Lithium-sulfur battery with conductive adsorption layer, and application of conductive polymer film

A conductive polymer, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of high use cost, short cycle life, low Coulombic efficiency, etc., and achieve increased conductivity and cheap raw materials. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of conductive polymer polyaniline (PANI) adsorption layer:

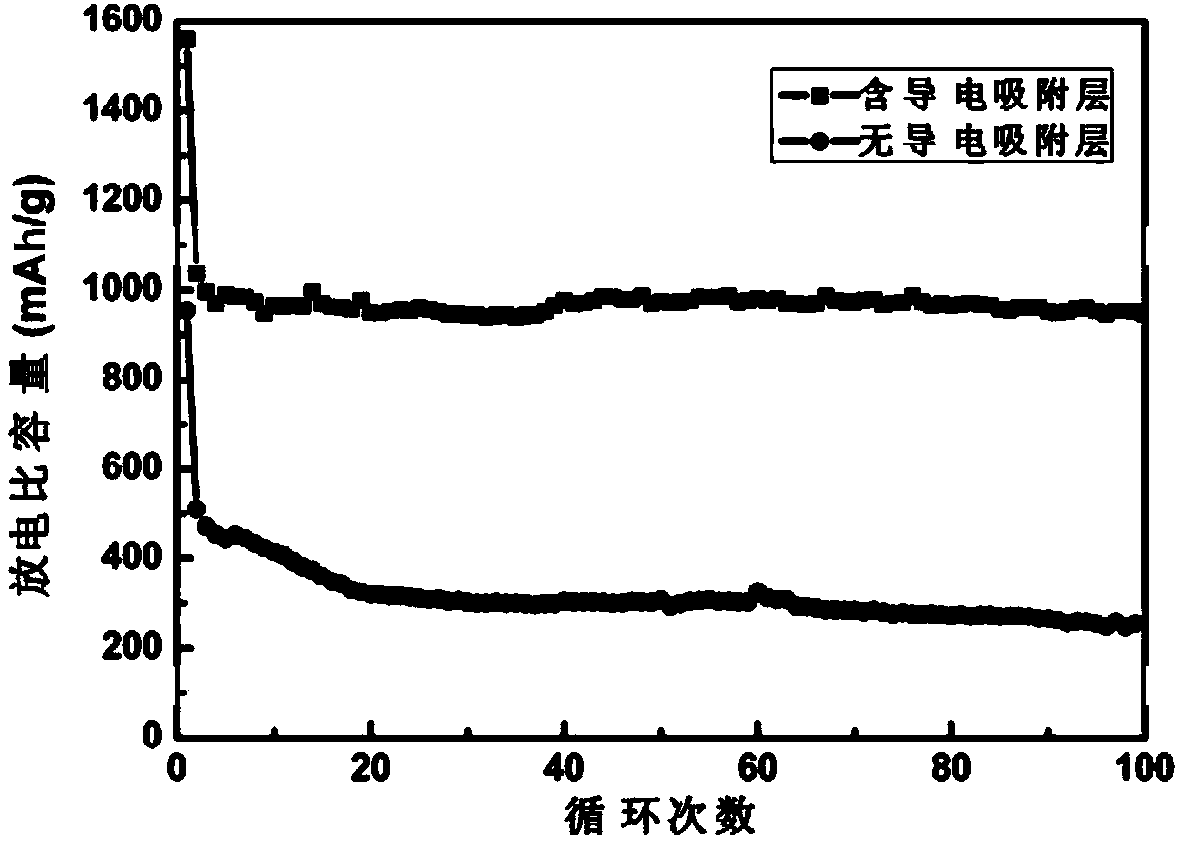

[0033] Conductive polymer PANI, conductive carbon black and polytetrafluoroethylene (PTFE) were mixed uniformly in deionized water at a mass ratio of 8:1:1, heated and stirred in a water bath for 2 hours to form a slurry with a solid content of 80%, and then The slurry was rolled repeatedly on a roller machine to form a film with a thickness of 0.5mm, dried in a vacuum oven at 70°C for 12h, and then cut into small discs with a diameter of 1.0cm to obtain a conductive polymer PANI adsorption layer. The SEM image of the conductive polymer PANI adsorption layer is as follows figure 1 shown.

