Sodium ion battery negative electrode material containing nitrogen and carbon coated bimetallic sulfide and preparation method thereof

A technology of sodium ion battery and negative electrode material, which is applied to battery electrodes, active material electrodes, negative electrodes, etc., to achieve the effects of simple preparation method, improved electrical conductivity, and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

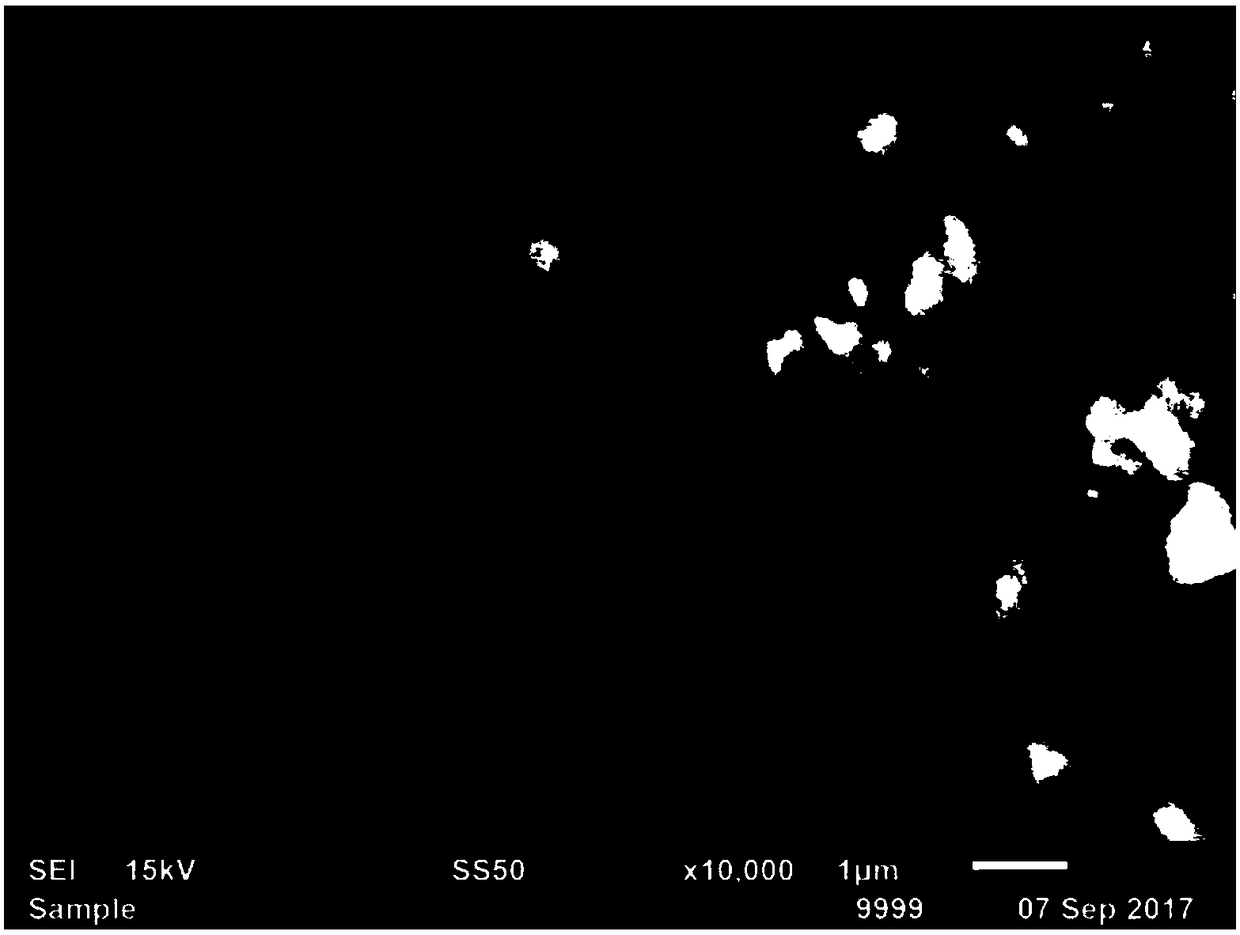

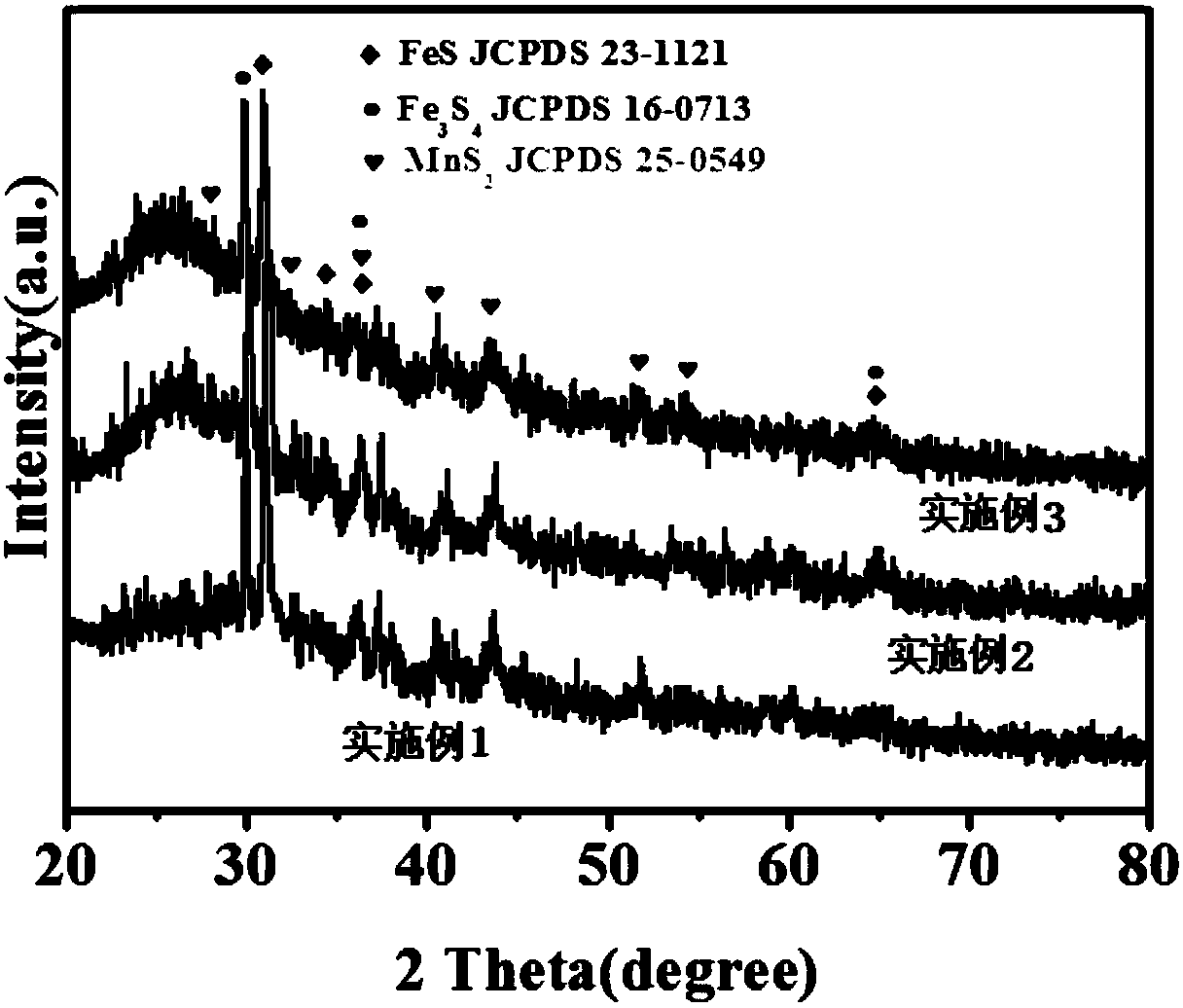

Embodiment 1

[0031] A preparation method of a nitrogen-containing carbon-coated bimetallic sulfide sodium ion battery negative electrode material:

[0032] Take 100mg of MnFePB in 100mL of distilled water and ultrasonically disperse for 20min, then add 0.25mL of pyrrole, and stir magnetically for 20min in ice bath. Slowly drop 100mL of 0.04M ammonium persulfate solution into it, about 2h to finish. Keep stirring under the ice bath, continue the reaction for 6h to complete the polymerization. After suction filtration with a suction filter pump, dry in a vacuum oven at 60°C for 24 hours to obtain polypyrrole-coated MnFePB. The obtained polypyrrole-coated MnFePB and thiourea were placed in an aluminum oxide cauldron at a mass ratio of 1:2, mixed evenly, and heated from room temperature to 500 °C at a rate of 1 °C / min under an argon atmosphere. , insulation 2h, that is.

Embodiment 2

[0034] A preparation method of a nitrogen-containing carbon-coated bimetallic sulfide sodium ion battery negative electrode material:

[0035] Take 100mg of MnFePB and ultrasonically disperse in 100mL of distilled water for 20min, then add 0.5mL of pyrrole, and stir magnetically for 20min in ice bath. Slowly drop 100mL of 0.04M ammonium persulfate solution into it, about 2h to finish. Keep stirring under the ice bath, continue the reaction for 6h to complete the polymerization. After suction filtration with a suction filter pump, dry in a vacuum oven at 60°C for 24 hours to obtain polypyrrole-coated MnFePB. The obtained polypyrrole-coated MnFePB and thiourea were placed in an aluminum oxide cauldron at a mass ratio of 1:2, mixed evenly, and heated from room temperature to 500 °C at a rate of 1 °C / min under an argon atmosphere. , insulation 2h, that is.

