Zinc oxide-metal lithium composite negative electrode and preparation method thereof, and metal lithium secondary battery

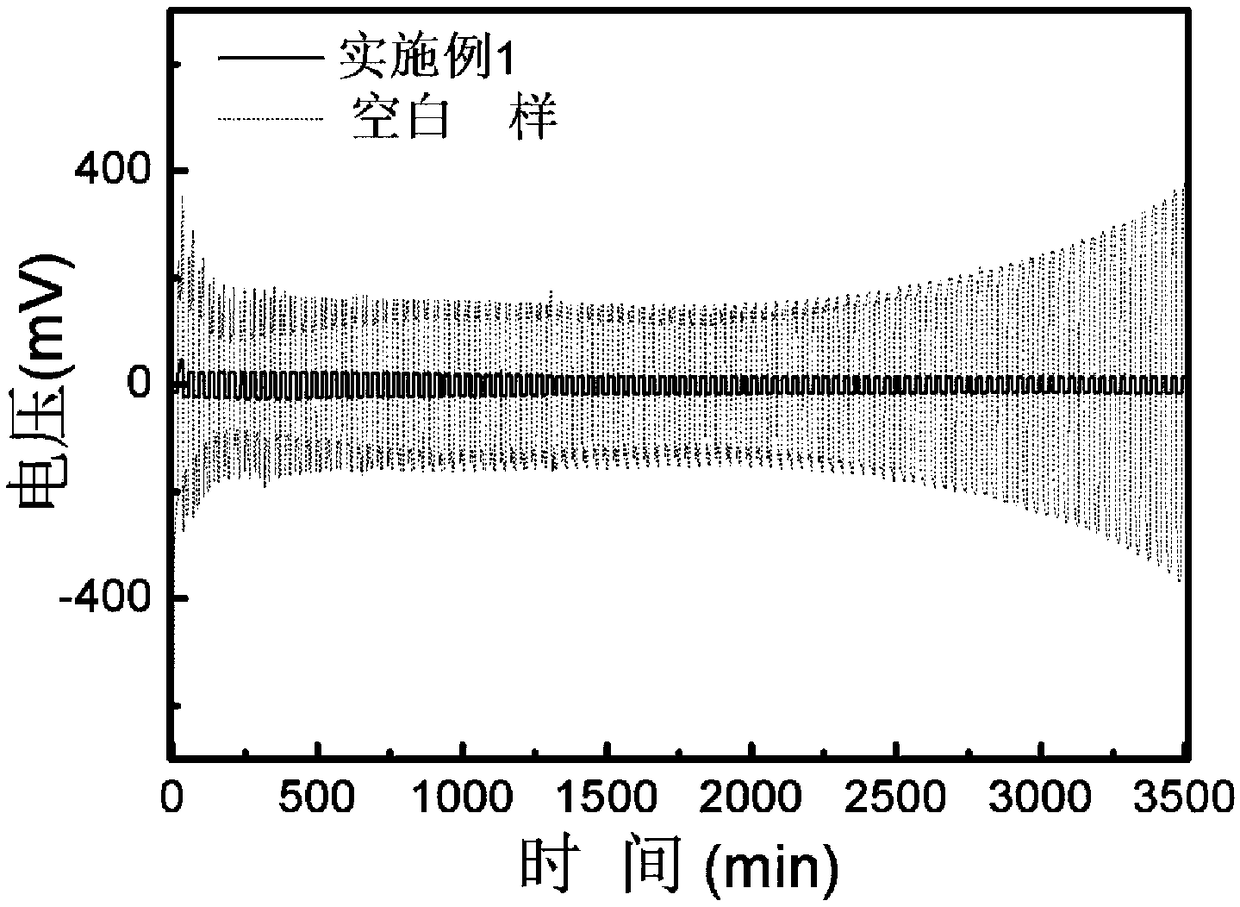

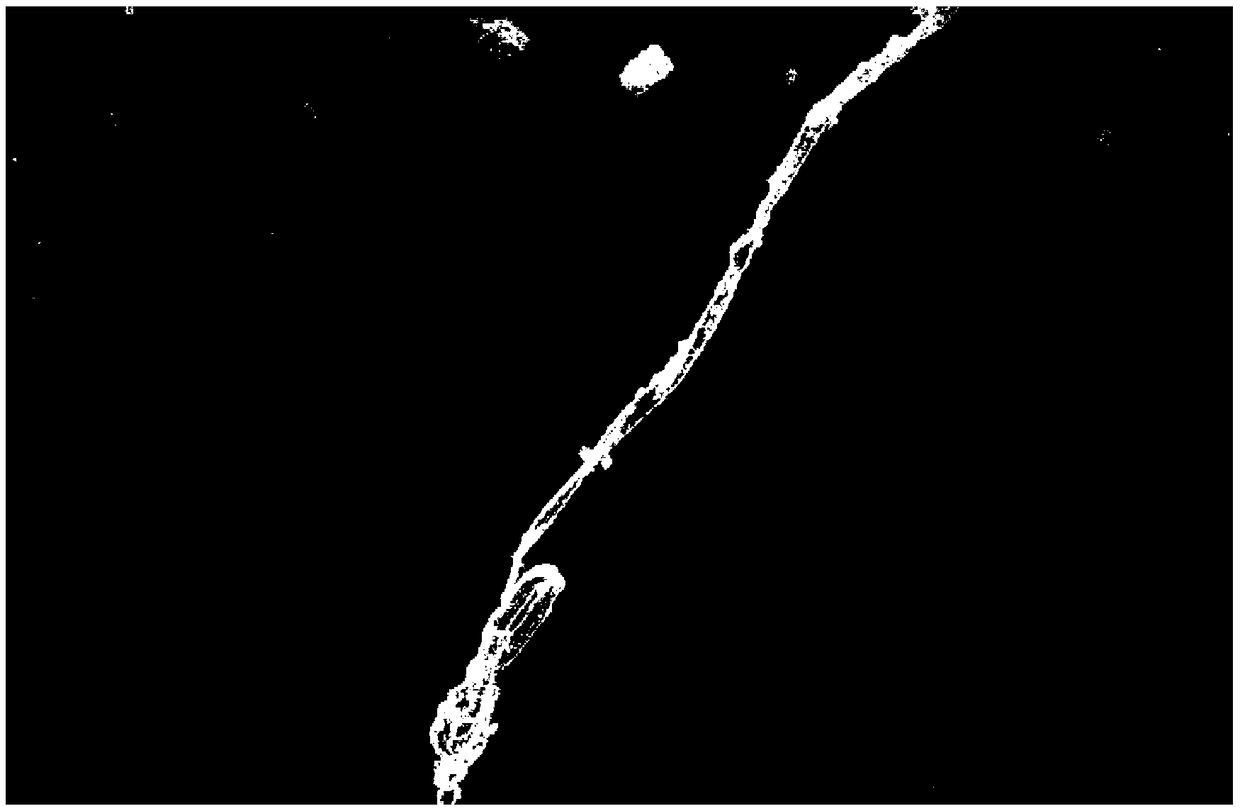

A secondary battery, zinc oxide technology, applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of reducing battery coulombic efficiency and cycle life, SEI rupture and regeneration, battery efficiency decline, etc., to achieve the purpose of inhibiting dendrites Growth, excellent cycle stability, effect of reducing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a zinc oxide-metal lithium composite negative electrode with a three-dimensional structure, comprising the following steps:

[0040] 1) Soak foamed copper slices in acetone, ethanol and deionized water in sequence, and ultrasonically clean them for 30 minutes at an ultrasonic frequency of 50 kHz; put the foamed copper after ultrasonic cleaning into a vacuum drying oven, and dry at 100°C for 10 minutes ;

