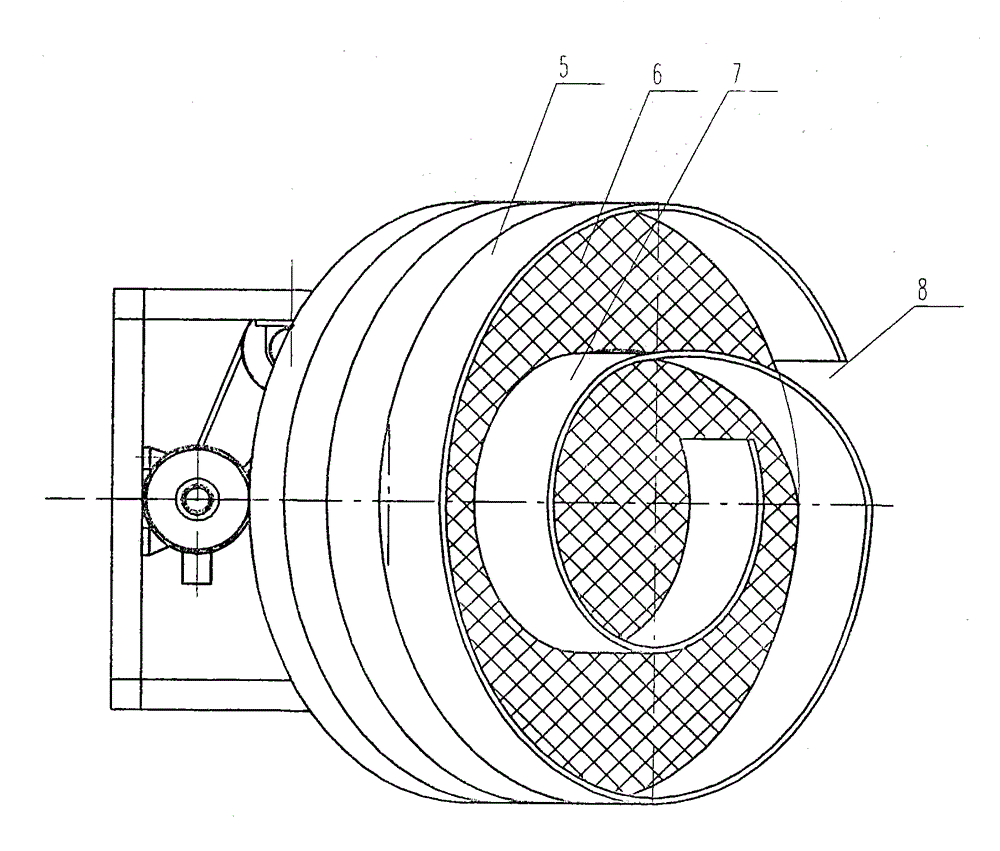

[0019] The screening device 4 is composed of four sieve trays 5 superimposed, and the sieve mesh holes decrease layer by layer from top to bottom, the sieve mesh holes of the uppermost sieve tray are the largest, and the sieve trays of the lowermost sieve tray have the smallest mesh holes;

[0020] The sieve tray 5 is made of a screen 6 and a side ring 7;

[0021] The sieve pan edge ring 7 is two concentric circles with a gap, the inner ring is connected with the outer ring at the gap, and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com