Cobalt sulfide material, preparation method and application of cobalt sulfide material

A technology of cobalt sulfide and cobalt chloride hexahydrate, which is applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve problems such as complex synthesis methods, and achieve the effects of simple preparation methods, good electrocatalytic activity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

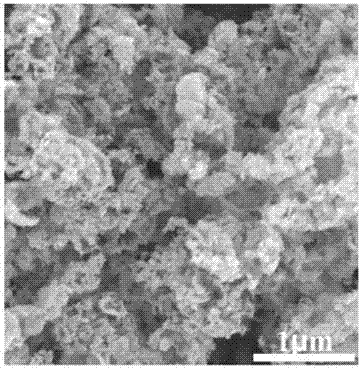

Image

Examples

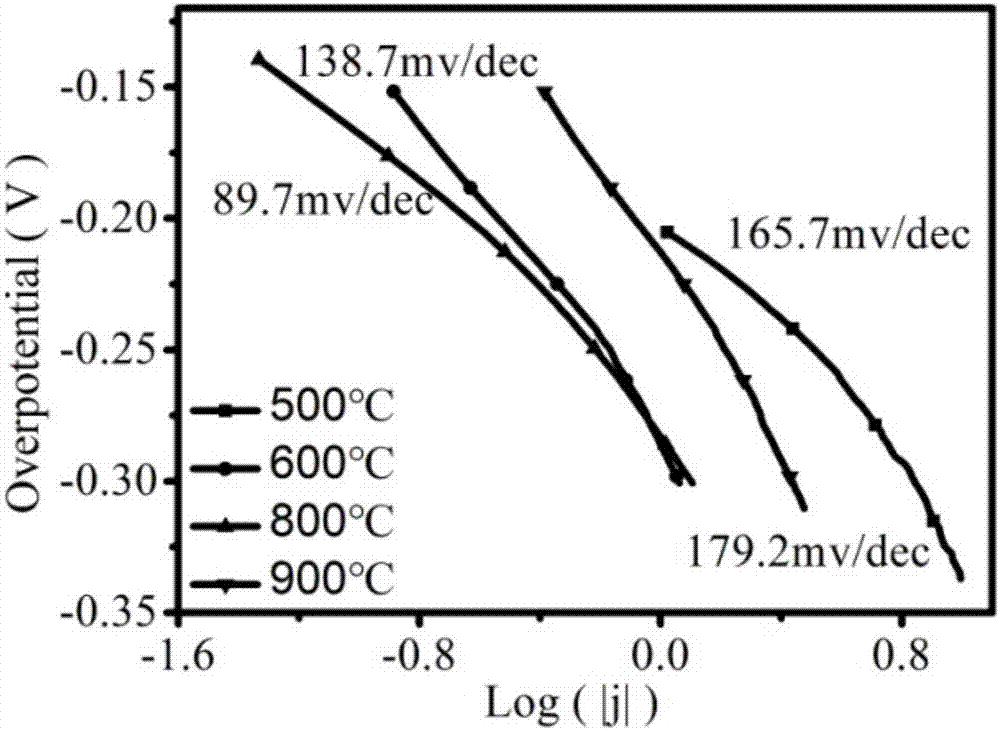

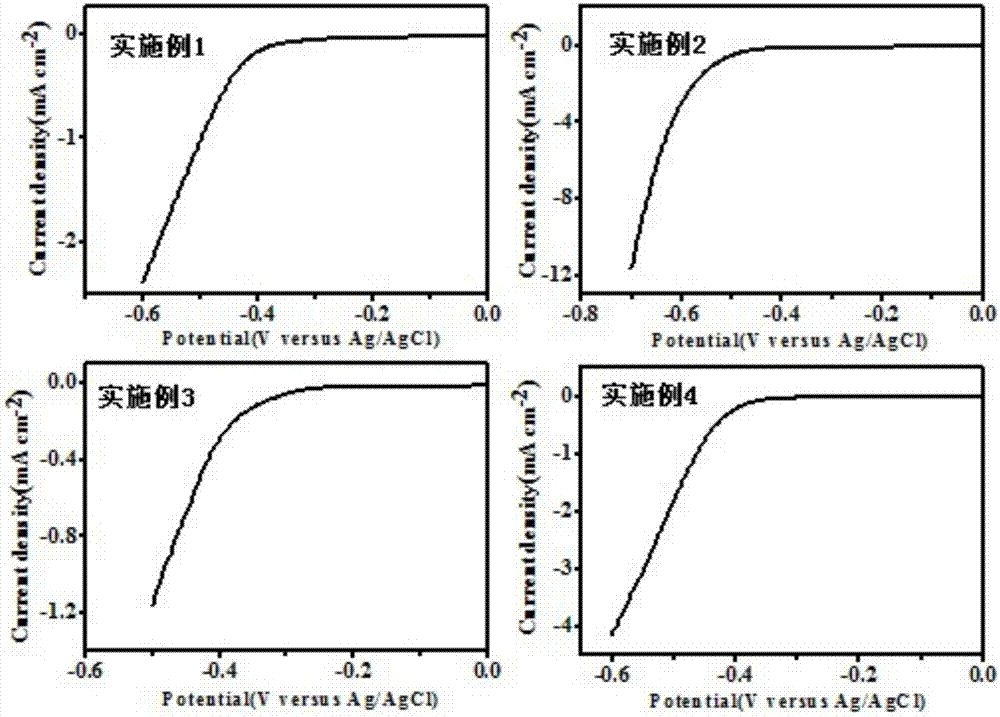

Embodiment 1

[0030] Cobalt sulfide materials are prepared by the following steps:

[0031] (1) Sodium dimethyldithiocarbamate and cobalt chloride hexahydrate were mixed in a 500ml beaker at a molar ratio of 2:1, 200ml to 400ml of water was added, stirred at room temperature for 10min to 30min, and a solid sample was obtained by suction filtration. Dry the sample in an oven at 100°C for 8h to 12h;

[0032] (2) 1 g of the product obtained in step (1) is placed in a tube furnace, and under the protection of argon, the temperature rises from room temperature to 500 °C at a rate of 5 °C / min, and is kept at this temperature for 2 hours. After cooling to room temperature, the sample was taken out to obtain a cobalt sulfide material.

Embodiment 2

[0034] The preparation method of cobalt sulfide material refers to Example 1, the difference is that in step (2), the product is raised from room temperature to 600° C. in a tube furnace at a heating rate of 5° C. / min.

Embodiment 3

[0036] The preparation method of cobalt sulfide material refers to Example 1, the difference is that in step (2), the product is raised from room temperature to 800° C. in a tube furnace at a heating rate of 5° C. / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com