Graphene oxide/zinc oxide antistatic polypropylene cast film

A technology of polypropylene casting and graphene, which is applied in the field of materials, can solve the problems that can only be applied in the field of insulation in industry or life, limit the use range of PP, burn or explode, etc., achieve good antistatic effect and reduce agglomeration Possibility, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

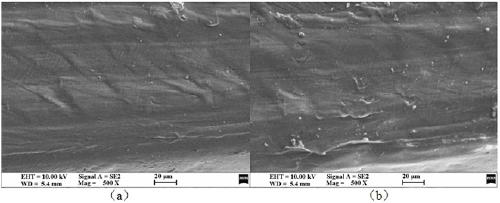

[0027] A kind of graphene oxide / zinc oxide antistatic polypropylene casting film, it is that 100 weight parts of polypropylene resin and 5 weight parts of antistatic masterbatch are dropped into in the mixer, at 60 ℃ with 300r / min high-speed stirring to make it uniform, and then through extrusion casting, cooling, edge trimming, and pressure winding, the finished product is obtained.

[0028] The preparation method of the antistatic masterbatch used is to add polypropylene resin, composite antistatic agent OA / GO-g-ZnO and EVA resin to a high-speed mixer at a mass ratio of 5:2:3, and mix at 60°C and 300r / min at a high speed Stir to make it even, then pump it into a dehumidification dryer, dry it at 50~60°C for 4-6h, and then extrude it at 190°C to obtain antistatic masterbatch.

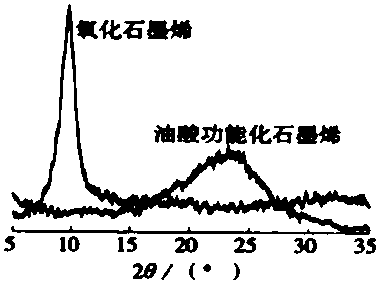

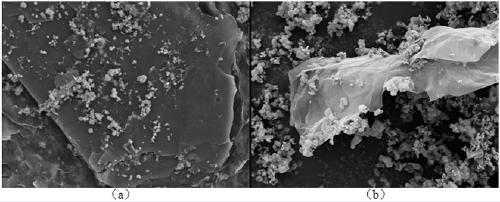

[0029] The preparation method of the composite antistatic agent OA / GO-g-ZnO is to dissolve 150g of graphene oxide and 450g of polypropylene pyrrolidone in 50mL of DMF, and in the presence of 0.5mL of t...

Embodiment 2

[0033] A graphene oxide / zinc oxide antistatic polypropylene casting film, which is to put 100 parts by weight of polypropylene resin and 10 parts by weight of antistatic masterbatch into a mixer, and stir it at a high speed of 300r / min at 60°C to make it uniform, and then through extrusion casting, cooling, edge trimming, and pressure winding, the finished product is obtained.

[0034] The preparation method of the antistatic masterbatch used is to add polypropylene resin, composite antistatic agent OA / GO-g-ZnO and EVA resin to a high-speed mixer at a mass ratio of 5:2:3, and mix at 60°C and 300r / min at a high speed Stir to make it even, then pump it into a dehumidification dryer, dry it at 50~60°C for 4-6h, and then extrude it at 190°C to obtain antistatic masterbatch.

[0035]The preparation method of the composite antistatic agent OA / GO-g-ZnO is to dissolve 150g of graphene oxide and 450g of polypropylene pyrrolidone in 50mL of DMF, and in the presence of 0.5mL of triethyla...

Embodiment 3

[0039] A graphene oxide / zinc oxide antistatic polypropylene casting film, which is to put 100 parts by weight of polypropylene resin and 15 parts by weight of antistatic masterbatch into a mixer, and stir it at a high speed of 300r / min at 60°C to make it uniform, and then through extrusion casting, cooling, edge trimming, and pressure winding, the finished product is obtained.

[0040] The preparation method of the antistatic masterbatch used is to add polypropylene resin, composite antistatic agent OA / GO-g-ZnO and EVA resin to a high-speed mixer at a mass ratio of 5:2:3, and mix at 60°C and 300r / min at a high speed Stir to make it even, then pump it into a dehumidification dryer, dry it at 50~60°C for 4-6h, and then extrude it at 190°C to obtain antistatic masterbatch.

[0041] The preparation method of the composite antistatic agent OA / GO-g-ZnO is to dissolve 150g of graphene oxide and 450g of polypropylene pyrrolidone in 50mL of DMF, and in the presence of 0.5mL of triethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com