Preparation method of thermal battery positive electrode material, and thermal battery made of thermal battery positive electrode material

A positive electrode material and thermal battery technology, applied in the field of chemical materials, can solve the problems of high price and high resistivity, and achieve the effect of low price, low internal resistance and high working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

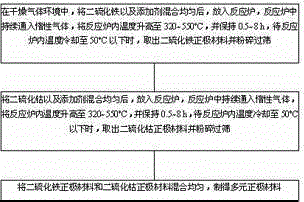

Method used

Image

Examples

Embodiment 1

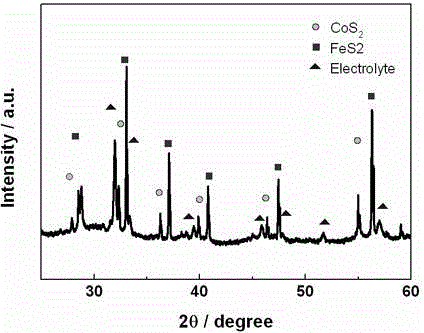

[0026] Example 1. After mixing iron disulfide, cobalt disulfide, electrolyte LiF-LiCl-LiBr and lithium oxide in a mass ratio of 65:20:20:5, perform lithiation treatment, wherein the mass percentage of the electrolyte is: LiF Accounted for 9.6%, LiCl accounted for 22.0%, LiBr accounted for 68.4%. figure 2 is the X-ray diffraction (XRD) pattern of the obtained multi-element cathode material.

Embodiment 2

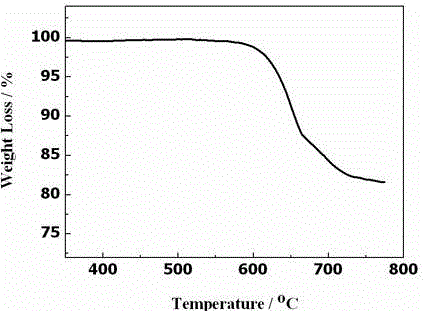

[0027] Example 2, after mixing iron disulfide, cobalt disulfide, spacer powder (containing 50 wt.% LiCl-LiBr-KBr and 50 wt.% magnesium oxide) and lithium oxide in a mass ratio of 70:20:9:1 , for lithiation treatment, wherein the mass percentage of the electrolyte is: LiCl accounts for 12.05%, LiBr accounts for 36.54%, and KBr accounts for 51.41%. image 3 It is the thermogravimetric analysis (TGA) diagram of the obtained multi-element cathode material.

Embodiment 3

[0028] Example 3. After mixing iron disulfide, electrolyte LiCl-KCl and lithium sulfide uniformly in a mass ratio of 20:60:15:5, lithiation treatment is carried out, wherein the mass percentage of the electrolyte is: LiCl accounts for 45%, KCl accounts for 45%. 55%;

[0029] After cobalt disulfide, electrolyte LiCl-KCl and lithium sulfide are uniformly mixed in a mass ratio of 20:60:15:5, lithiation treatment is performed, wherein the mass percentage of the electrolyte is: LiCl accounts for 45%, KCl accounts for 55%;

[0030] Mix the above-mentioned two materials evenly to prepare a multi-element positive electrode material.

[0031] The above binary LiCl-KCl electrolyte was mixed with magnesium oxide at a mass ratio of 60:40 to prepare the spacer powder.

[0032] Using the multi-component positive electrode material in this example as the positive electrode, combine the separator powder and the lithium-boron alloy negative electrode of this example to prepare a single batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com