[0034] Preparation of lithium-sulfur battery:

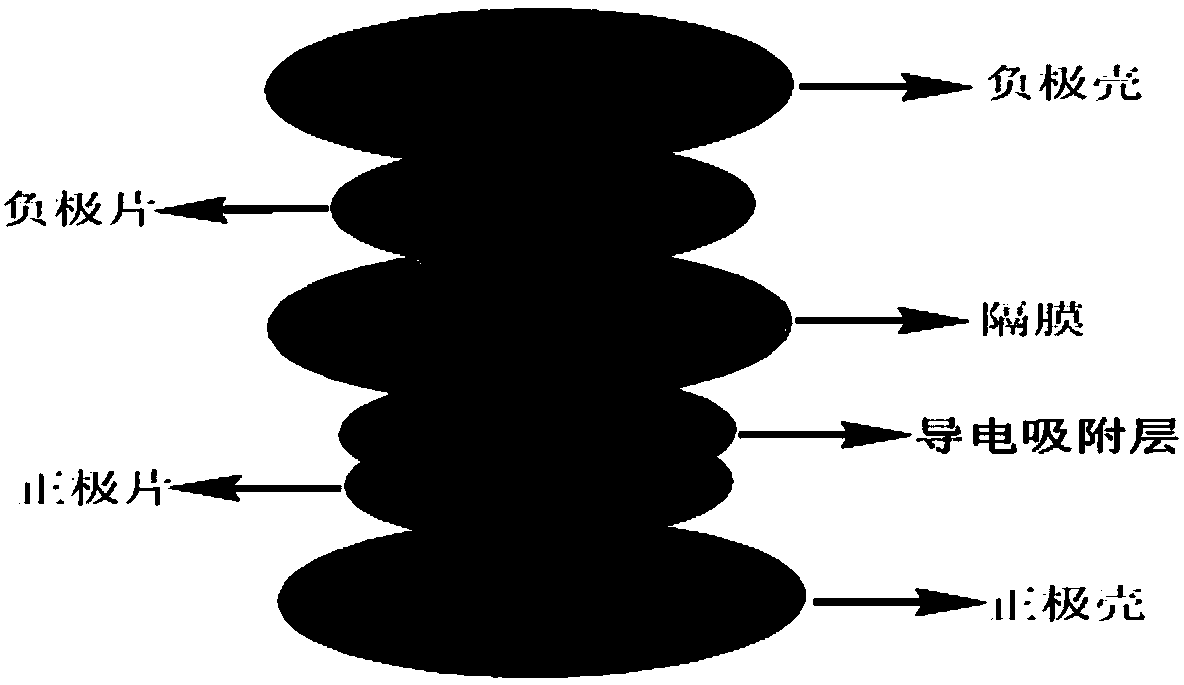

[0035]Mix elemental sulfur, conductive carbon black (SP), and polyvinylidene fluoride (PVDF) in N-methylpyrrolidone (NMP) solvent at a mass ratio of 8:1:1 to form a slurry with a solid content of 30% as The positive electrode material is coated on the aluminum fo...

Embodiment 2

[0037] Preparation of conductive polymer polypyrrole (PPy) adsorption layer:

[0038] Mix conductive polymer PPy, carbon nanotubes and PVDF in NMP at a mass ratio of 5:4:1, heat and stir in a water bath for 1 hour to form a slurry with a solid content of 50%, and then repeatedly place the slurry on a double-roll machine Rolled into a film with a thickness of 0.1mm, dried in a vacuum oven at 60°C for 20h, and then cut into small discs with a diameter of 1.2cm to obtain the conductive polymer PPy adsorption layer.

[0039] Preparation of lithium-sulfur battery:

[0040] Mix elemental sulfur, SP, and PVDF in NMP solvent at a mass ratio of 7:2:1 to form a slurry with a solid content of 30% as the positive electrode material, which is coated on the aluminum foil positive electrode current collector, and placed in a vacuum drying oven for 60 After drying at ℃ for 12 hours, it was pressed into a positive electrode piece with a diameter of 1.0 cm; the conductive polymer PPy adsorptio...

Embodiment 3

[0042] Preparation of conductive polymer poly(paraphenylene vinylene) (PEDOT) adsorption layer:

[0043] Mix conductive polymer PEDOT, carbon fiber and PAA in deionized water at a mass ratio of 5:1:4, heat and stir in a water bath for 5 hours to form a slurry with a solid content of 60%, and then repeatedly grind the slurry on a double-roll machine Press it into a film with a thickness of 1.5mm, dry it in a vacuum oven at 100°C for 10h, and then cut it into small discs with a diameter of 1.5cm to obtain the conductive polymer PEDOT adsorption layer.

[0044] Preparation of lithium-sulfur battery:

[0045] Mix elemental sulfur, SP, and PVDF in NMP solvent at a mass ratio of 6:2:2 to form a slurry with a solid content of 30% as the positive electrode material, which is coated on the aluminum foil positive electrode current collector, and placed in a vacuum drying oven for 60 After drying at ℃ for 12 hours, it was pressed into a positive electrode sheet with a diameter of 1.0 cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com