Lithium sulfur battery and preparation method thereof

A technology of lithium-sulfur battery and lithium layer, applied in the field of lithium-sulfur battery and its preparation, can solve problems such as danger, consumption of lithium active material, reduction of battery capacity and Kunlun efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

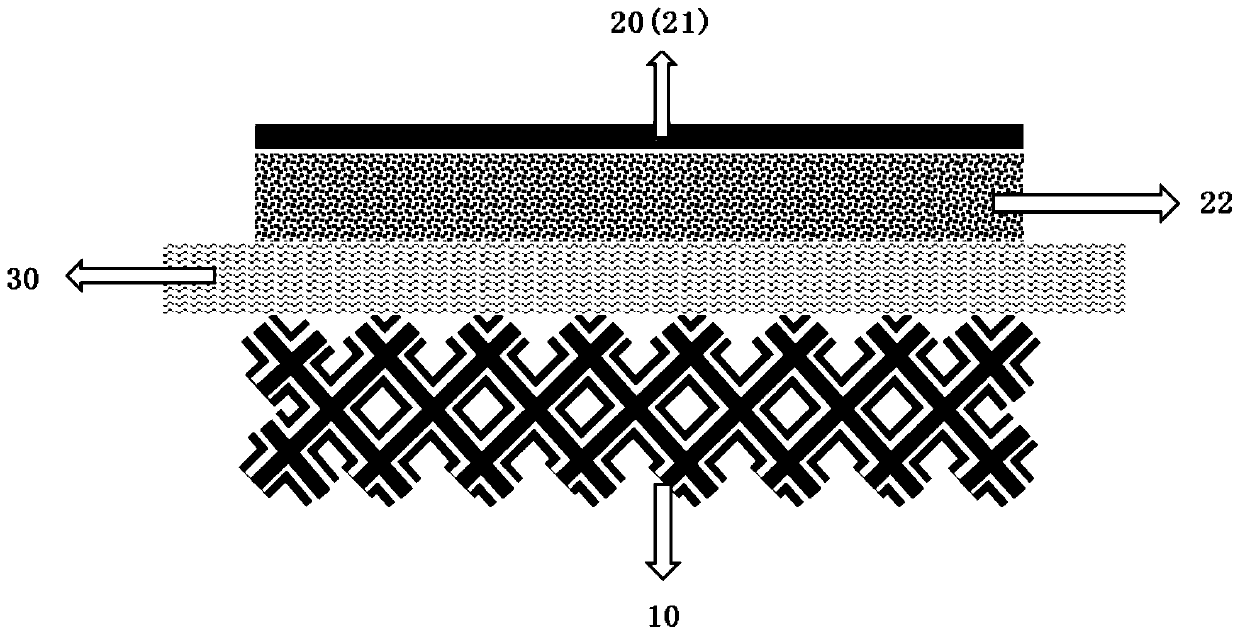

Method used

Image

Examples

preparation example Construction

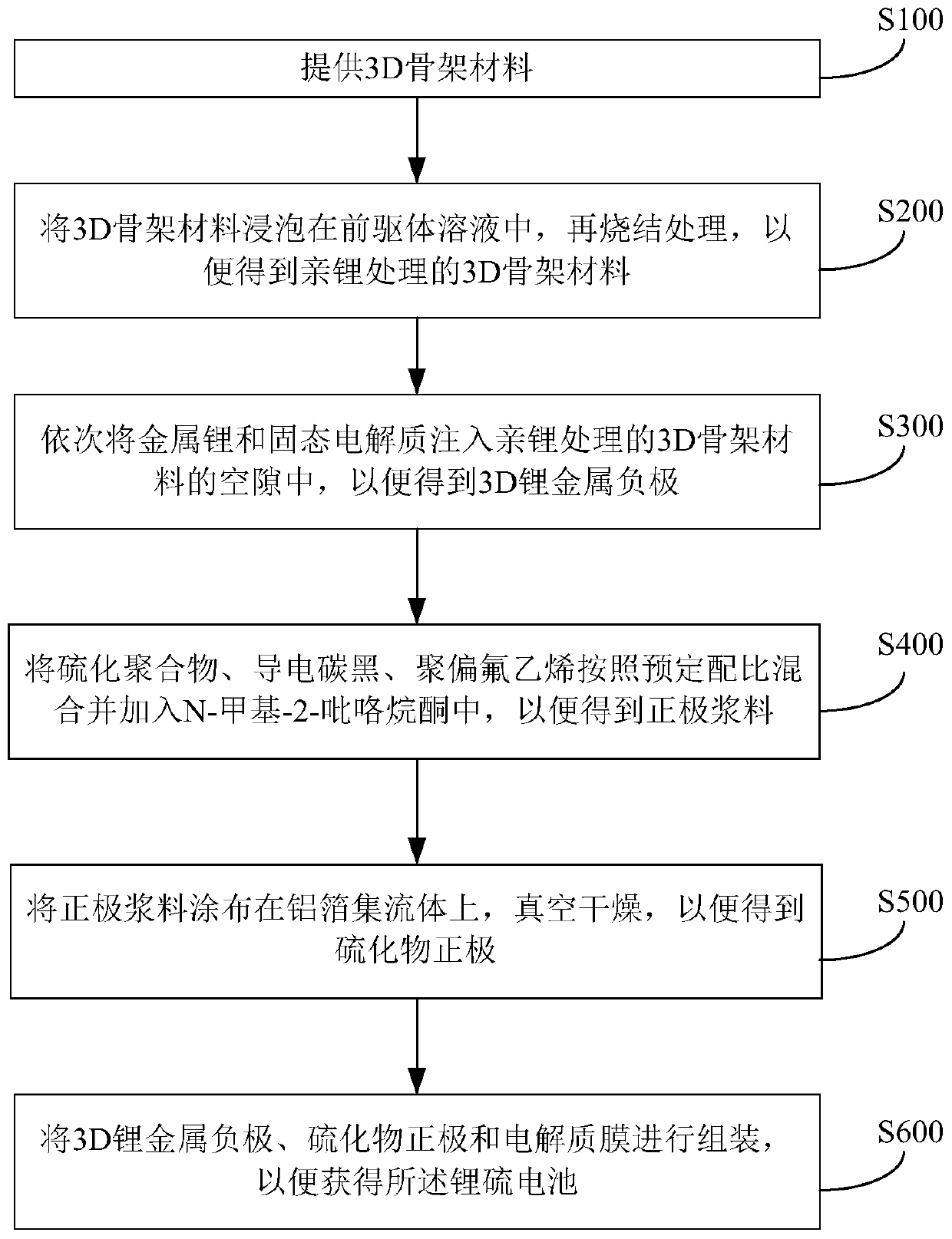

[0058] According to an embodiment of the present invention, refer to image 3 , the preparation method comprises:

[0059] S100: Provide 3D skeleton material.

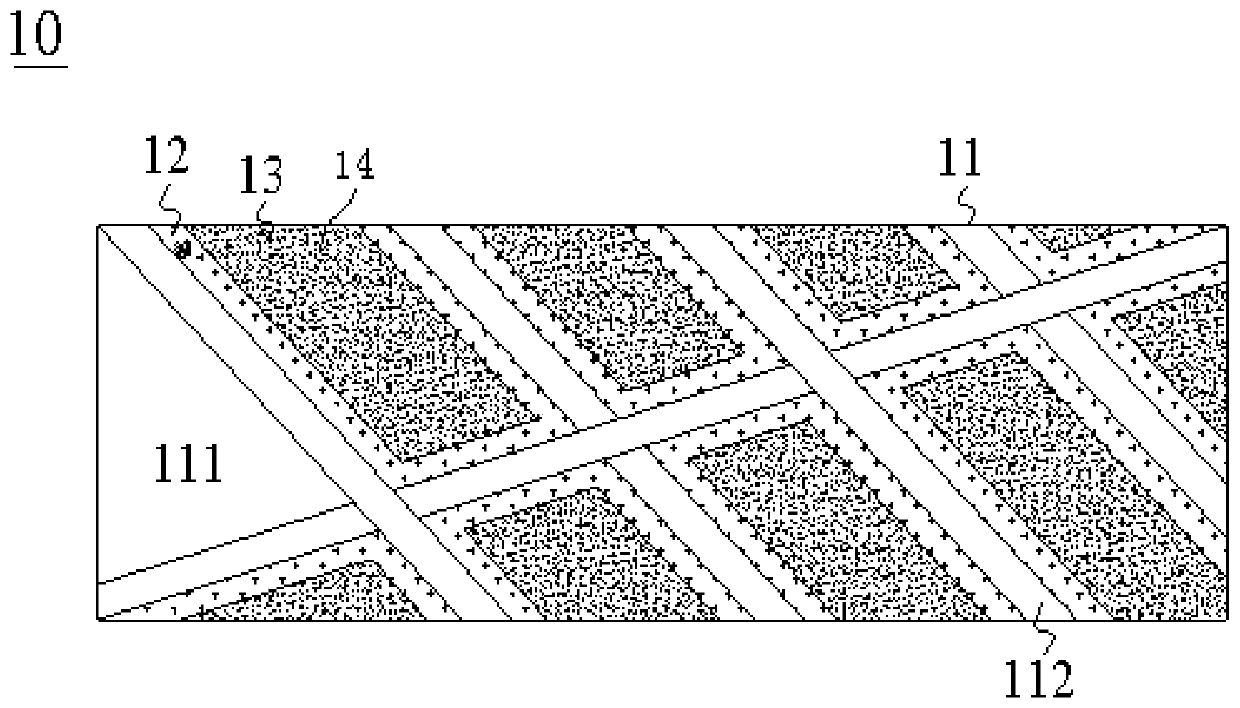

[0060] In this step, a 3D framework material 10 with a three-dimensional structure is provided as a multi-porosity support structure of the 3D lithium metal negative electrode 10 . According to some embodiments of the present invention, the above-mentioned 3D skeleton material may be carbon fiber paper, copper foam or nickel foam. According to a specific embodiment of the present invention, the above-mentioned 3D skeleton material is preferably carbon fiber paper. The method of providing the 3D framework material 10 is not particularly limited and can be purchased directly. Those skilled in the art can choose the method of providing the 3D framework material according to the specific size of the lithium metal composite electrode, and details will not be repeated here.

[0061] S200: Soak the 3D framework material in...

Embodiment

[0076] Preparation of lithium-sulfur battery, including negative electrode sheet, positive electrode sheet and solid electrolyte layer.

[0077] Preparation of 3D lithium metal negative electrode: use carbon fiber paper (the thickness of carbon fiber paper is about 100-200 μm, the diameter of carbon fiber is 5-10 μm, and there is no binder between carbon fibers) as the 3D skeleton material, and a certain amount of lithium sheet is heated to 250 ~ 400 ℃, after making it melt into liquid lithium, the carbon fiber paper is contacted with liquid metal lithium, so that the liquid lithium is automatically immersed in the pores of the carbon fiber paper. The amount of lithium in carbon fiber paper can be controlled by the amount of molten lithium flakes.

[0078] Immerse the PEO electrolyte into the 3D lithium metal negative electrode: cover the PEO electrolyte membrane on the carbon fiber paper, heat it at 70-140°C, and the PEO electrolyte membrane will be evenly immersed into the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com