Cathode material of lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as loss of electrical contact of electrode materials, degradation of electrode cycle performance, and collapse of material structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

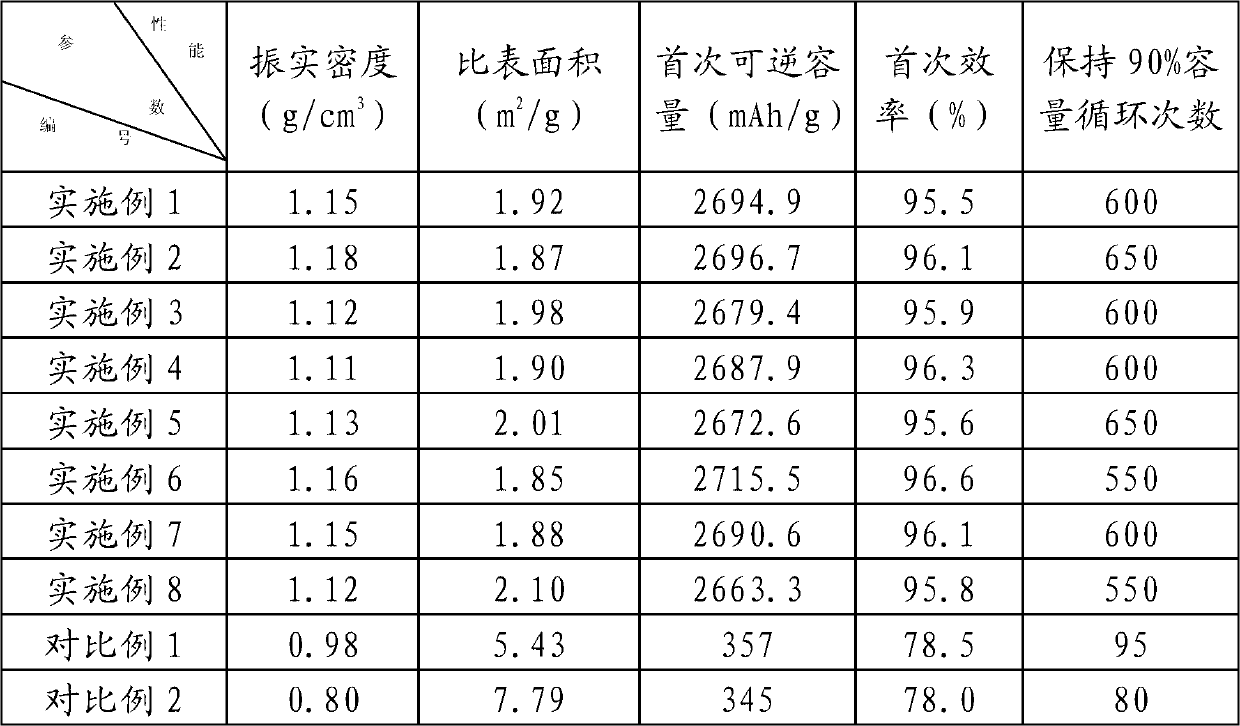

Examples

Embodiment 1

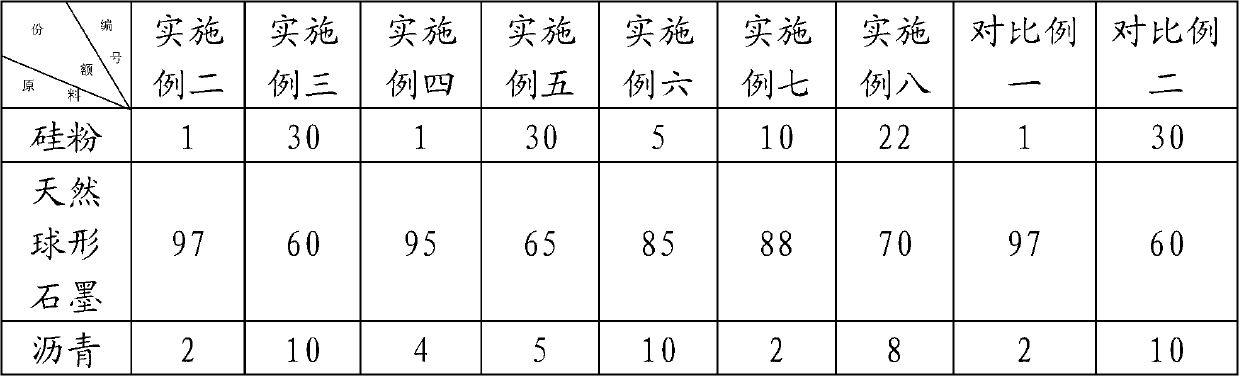

[0018] Prepare each raw material according to the specifications and mass shares listed in Table 1:

[0019] The mass proportion and specification of each raw material of table 1 embodiment one

[0020] raw material

Mass share

Specification

Silicon fume

15

Particle size range: 50-500nm

natural spherical graphite

78

Particle size range: 7-22um, fixed carbon content: ≥99.95%

7

[0021] Steps:

[0022] a) Add NMP solution of specific polymer to silicon powder, stir for 4 hours, then dry at 60-100°C;

[0023] b) Mix silicon powder and graphite by mechanical ball milling, the speed of mechanical ball milling is 1000-4000rpm, and the ball milling time is 1-10 hours; then dry under vacuum conditions, the vacuum drying time is 4-16 hours, the drying temperature 40-200°C;

[0024] c) Dissolving the coating agent in a solvent to prepare a solution of the coating agent, the dissolving temperature is 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com