Non-metal heat-insulation flame-retardant multifunctional plate

A multi-functional board, non-metal technology, applied in the direction of coating, layered products, wood-layered products, etc., can solve the problem of excessive dependence on metal plates, low efficiency of blocking heat radiation, non-metallic plates without flame retardant, etc. problem, to achieve excellent heat storage capacity, enhance thermal insulation effect, improve the effect of flame retardant ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

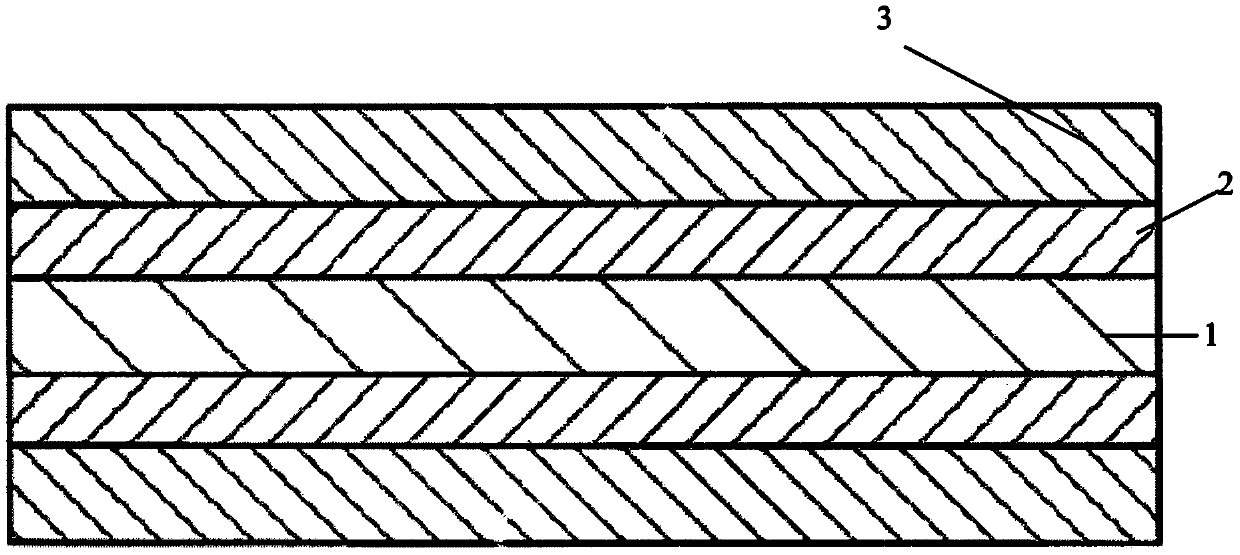

Image

Examples

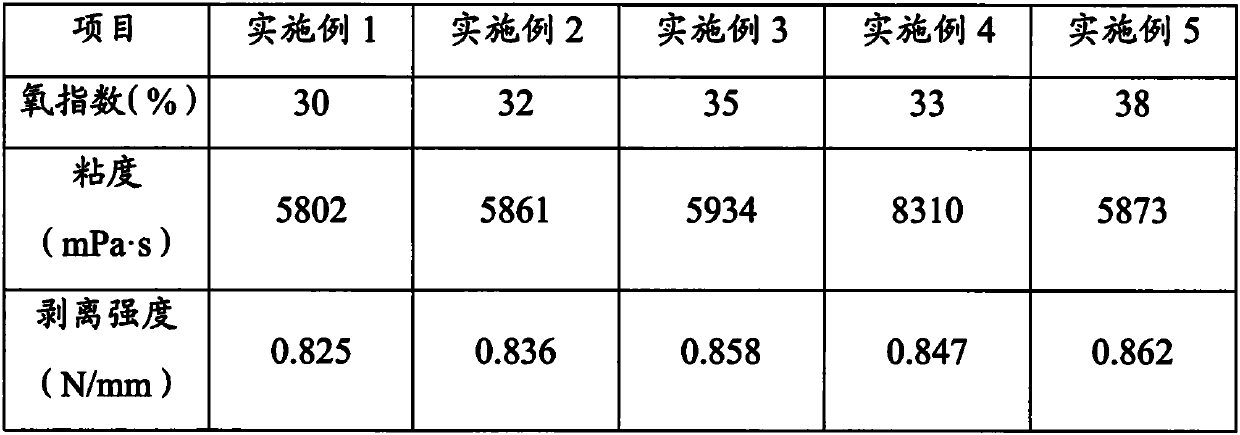

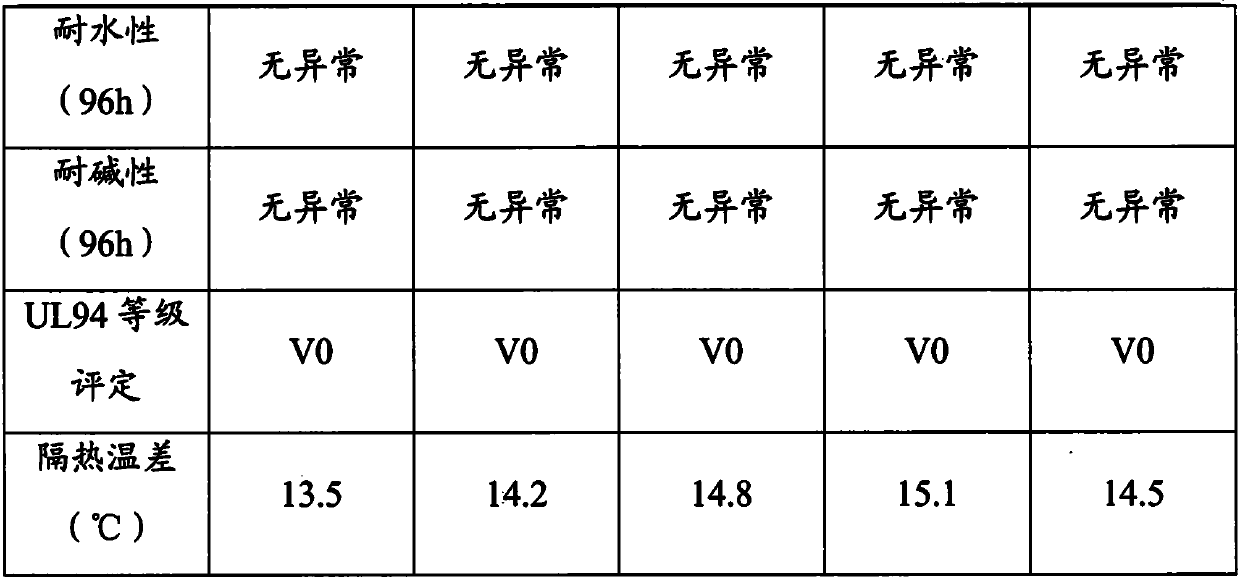

Embodiment 1

[0044]The preparation method of heat-insulating flame-retardant coating comprises the following steps:

[0045] (1) Roasting the nano-silicon carbide at a temperature of 1100° C. for 0.5 hours; then grinding the calcined nano-silicon carbide to 150 mesh to obtain modified nano-silicon carbide;

[0046] (2) Weigh 25kg of modified nano silicon carbide, 10kg of diatomaceous earth, 10kg of silica airgel, 1kg of sodium lauryl sulfate, 2kg of diisocyanate, 10kg of hexanediol butyl ether acetate, pentabromoethyl Benzene 2kg;

[0047] (3) Dissolve modified nano-silicon carbide, diatomaceous earth, silica airgel and sodium lauryl sulfate in water and add them to a water bath at 50°C, stir at 120r / min for 20min, and then Slowly add diisocyanate into the water bath and continue to stir for 20 minutes;

[0048] (4) Adjust the temperature of the water bath to 25°C, add a film-forming aid, and then dry in an oven at 140°C for 2 hours to obtain a powder;

[0049] (5) Mix the powder with a...

Embodiment 2

[0051] The preparation method of heat-insulating flame-retardant coating comprises the following steps:

