Method for preparing graphene powder

A graphene powder and graphene technology, which is applied in the field of large-scale preparation of graphene powder, can solve the problems of difficult production, uniform dispersion, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The first step: prepare graphene oxide solution. Using the improved Hummer method, take 69ml of 98% concentrated sulfuric acid, add 1.5g of natural flake graphite and 1.5g of NaNO respectively while stirring 3 , accurately control the temperature of the reaction solution at 0±0.5°C, slowly add 9gKMnO 4 Powder, stir for 1 hour, add 100ml of deionized water, raise the temperature of the reactant to 95±1°C, and react for 30 minutes. Dilute the reaction solution with deionized water and add 10ml of 30% H 2 o 2 , filtered while hot, fully washed with deionized water until there was no SO in the filtrate 4 2- . Weigh 100mg of graphite oxide into a beaker, add deionized water to make a 1000ml solution, and then ultrasonically disperse the solution for 5 minutes to obtain a stable 0.1mg / ml graphene oxide suspension solution.

[0040] Step 2: Use a general-purpose spray pyrolysis dryer or similar equipment, set the air inlet temperature to 150°C, and the liquid ejection ra...

Embodiment 2

[0043] The first step is the preparation of graphene oxide solution. Using the improved Staudenmaier method, add natural flake graphite to the mixture of 98% concentrated sulfuric acid and nitric acid, stir and add potassium nitrate, control the temperature of the reaction solution at 0-10°C, stir the reactant for 6 hours to obtain graphite oxide, filter and dry to obtain graphite oxide . Weigh 300mg of graphite oxide into a beaker, add deionized water to make a 500ml solution, add 2ml of 1M KOH solution, and then ultrasonically disperse the solution for 20 minutes to obtain a stable 0.6mg / ml graphene oxide suspension solution.

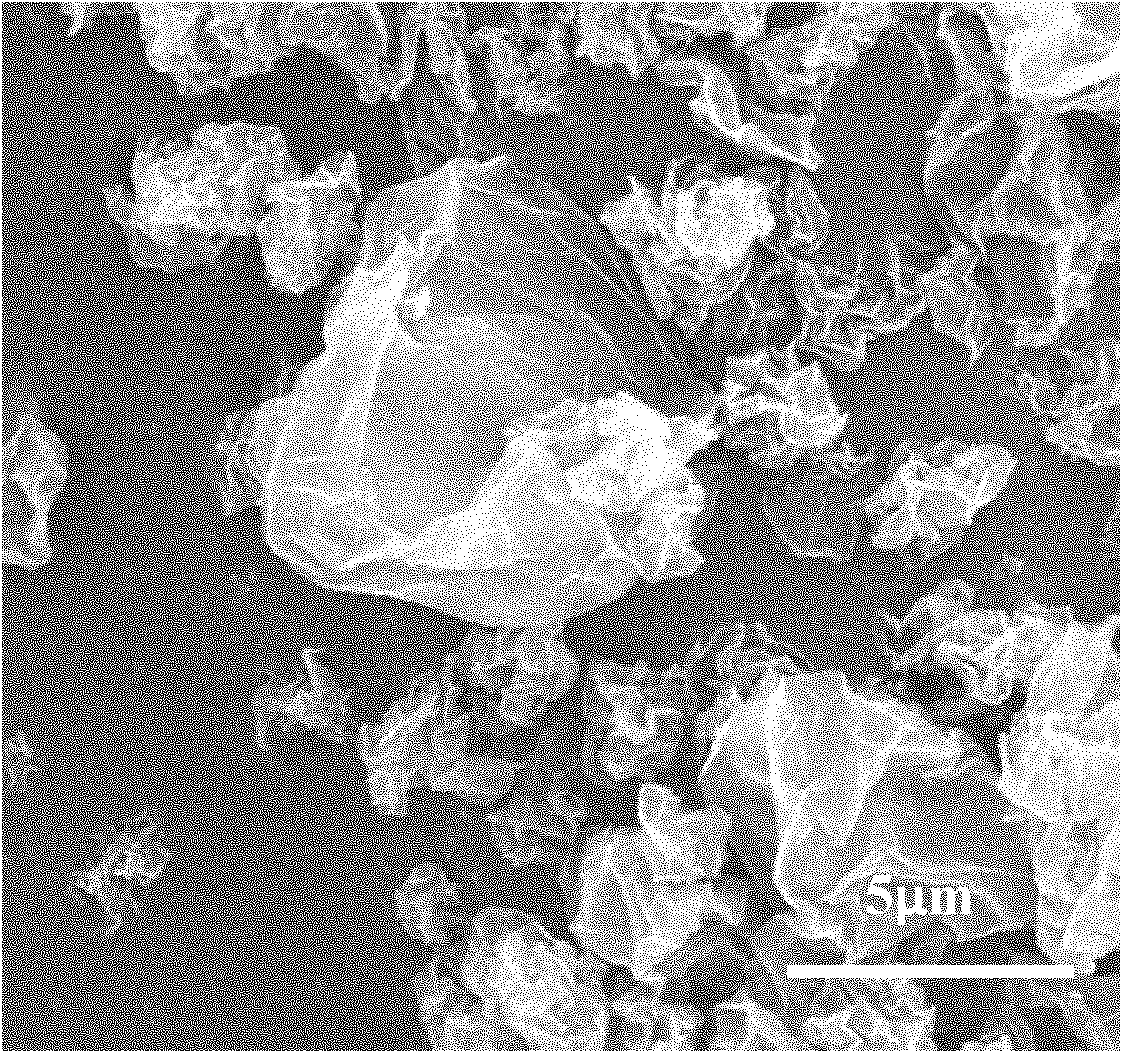

[0044] Step 2: Use a general-purpose spray dryer or similar equipment, set the temperature of the air inlet to 200°C, the spray rate of the liquid to 2000ml per hour, and the diameter of the nozzle to be 2mm. The graphene oxide powder was collected, and the field emission scanning electron microscope test proved that the graphene oxide powder obtaine...

