Carbon fiber supported cobalt sulfide nanosheet catalyst and application thereof

A cobalt sulfide and nanosheet technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low activity of cracked water, and achieve good reproducibility, high controllability, Mild and simple effect of synthetic method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 1.25g of cobalt acetate tetrahydrate and 0.38g of thiourea in 28mL of ethylene glycol, put the resulting solution into a 50mL reactor, and add 1×5cm 2 The carbon cloth was reacted at 200°C for 20 hours, and the product was washed and dried at 60°C for 2 hours to obtain a carbon fiber-supported cobalt sulfide nanosheet catalyst.

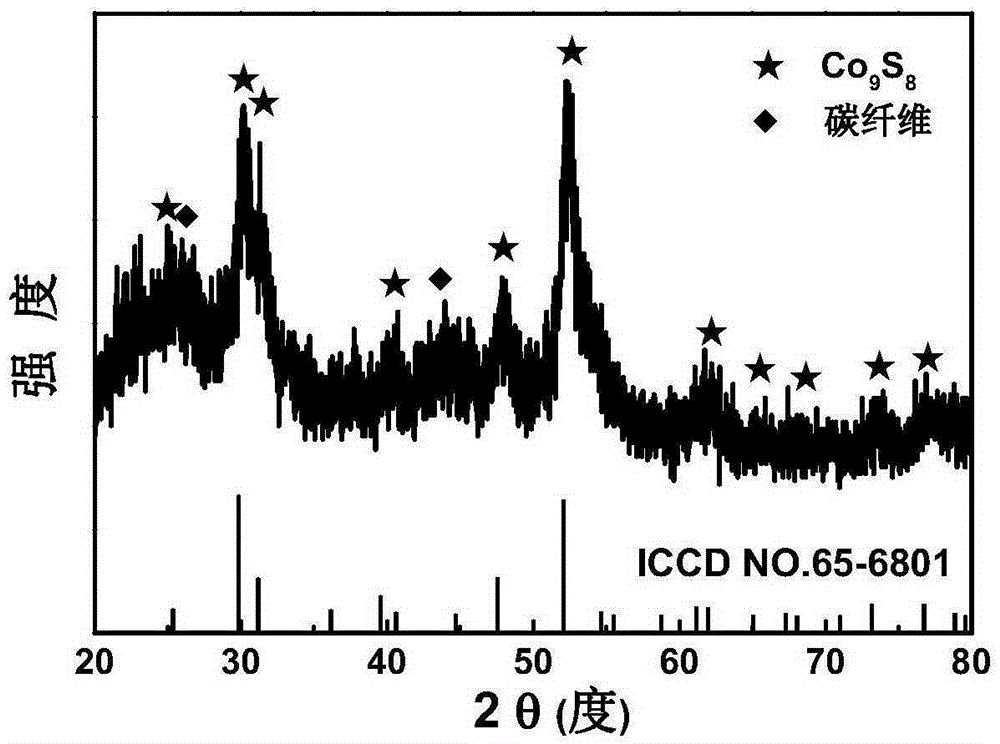

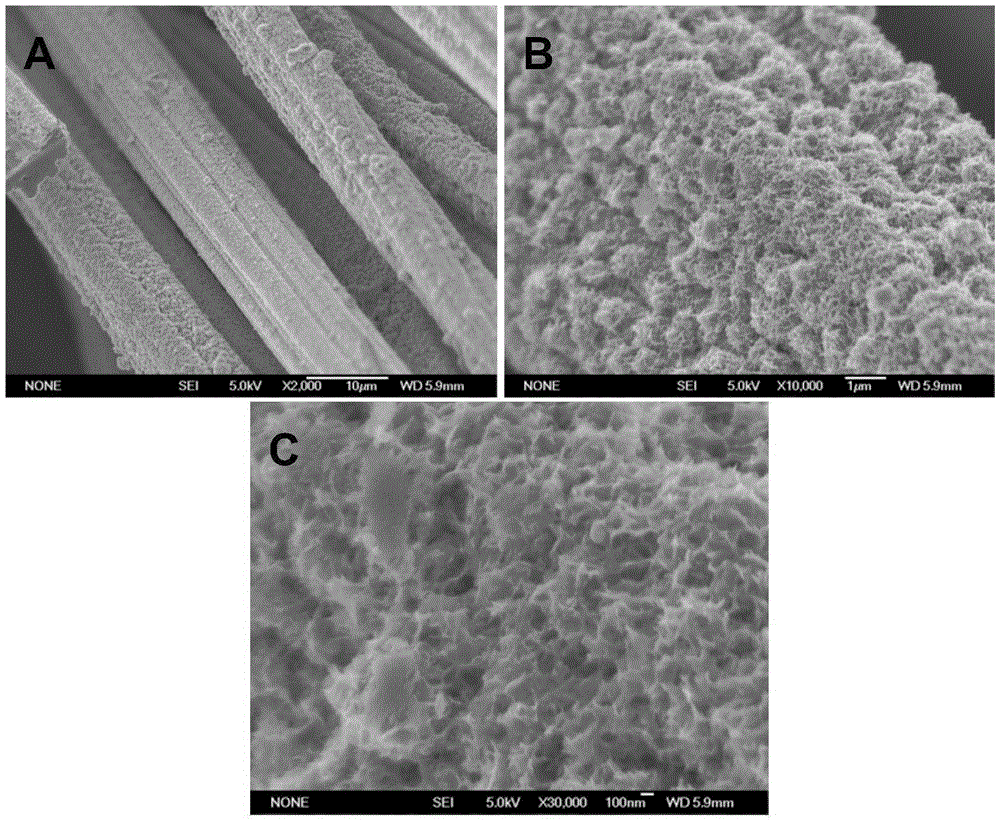

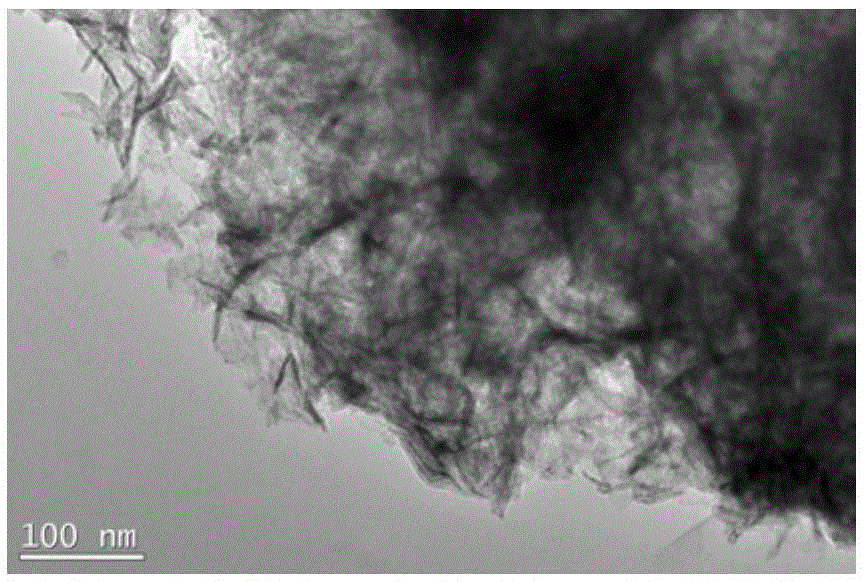

[0030] The necessary structure and properties of the materials prepared by the above method were studied. figure 1 The XRD spectrum of the obtained carbon fiber-loaded cobalt sulfide nanosheets shows that Co 9 S 8 . figure 2 It is the SEM photo of the obtained carbon fiber supported cobalt sulfide nanosheets, A and B can be seen that Co 9 S 8 The nanosheets are evenly loaded on the carbon fiber, and the Co 9 S 8 It is an extremely thin nanosheet structure. Figure 4 It is the TEM photo of the obtained carbon fiber supported cobalt sulfide nanosheets, it can be seen that the Co 9 S 8 The thickness of the nano sheet is 4-7nm. ...

Embodiment 2

[0036] Same as Example 1, except that the amount of ethylene glycol is changed to 36mL, and the current density reaches 10mA / cm 2 , requires an overpotential of 196mV.

Embodiment 3

[0038] Same as Example 1, except that the amount of ethylene glycol is changed to 24mL, and the current density reaches 10mA / cm 2 , requires an overpotential of 200mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com