[0052] (1) Roasting the nano-silicon carbide at a temperature of 800° C. for 2 hours; then grinding the roasted nano-silicon carbide to 250 mesh to obtain modified nano-silicon carbide;

[0053] (2) Take by weighing 25kg of modified nano-silicon carbide, 20kg of diatomaceous earth, 5kg of silica airgel, 5kg of sodium lauryl sulfate, 8kg of diisocyanate, 5kg of dodecyl alcohol ester, and 2kg of tributyl phosphate;

[0054] (3) Dissolve modified nano-silicon carbide, diatomaceous earth, silica airgel and sodium lauryl sulfate in water and add them to a water bath at 60°C, stir at 80r / min for 30min, and then Slowly add diisocyanate into the water bath and continue to stir for 10 minutes;

[0055] (4) Adjust the temperature of the water bath to 35°C, add a film-forming aid, and then dry in an oven at 120°C for 4 hours to obtain a powder;

[0056] (5) Mix the powder with a fl...

Embodiment 3

[0058] The preparation method of heat-insulating flame-retardant coating comprises the following steps:

[0059] (1) Calcining the nano-silicon carbide at a temperature of 900°C for 1 hour; then grinding the calcined nano-silicon carbide to 200 mesh to obtain modified nano-silicon carbide;

[0060] (2) Weigh 20kg of modified nano-silicon carbide, 15kg of diatomaceous earth, 8kg of silica airgel, 3kg of sodium lauryl sulfate, 5kg of diisocyanate, 8kg of hexanediol butyl ether acetate, and 4kg of ammonium polyphosphate ;

[0061] (3) Dissolve modified nano-silicon carbide, diatomaceous earth, silica airgel and sodium lauryl sulfate in water and add them to a water bath at 55°C, stir for 25min at a speed of 100r / min, and then Slowly add diisocyanate into the water bath and continue to stir for 20 minutes;

[0062] (4) Adjust the temperature of the water bath to 30°C, add a film-forming aid, and then dry in an oven at 140°C for 3 hours to obtain a powder;

[0063] (5) Mix the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com