Vibration fluidized bed drying device and drying method

A technology of vibrating fluidized bed and drying device, which is applied in the directions of drying gas arrangement, drying solid materials, and heating to dry solid materials, etc., can solve the problems of high investment in environmental protection equipment, high energy consumption in the drying process, and complex processing equipment, etc. The effect of increased dwell and drying time, small equipment size, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

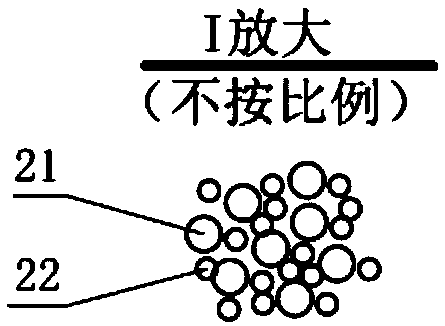

[0035] The drying device of the present invention can be applied to the drying of any solid powder and granule, wherein the selection of the inert particles is not to react with the dried powder and has a close bulk density with the dried powder, such as ceramic balls, glass balls, Stainless steel balls, etc., wherein the ceramic balls can be aluminum oxide ceramic balls, silicon carbide ceramic balls, metal powder ceramics, etc.

[0036] In order to make the present invention easy to understand, the present invention will be further described in conjunction with specific embodiments. This example takes sodium thiocyanate crystalline particles with a dry particle size of less than 0.3mm as an example, and the density of sodium thiocyanate is 1.7g / cm 3 .

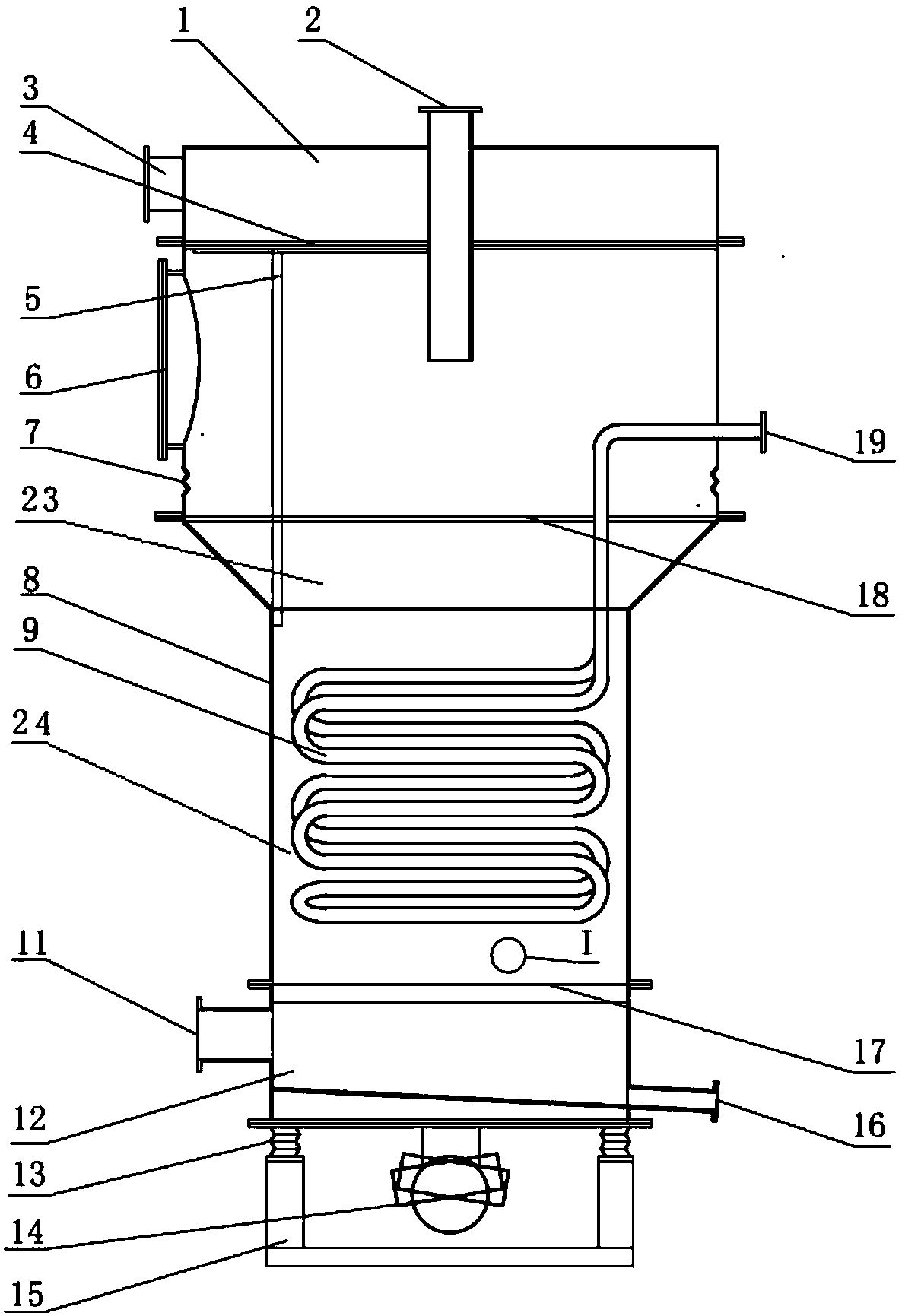

[0037] Such as figure 1 The shown vibrating fluidized bed dryer adopts fluidized heat carrier and internal heat exchanger to dry sodium thiocyanate crystal particles, including a particle settling chamber 1 set from top to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com