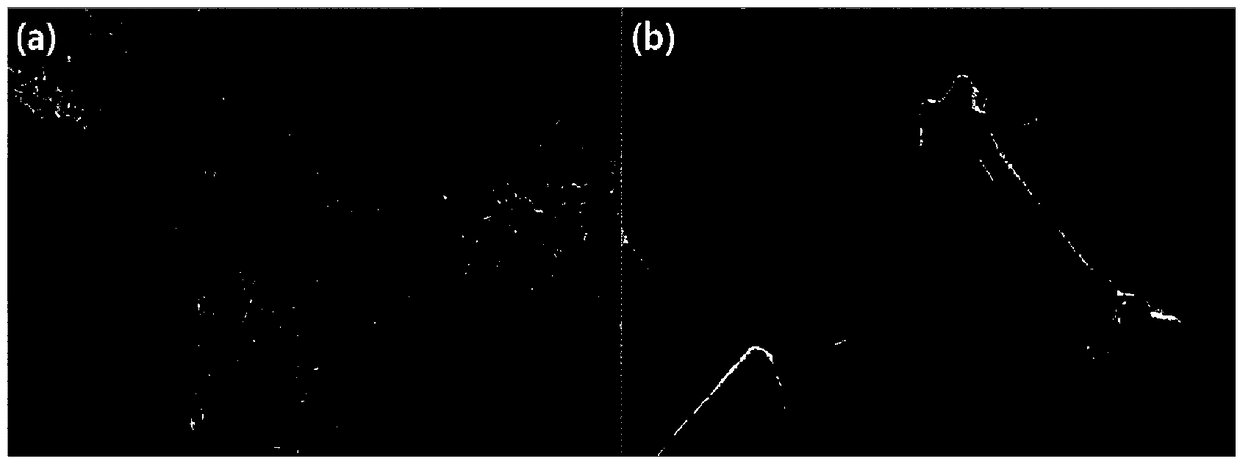

[0041] 2) Put the dried copper foam into 60mL of zinc nitrate solution with a concentration of 0.03mol / L, and then slowly add 7mL of concentrated ammonia water with a concentration of 13mol / L dropwise, and then hydrothermally react at 110°C for 4h. Deposit zinc hydroxide, then wash the foam copper with zinc hydroxide deposited with a large amount of deionized water, and finally put it in a vacuum drying oven, dry at 200°C for 1.5h, take it out after cooling, and it will be the foam deposited with zinc oxide nano-layer Copper (from figure 1 The ...

Embodiment 2

[0051] A method for preparing a zinc oxide-metal lithium composite negative electrode with a three-dimensional structure, comprising the following steps:

[0052] 1) Soak foamed copper slices in acetone, ethanol and deionized water in turn, and ultrasonically clean them for 60 minutes at an ultrasonic frequency of 30 kHz; put the foamed copper after ultrasonic cleaning into a vacuum drying oven and dry at 50°C for 60 minutes ;

[0053] 2) Put the dried copper foam into 3 mL of zinc nitrate solution with a concentration of 0.05 mol / L, and then slowly add 10 mL of ammonia water with a concentration of 13.5 mol / L dropwise, then hydrothermally react at 75 °C for 10 h, and the foam Deposit zinc hydroxide on the copper surface, then rinse the foamed copper with zinc hydroxide deposited with a large amount of deionized water, and finally put it in a vacuum drying oven, dry it at 120°C for 3 hours, and take it out after cooling to obtain the foam copper deposited with zinc oxide nano-...

Embodiment 3

[0061] A method for preparing a zinc oxide-metal lithium composite negative electrode with a three-dimensional structure, comprising the following steps:

[0062] 1) Soak foamed copper slices in acetone, ethanol and deionized water in sequence, and ultrasonically clean them for 50 minutes at an ultrasonic frequency of 40 kHz; put the foamed copper after ultrasonic cleaning into a vacuum drying oven, and dry at 70°C for 40 minutes ;

[0063] 2) Put the dried copper foam into 60mL of zinc nitrate solution with a concentration of 0.02mol / L, then slowly add 7mL of ammonia water with a concentration of 13.5mol / L dropwise, and react hydrothermally at 90°C for 6h. Deposit zinc hydroxide on the copper surface, then wash the foamed copper with zinc hydroxide deposited with a large amount of deionized water, and finally put it in a vacuum drying oven, dry it at 160°C for 2.5 hours, take it out after cooling, and it will be deposited with zinc oxide nano-layer Copper foam, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com