Hydrotalcite coated quantum dot microsphere and preparation method thereof

A quantum dot and hydrotalcite technology, which is applied in the field of semiconductor nanomaterial preparation, can solve the problems of limiting the use range of luminescent quantum dots, the decrease of quantum dot efficiency, and the loss of luminescent performance, so as to alleviate the low luminous efficiency, expand the scope of application, reduce The effect of the likelihood of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the specific implementation manners of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by a person of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

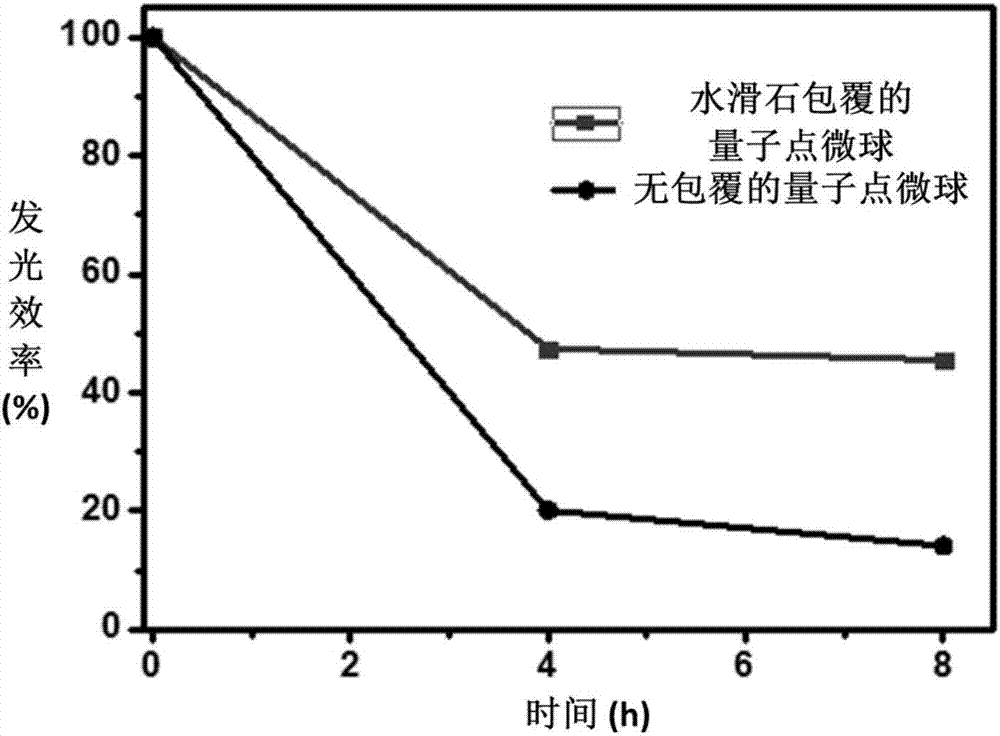

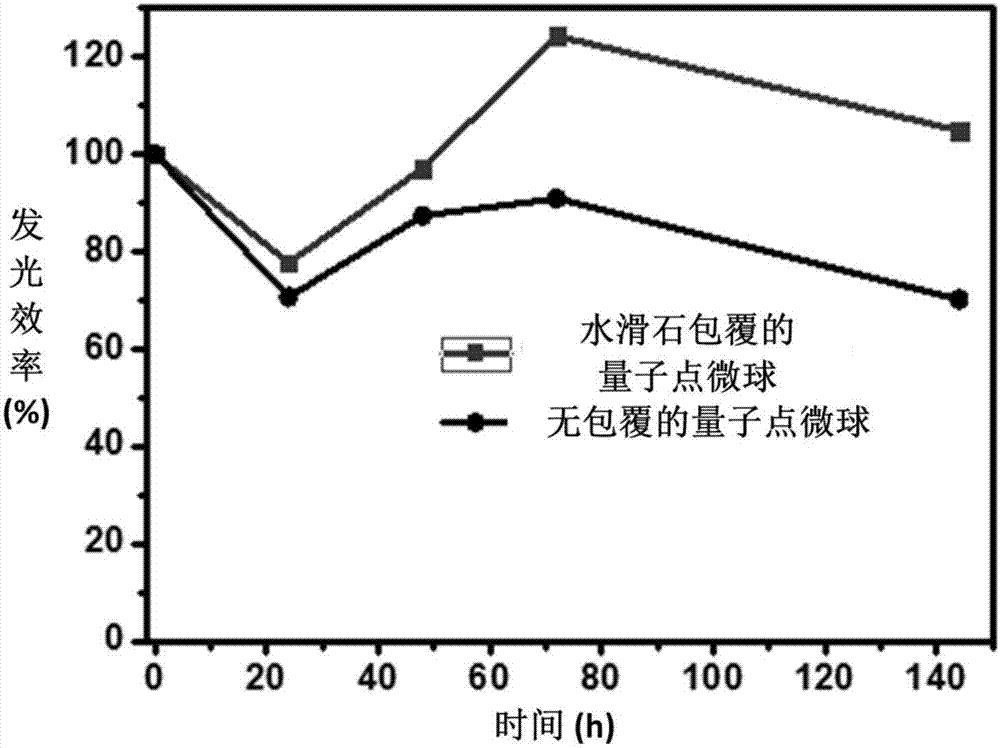

[0023] As described in the background art, due to poor barrier properties to water vapor and oxygen or instability in dielectric materials, quantum dot luminescent materials in the prior art have the problems of low luminous efficiency and poor stability. In order to improve this situation, the present invention discloses a hydrotalcite-coated quantum dot microsphere, including quantum dot microspheres and a hydrotalcite coating layer disposed on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com