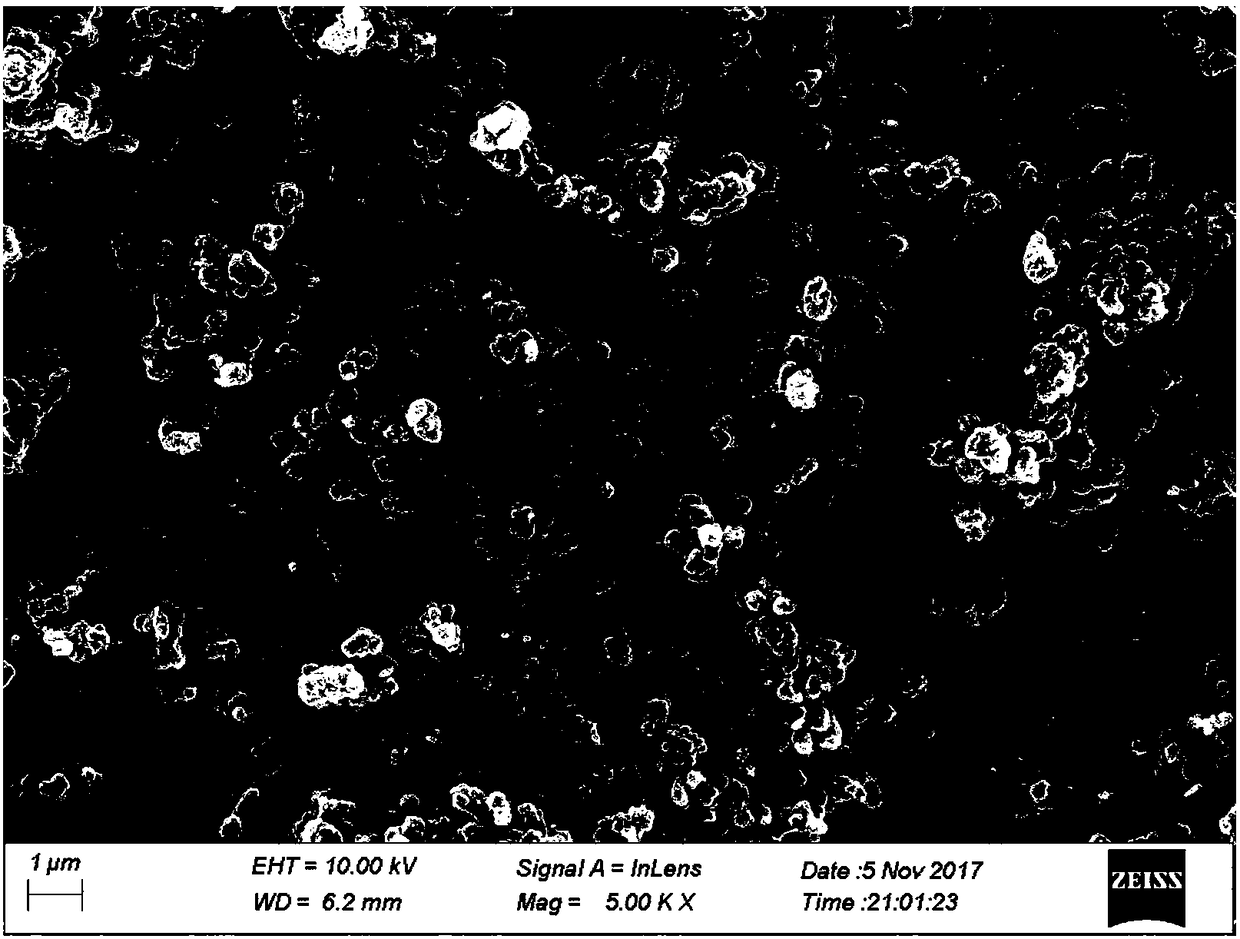

Embodiment 3

[0037] A preparation method of a nitrogen-containing carbon-coated bimetallic sulfide sodium ion battery negative electrode material:

[0038]Take 100mg of MnFePB and ultrasonically disperse in 100mL of distilled water for 20min, then add 1mL of pyrrole, and stir magnetically for 20min in ice bath. Slowly drop 100mL of 0.04M ammonium persulfate solution into it, about 2h to finish. Keep stirring under the ice bath, continue the reaction for 6h to complete the polymerization. After suction filtration with a suction filter pump, dry in a vacuum oven at 60°C for 24 hours to obtain polypyrrole-coated MnFePB. The obtained polypyrrole-coated MnFePB and thiourea were placed in an aluminum oxide cauldron at a mass ratio of 1:2, mixed evenly, and heated from room temperature to 500 °C at a rate of 1 °C / min under an argon atmosphere. , insulation 2h, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com