Preparation method of expanded graphite flake/thermosetting resin composite material

A resin composite material and expanded graphite technology, applied in the field of resin matrix composite material preparation, can solve the problems of complex process, long cycle, release a large amount of toxic gas, etc., and achieve the effect of reducing the possibility of agglomeration and speeding up the curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Put 1g of expandable graphite into a 50 mL porcelain crucible, put it in a muffle furnace at 900°C, stay for 30s, and take it out to obtain expanded graphite.

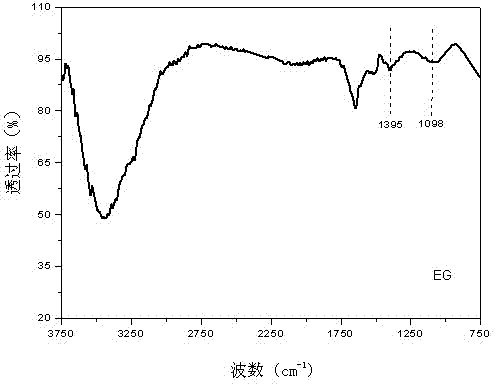

[0032] See attached figure 1 , It is the infrared spectrum of the expanded graphite provided in this example. As you can see, 1098cm -1 And 1395cm -1 There are the stretching vibration peak of C–O and the bending vibration peak of –OH, indicating the existence of hydroxyl active functional groups on the surface of expanded graphite.

[0033] 2) 10g bisphenol A epoxy resin (brand E51, epoxy value 0.51 mol / 100g, viscosity at 70°C is about 0.4Pa.s) mixed with 0.17g expanded graphite, and stirred with ultrasonic vibration at 70°C Uniform and obtain a mixed solution.

[0034] 3) Put the mixed solution in a vacuum oven at 70°C and apply a vacuum (vacuum degree of 6 Pa) for 30 minutes to obtain dispersion A.

[0035] 4) At 70°C, the dispersion A was stirred with ultrasonic vibration for 5 hours to obtain a dispersion B of ...

Embodiment 2

[0049] 1) Put 1g of expandable graphite into a 50 mL porcelain crucible, put it in a microwave oven, irradiate it with a microwave with a power of 700W and a frequency of 2.45G Hz for 10 seconds, and take it out to obtain expanded graphite.

[0050] 2) 10g of bisphenol A epoxy resin (brand E51) is mixed with 0.17g of expanded graphite, and stirred evenly with the aid of ultrasonic oscillation at 70°C to obtain a mixed solution.

[0051] 3) Put the mixed solution in a vacuum oven at 70°C and vacuum (vacuum 10 Pa) for 30 minutes to obtain dispersion A;

[0052] 4) At 70°C, the dispersion A was stirred with ultrasonic oscillation for 5 hours to obtain a dispersion B of expanded graphite flakes and epoxy resin;

[0053] 5) Add 0.5 g of curing agent (2-ethyl-4-methylimidazole) to dispersion B at 70°C, and stir the mixture with ultrasonic vibration for 5 minutes to obtain dispersion C;

[0054] 6) Pour dispersion C into the mold, and then put it in a microwave oven, use 700W power, 2.45G Hz m...

Embodiment 3

[0056] 1) Put 1g of expandable graphite into a 50 mL porcelain crucible, put it in a muffle furnace at 900°C, stay for 30 seconds, and take it out to obtain expanded graphite.

[0057] 2) At room temperature, at a molar ratio of 1:1.4, pour γ-glycidoxypropyltrimethoxysilane (brand KH-560) and deionized water into a three-necked flask and mix; gradually add an appropriate amount of hydrochloric acid, while Stir constantly to pre-hydrolyze at room temperature for about 15 minutes; condense and reflux at 55°C for 7 hours to obtain a colorless transparent liquid; put the liquid in a vacuum drying oven at 60°C and vacuum dry for 7 hours to obtain a colorless (light yellow) transparent Viscous liquid, which is hyperbranched polysiloxane (denoted as HBPSi).

[0058] 3) Add N,N'-4,4'diphenylmethane bismaleimide (BDM) and diallyl bisphenol A (DBA) to the beaker at a mass ratio of 1:0.86. Under stirring conditions, the temperature was raised to 135°C, and the reaction was stopped after 40 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com