Cobalt sulfide preparation method

A technology of cobalt sulfide and thiourea, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve the problems of difficult operation, high energy consumption, high cost, and achieve good charge-discharge performance, high specific surface area, and excellent capacitance. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preparation method of cobalt sulfide of the present invention, step is as follows:

[0017] Dissolve 1.72mmol cobalt nitrate and 1.31mmol thiourea in the solvent, seal it in a 25mL stainless steel autoclave lined with polytetrafluoroethylene, react at 160°C for 24h, then cool it to room temperature, and take out the precipitate , washed twice with deionized water and absolute ethanol, and finally dried the product at 60°C for 24 hours to obtain cobalt sulfide with a hollow structure. The solvent is composed of a mixture of n-propanol and water in a volume ratio of 1:1, or a mixture of methanol and water in a volume ratio of 1:1, or a mixture of hydrogen peroxide and water in a volume ratio of 3:7.

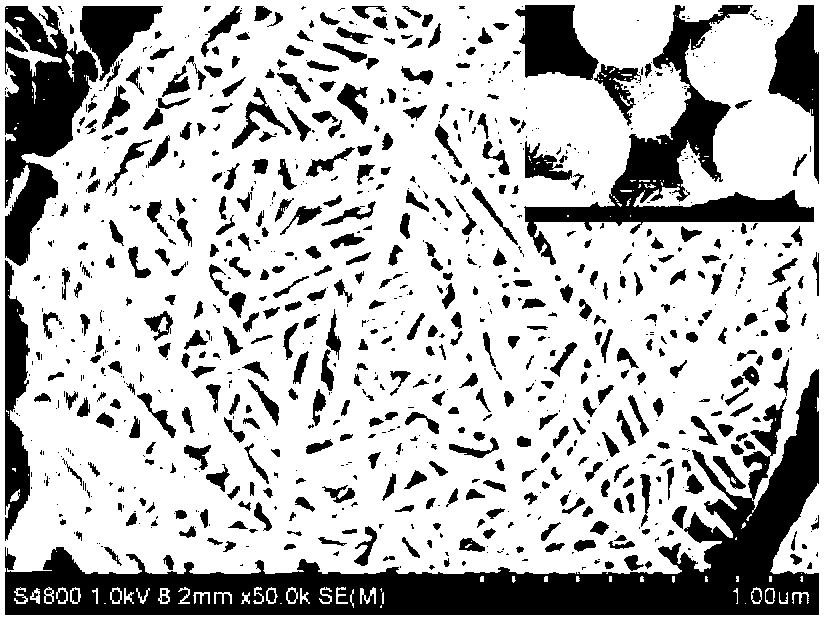

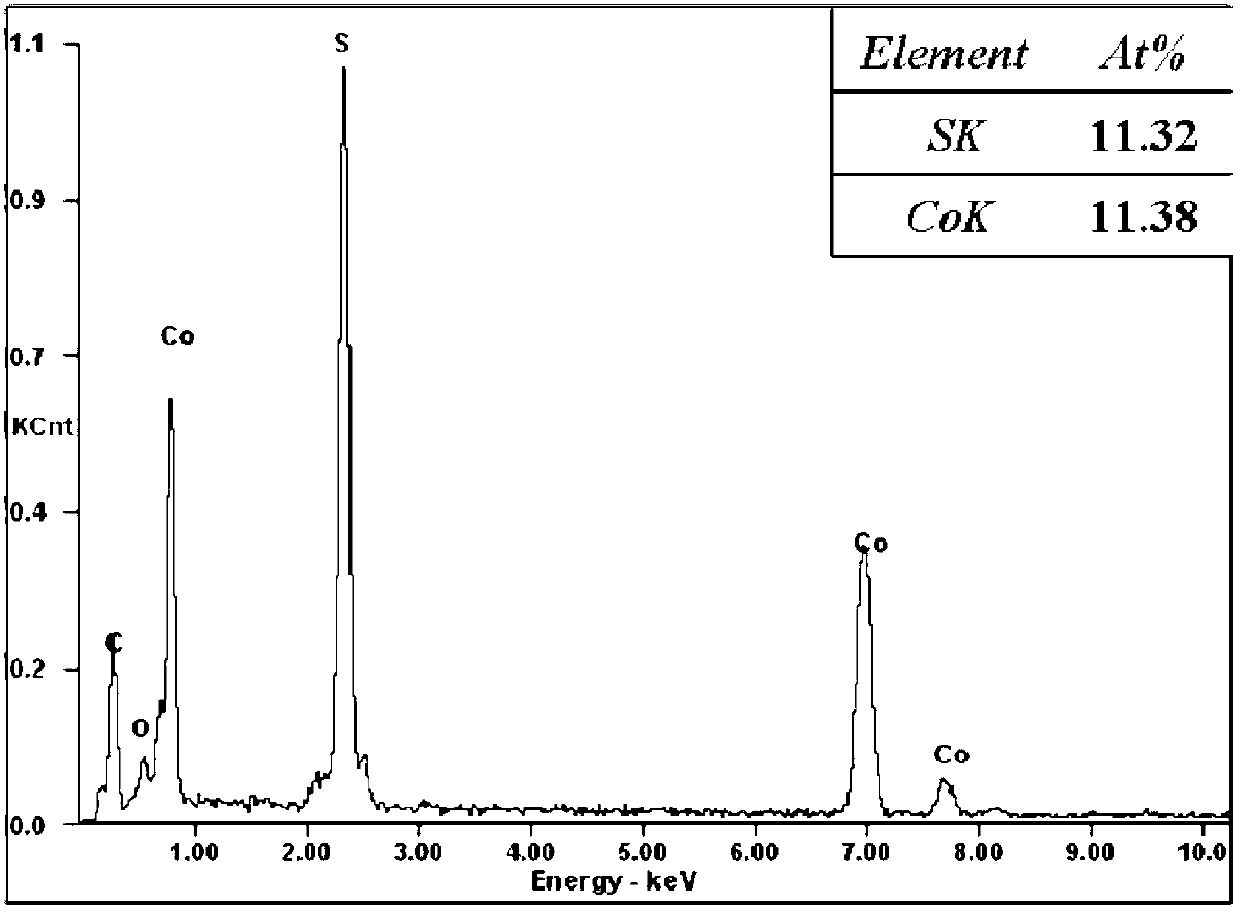

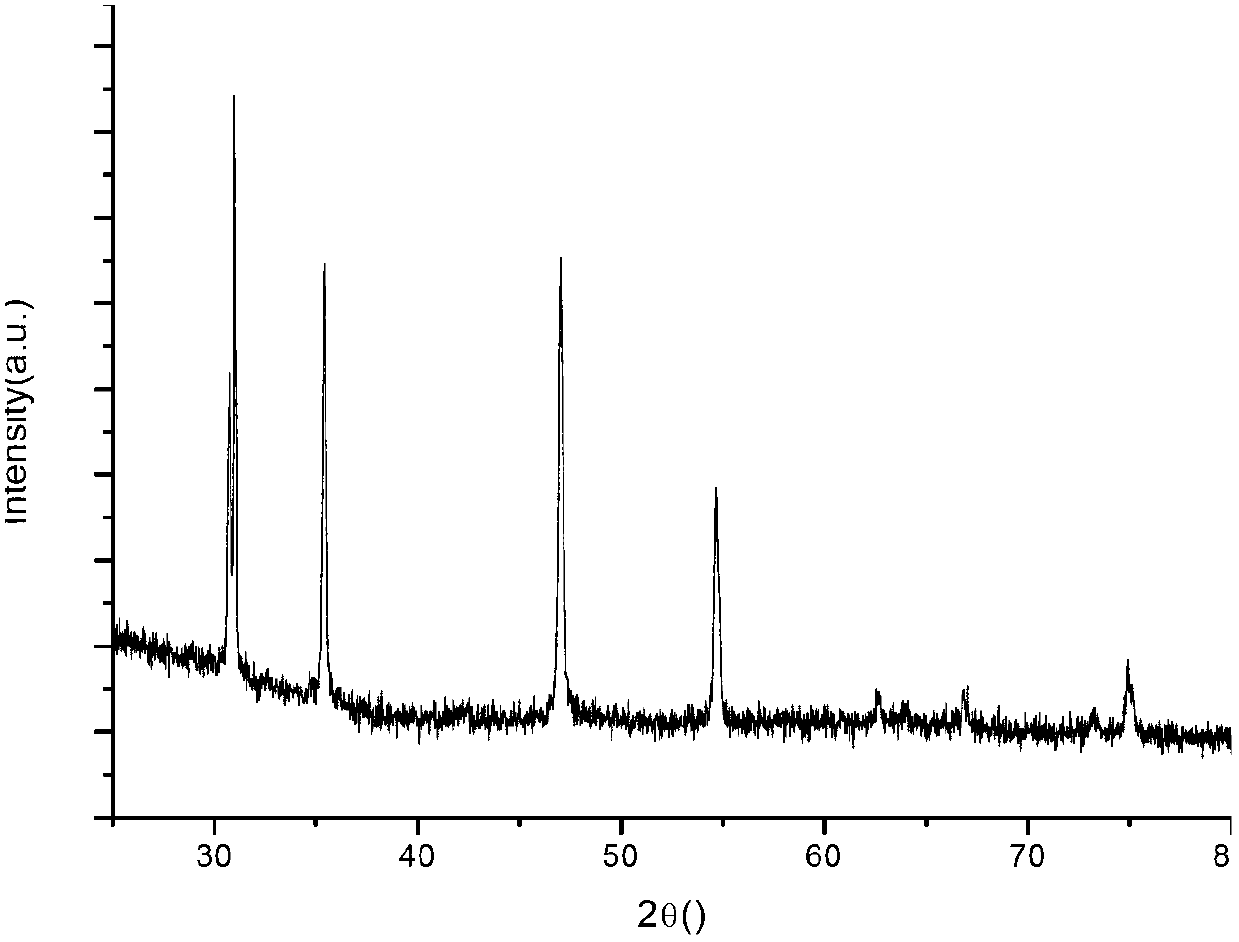

[0018] Attached below Figure 1-3 Characterization and analysis of materials.

[0019] 1. Use SEM to observe the surface morphology of the CoS hollow structure: use a JSM-5610LV scanning electron microscope to observe the surface morphology of the CoS hollow structure....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com