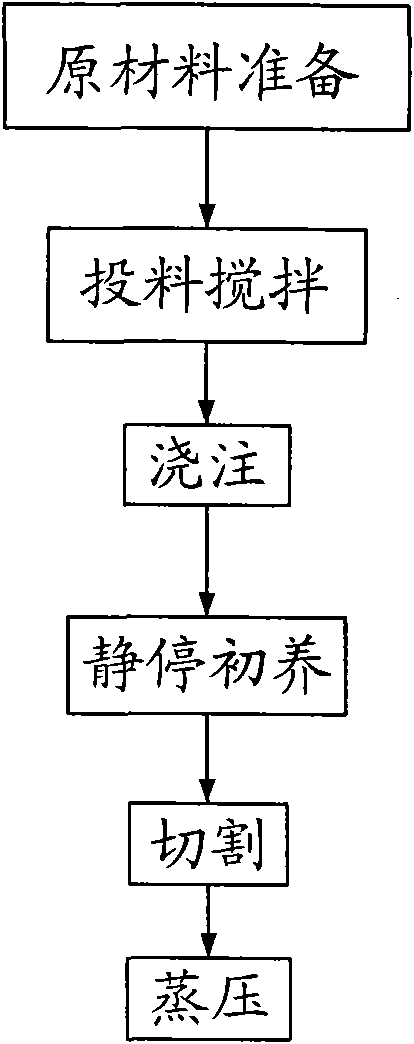

Production technology for concrete building block of autoclaving and air entraining of circulating fluid bed fly ash

A circulating fluidized bed, concrete block technology, used in manufacturing tools, clay preparation devices, mixing operation control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

