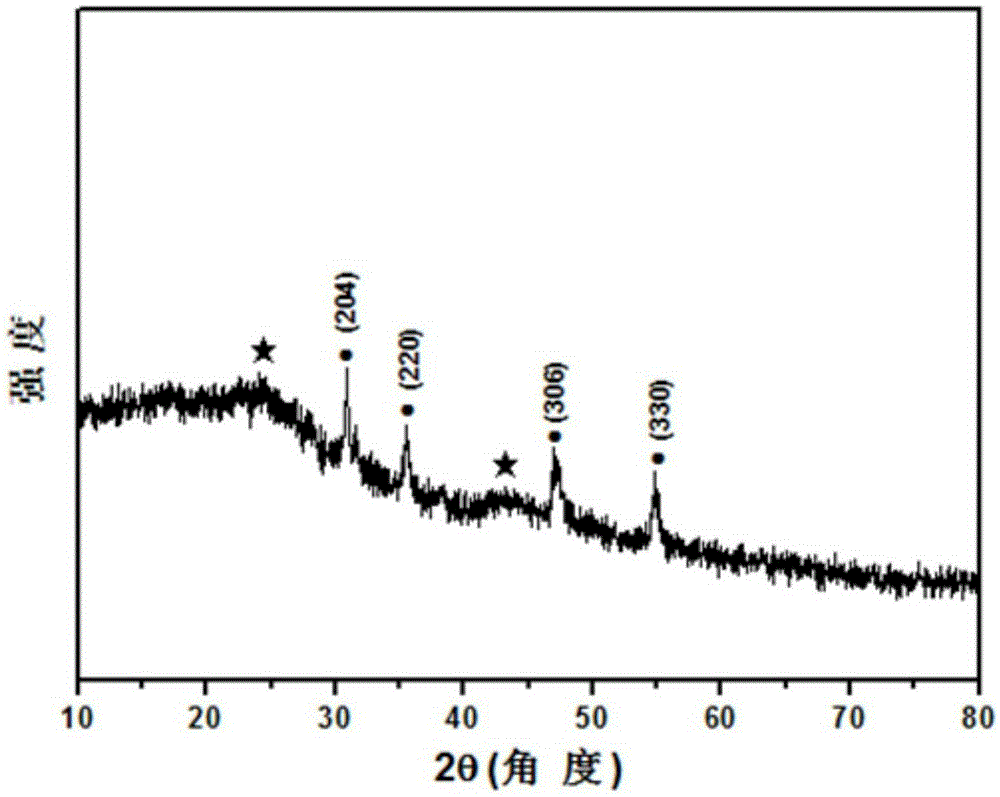

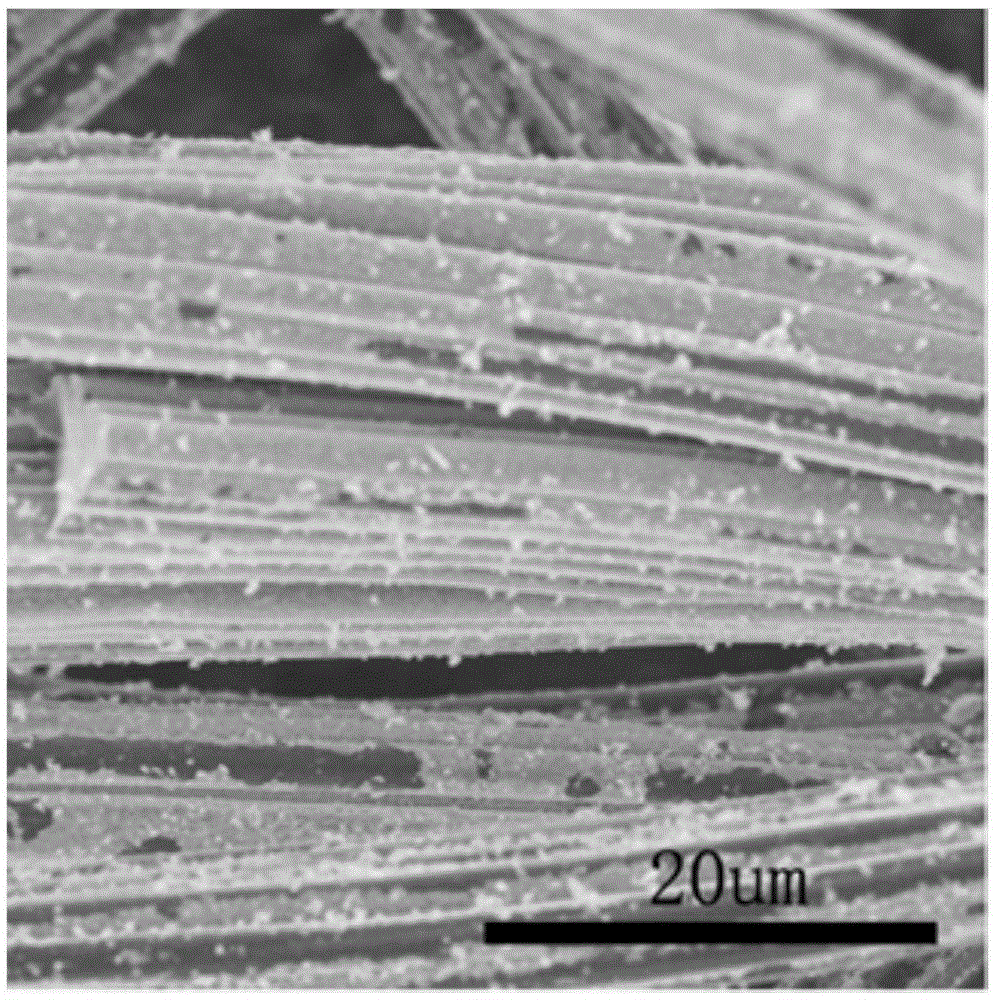

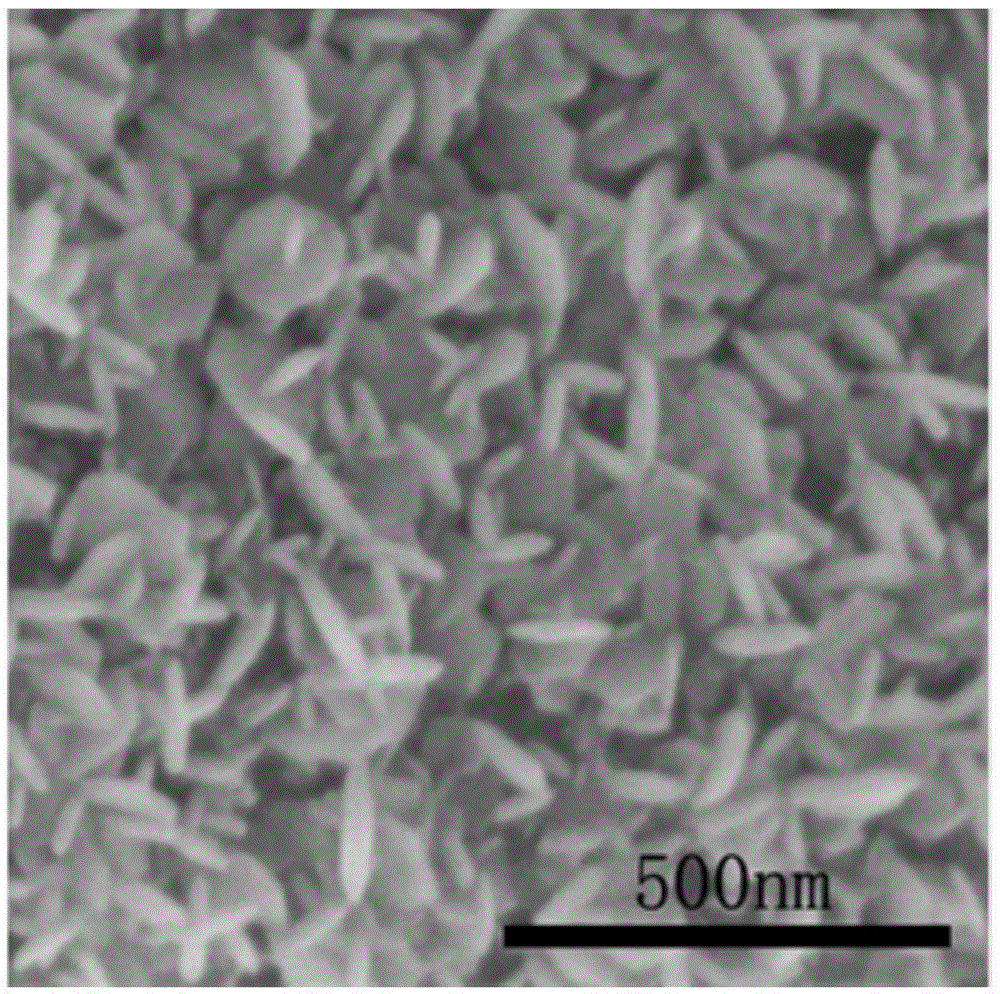

Preparation method of nickel ion doped cobalt sulfide/conductive substrate composite material

A technology of conductive substrates and composite materials, applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, can solve the problems of low rate performance, poor cycle stability, etc., achieve high rate performance, promote deposition, good Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of a kind of nickel ion-doped cobalt sulfide / conductive substrate composite material of this embodiment, specifically is carried out according to the following steps:

[0017] 1. Add the substrate into the acid solution or alkali solution, control the temperature at 25-80°C, and treat for 2-8 hours;

[0018] 2. Add cobalt salt and nickel salt to the solvent, mix evenly, then add sulfur source, stir for 0.5-3 hours to obtain a mixed solution; wherein, the mass ratio of cobalt salt to nickel salt is (15-2): 1, and the solvent The mass ratio with cobalt salt is (200~50):1, and the mass ratio between cobalt salt and sulfur source is (5~0.3):1;

[0019] 3. Add the substrate treated in step 1 to the mixed solution obtained in step 2, and then solvothermally treat it to obtain a precursor;

[0020] 4. The precursor obtained in step 3 is heat-treated in a heat-treatment atmosphere to obtain a nickel ion-doped cobalt sulfide / condu...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the substrate is carbon fiber paper, carbon fiber cloth, carbon nanotube cloth, titanium sheet or nickel foam. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: acid solution is the mixing of one or more in hydrochloric acid solution, sulfuric acid solution and nitric acid solution in step one, and the mass concentration of acid solution is 5-25%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com