Core-shell structure nanometer silicon-Mxene composite cathode material and preparation method thereof

A core-shell structure and negative electrode material technology, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of large specific surface area, increased side reactions, and limited electrochemical performance of nanoparticle materials, so as to improve electrical conductivity, improve Specific capacity and cycling stability, effect of buffer volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

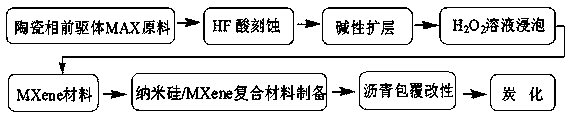

[0024] The present invention also discloses a method for preparing a core-shell structure nano-silicon-MXene composite negative electrode material, which includes the following steps:

[0025] (1) Using the ceramic phase precursor MAX as the raw material, the MXene material was obtained after etching with HCl+LiF and washing with deionized water. Specifically, the ceramic phase precursor MAX raw material is immersed in the HCl+LiF mixed etchant for stirring etching; the stirring time is 5-15min, the stirring rate is 200-800rpm, and the mass volume ratio of LiF to HCl is 1 (g): 5-15 (mL), the mass ratio of the amount of MAX phase to LiF is 1:1.05; the etched sample is transferred to a plastic centrifuge tube for centrifugation, then washed with deionized water for 3 times, centrifugally filtered, and then Shock treatment in 1mol / L KOH solution for 12h, with 30% H 2 o 2 Soak in the solution for 12 hours, wash with deionized water, and dry to obtain a two-dimensional layered MX...

Embodiment 1

[0031] A preparation method of a core-shell structure nano-silicon-MXene composite negative electrode material, comprising the following steps:

[0032] (1) Using the ceramic phase precursor MAX as the raw material, the MXene material was obtained after etching with HCl+LiF and washing with deionized water. Specifically, the ceramic phase precursor MAX raw material is immersed in the HCl+LiF mixed etchant for stirring etching; the stirring time is 15min, the stirring rate is 600rpm, and the mass volume ratio of LiF to HCl is 1 (g): 12 (mL) , the mass ratio of the amount of MAX phase to LiF was 1:1.05; the etched sample was transferred to a plastic centrifuge tube for centrifugation, then washed 3 times with deionized water, centrifugally filtered, and then in 1mol / L KOH solution Medium shock treatment for 12h, with 30% H 2 o 2 Soak in the solution for 12 hours, wash with deionized water, and dry to obtain a two-dimensional layered MXene material whose surface functional grou...

Embodiment 2

[0036] A preparation method of a core-shell structure nano-silicon-MXene composite negative electrode material, comprising the following steps:

[0037] (1) Using the ceramic phase precursor MAX as the raw material, the MXene material was obtained after etching with HCl+LiF and washing with deionized water. Specifically, the ceramic phase precursor MAX raw material is immersed in the HCl+LiF mixed etchant for stirring etching; the stirring time is 5min, the stirring rate is 200rpm, and the mass volume ratio of LiF to HCl is 1 (g): 10 (mL) , the mass ratio of the amount of MAX phase to LiF was 1:1.05; the etched sample was transferred to a plastic centrifuge tube for centrifugation, then washed 3 times with deionized water, centrifugally filtered, and then in 1mol / L KOH solution Medium shock treatment for 12h, with 30% H 2 o 2 Soak in the solution for 12 hours, wash with deionized water, and dry to obtain a two-dimensional layered MXene material whose surface functional group...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com