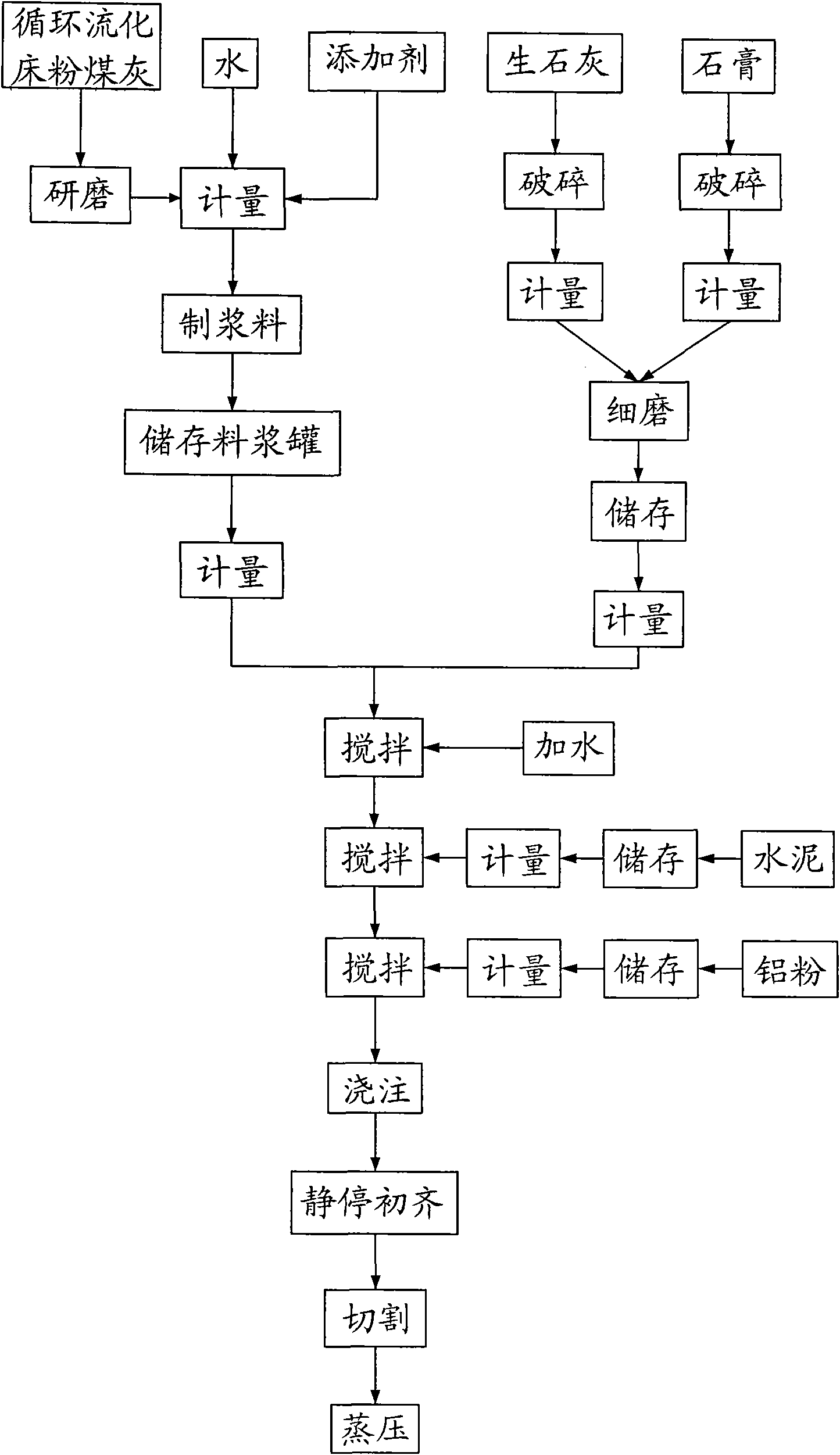

[0042] Embodiment one, such as figure 2 Shown:

[0043] 1. Raw material preparation

[0044]A. Grind 60 parts of circulating fluidized bed fly ash with a ball mill until the particle size is between 22-24um, add 54 parts of water and 1 part of additive and stir to make a slurry and store it in a slurry tank for later use. The slurry is fine The density is 12-16% (4900-hole square-hole sieve);

[0045] B. Crushing quicklime and gypsum with a jaw crusher respectively, then take 16 parts of quicklime after crushing and 3 parts of gypsum and mix them with a ball mill until the fineness is 8-15% (4900-hole square-hole sieve residue), then store Stand by in the mixing silo;

[0046] C. Measure 1 part of additive, 7 parts of cement, 0.07 part of aluminum powder, and 6 parts of water respectively and store them for later use.

[0047] 2. Feeding and stirring

[0048] First put the slurry of circulating fluidized bed fly ash into the mixer and start the mixer, then add the mixtur...

Embodiment 2

[0057] Embodiment two, still refer to figure 2 Shown:

[0058] 1. Raw material preparation

[0059] A. Grind 70 parts of circulating fluidized bed fly ash with a ball mill until the particle size is between 22-24um, add 63 parts of water and stir to make a slurry and store it in a slurry tank for later use;

[0060] B. Crushing quicklime and gypsum through a jaw crusher respectively, then take 23 parts of quicklime and 4 parts of gypsum after crushing, mix them with a ball mill and store them in a mixing bin for later use;

[0061] C. Measure 3 parts of additives, 10 parts of cement, 0.12 parts of aluminum powder, and 7 parts of water, respectively, and store them for later use.

[0062] 2. Feeding and stirring

[0063] Put the slurry of circulating fluidized bed fly ash into the mixer first, then start the mixer, then add the mixture of quicklime and gypsum and cement, and finally add aluminum powder and continue stirring for three minutes before stopping.

[0064] 3. Po...

Embodiment 3

[0072] Embodiment three, still refer to figure 2 Shown:

[0073] 1. Raw material preparation

[0074] A. Grind 65 parts of circulating fluidized bed fly ash with a ball mill until the particle size is between 22-24um, add 60 parts of water and stir to make a slurry and store it in a slurry tank for later use;

[0075] B. Crushing quicklime and gypsum through a jaw crusher respectively, then take 20 parts of quicklime and 3.5 parts of gypsum after crushing, mix them with a ball mill and store them in a mixing silo for use;

[0076] C. Measure 2 parts of additives, 9 parts of cement, 1 part of aluminum powder, and 5 parts of water respectively and store them for later use.

[0077] 2. Feeding and stirring

[0078] First put the slurry of circulating fluidized bed fly ash into the mixer and start the mixer, then add the mixture of quicklime and gypsum and stir for 60s, then add cement and stir for 60s, finally add aluminum powder and continue stirring for 60s before stopping....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com