Method for preparing hydrolysis-regulated nickel cobalt sulfide/carbon cloth porous supercapacitor electrode material

A technology of supercapacitor electrodes and nickel-cobalt sulfide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problems of reduced specific surface area of materials and decreased energy storage properties of electrode materials, and achieve large specific surface area and improved Capacitive properties and rate performance, effect of high-efficiency contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

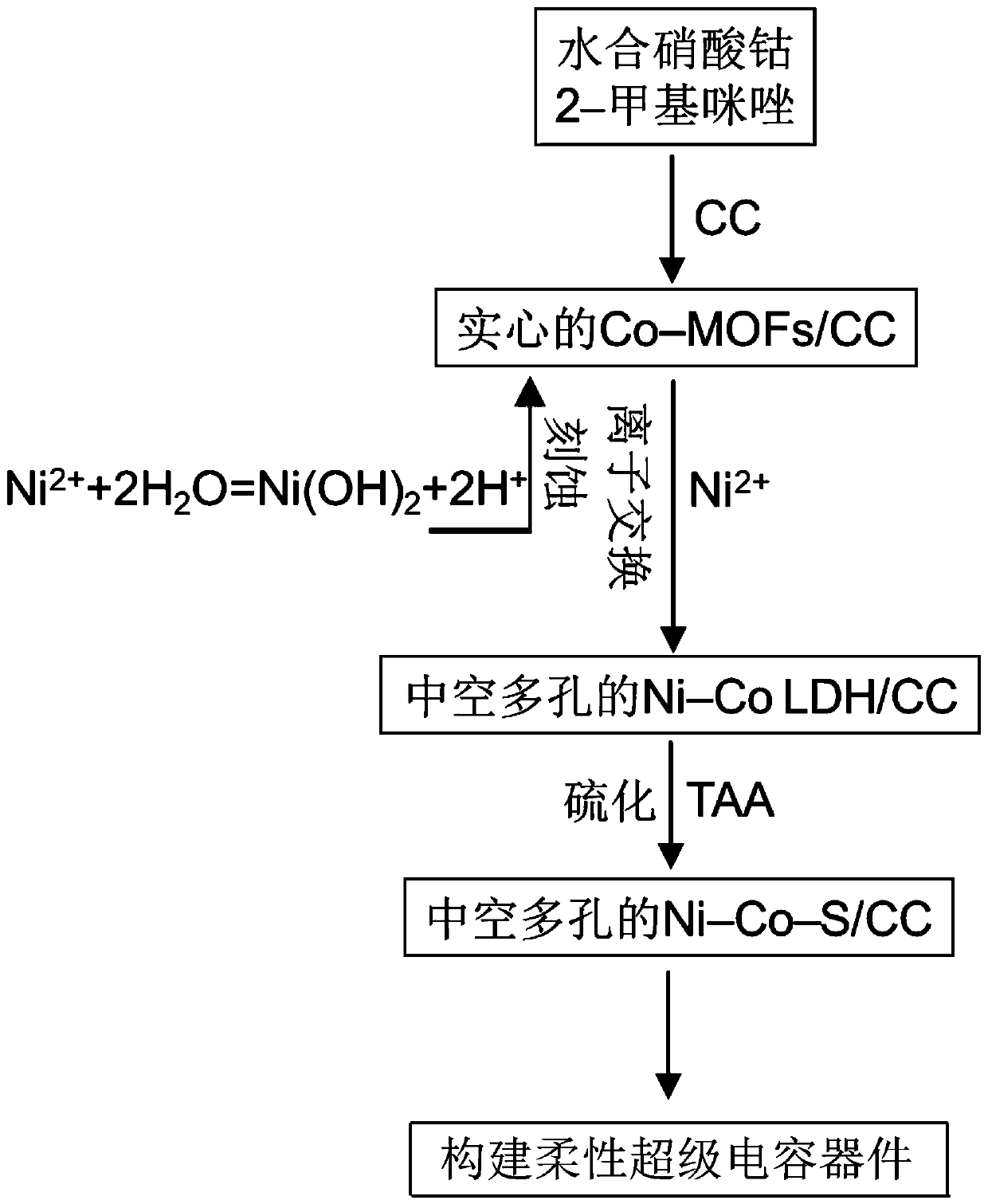

[0031] figure 1 It is a schematic diagram of the preparation route of the present invention. The present invention prepares cobalt-based metal-organic frameworks (Co-MOFs) composites grown on carbon cloth, porous nickel-cobalt layered double hydroxide / carbon cloth (Ni-Co LDH / CC) composites and the preparation of porous nickel-cobalt sulfide / carbon cloth (Ni-Co-S / CC) composites, the prepared carbon cloth-based fabric has multiple valence states, large specific surface area and high electrical activity. The hollow and porous morphology of binary metal sulfides plays a crucial role in enhancing the performance of energy storage devices.

[0032] Step 1. Preparation of Co-MOFs composite grown on carbon cloth:

[0033] Soak the carbon cloth in nitric acid for 9-24h, and then wash it with distilled water. Use hydrated cobalt nitrate and 2-methylimidazole as the precursors of the metal ion center and organic ligand respectively, dissolve and mix in the solvent, immerse the carbon ...

Embodiment 1

[0045] (1) Soak the carbon cloth in nitric acid for 10 h, and wash it with distilled water. Dissolve 1 mmol of cobalt nitrate hydrate and 8 mmol of 2-methylimidazole in 30 ml of methanol respectively, stir and mix, then immerse the treated carbon cloth (2 cm*5 cm) in the mixture, stir and react for 5 h , Take the sample out, wash it with distilled water, and dry it in a constant temperature drying oven at 60°C.

[0046] (2) Dissolve 2 mmol of hydrated nickel nitrate in 30 ml of methanol, immerse the sample obtained in step (1) into the nickel nitrate solution, stir and react for 10 min, take out the sample, and wash with distilled water and ethanol respectively.

[0047] (3) Dissolve 6 mmol thioacetamide in 30 ml ethanol solution, place the thioacetamide solution in a 50 ml hydrothermal kettle, and immerse the sample obtained in step (2) into the solution, and react at 120°C After 3 h, the samples were taken out after the reaction, washed with distilled water and ethanol resp...

Embodiment 2

[0055] (1) Soak the carbon cloth in nitric acid for 10 h, and wash it with distilled water. Dissolve 1 mmol of cobalt nitrate hydrate and 8 mmol of 2-methylimidazole in 30 ml of methanol respectively, stir and mix, then immerse the treated carbon cloth (2 cm*5 cm) in the mixture, stir and react for 5 h , Take the sample out, wash it with distilled water, and dry it in a constant temperature drying oven at 60°C.

[0056] (2) Dissolve 2 mmol of hydrated nickel nitrate in 30 ml of methanol, immerse the sample obtained in step (1) into the nickel nitrate solution, stir and react for 20 min, take out the sample, and wash with distilled water and ethanol respectively.

[0057] (3) Dissolve 6 mmol of thioacetamide in 30 ml of ethanol solution, place the thioacetamide solution in a 50 ml hydrothermal kettle, and immerse the sample obtained in step (2) into the solution, and react at 120°C After 3 h, the samples were taken out after the reaction, washed with distilled water and ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com