Embodiment 3

[0047] The first step: the preparation of graphene oxide solution is the same as case 2. Weigh 1g of graphite oxide into a beaker, add deionized water to make a 500ml solution, add 10ml of 1M NaOH solution, and then ultrasonically disperse the solution for 60 minutes to obtain a stable 2mg / ml graphene oxide suspension solution.

[0048] Step 2: Use a general-purpose spray dryer or similar equipment, set the temperature of the air inlet to 300°C, and the spray rate of the liquid to be 1000ml per hour. Collect the graphene oxide powder field emission scanning electron microscope test to prove that the graphene oxide powder obtained by this preparation technology is not agglomerated, such as Figure 5 shown.

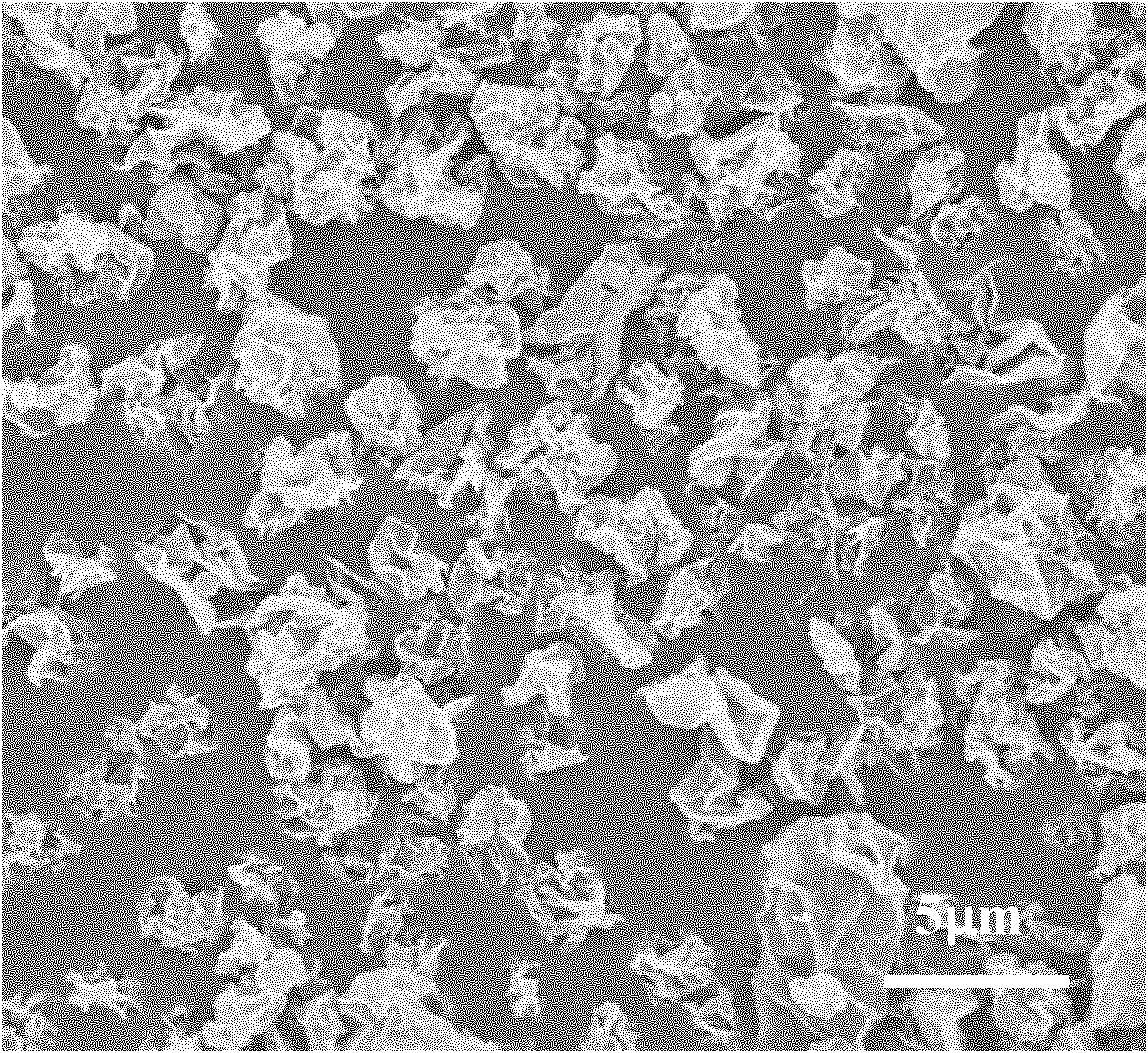

[0049] The third step: raise the graphene oxide powder to 600°C under the protection of hydrogen and keep it warm for one minute to obtain graphene powder without agglomeration. Figure 4 resemblance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com