Method for quickly preparing cobalt sulfide/graphene hydrogel nano composite material

A technology of graphene hydrogel and nanocomposite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of reducing the effective specific surface area of the composite, reducing the electrochemical performance, and experimental operation Complicated problems, to achieve excellent electrochemical performance, convenient testing, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

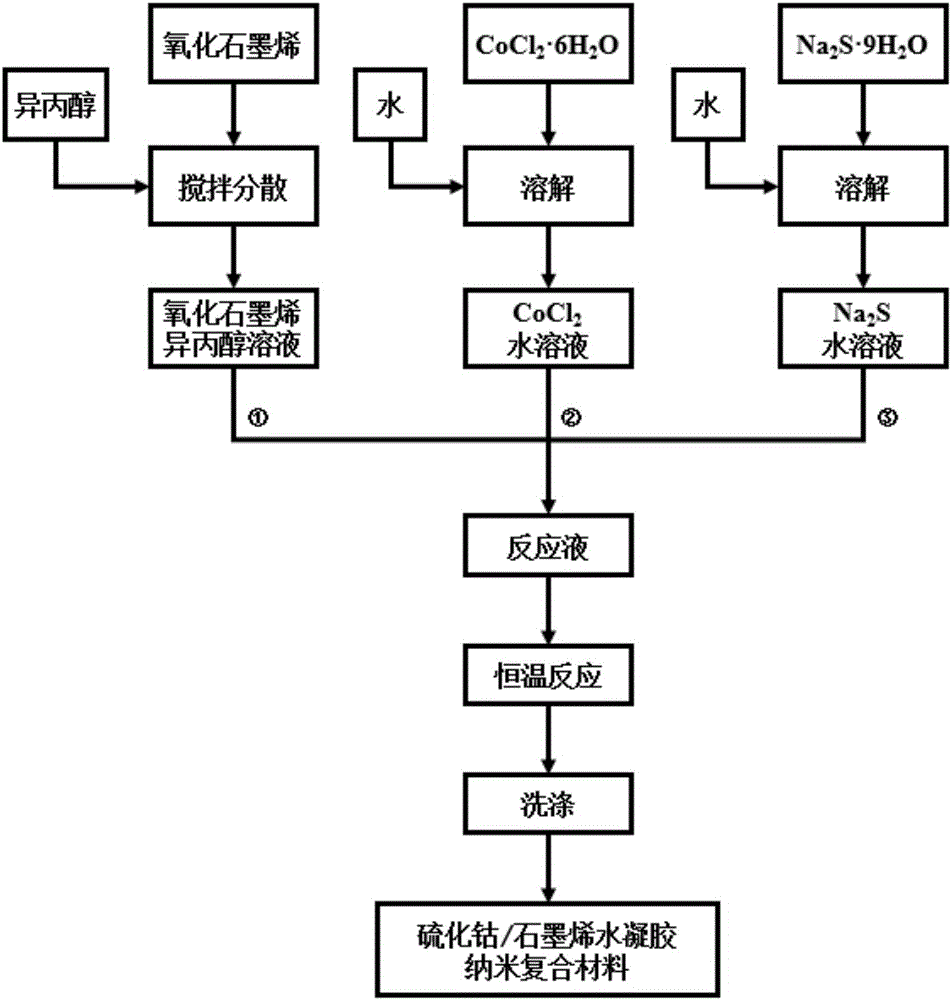

[0027] Step 1: Dissolve 106mg graphene oxide in 15mL isopropanol, stir to fully disperse (60min);

[0028] Step 2: 2.14gCoCl 2 ·6H 2 O with 2.14gNa 2 S·9H 2 O was dissolved in 7.5 mL of water respectively to obtain CoCl 2 Aqueous solution and Na 2 S aqueous solution;

[0029] Step three: the graphene oxide alcohol solution obtained in step one, the CoCl obtained in step two 2 Aqueous solution, Na 2 The S aqueous solution was placed in the container in turn to obtain the reaction solution, and then placed in a closed reaction kettle for constant temperature reaction at 220 ° C for 18 hours;

[0030] Step 4: After washing the product obtained in Step 3, the cobalt sulfide / graphene hydrogel nanocomposite material is obtained.

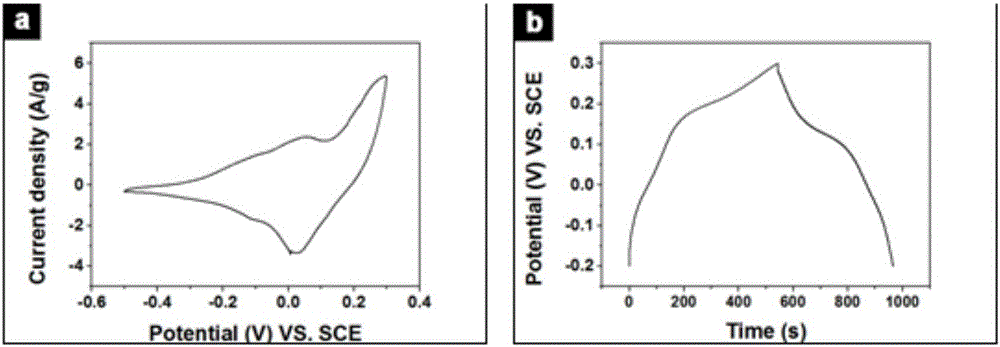

[0031] The resulting product and its freeze-dried photos are attached figure 2 It is shown that the product has a three-dimensional hydrogel structure. The freeze-dried samples were made into electrodes for electrochemical testing. The cyclic vo...

Embodiment 2

[0033] Step 1: Dissolve 53mg graphene oxide in 10.5mL isopropanol, stir to fully disperse (60min);

[0034] Step 2: 1.07gCoCl 2 ·6H 2 O with 1.07gNa 2 S·9H 2 O was dissolved in 5.25mL water respectively;

[0035] Step three: the graphene oxide alcohol solution obtained in step one, the CoCl obtained in step two 2 Aqueous solution, Na 2 The S aqueous solution was placed in the container in turn to obtain the reaction solution, and then placed in a closed reaction kettle for constant temperature reaction at 200 ° C for 18 hours;

[0036] Step 4: After washing the product obtained in Step 3, the cobalt sulfide / graphene hydrogel nanocomposite material is obtained.

[0037] Calculated by the constant current charge and discharge curve, the specific capacitance of the product obtained in this embodiment is 394.0 F / g.

Embodiment 3

[0039] Step 1: Dissolve 106mg graphene oxide in 7.5mL isopropanol, stir to fully disperse (45min);

[0040] Step 2: 428mgCoCl 2 ·6H 2 O with 428mgNa 2 S·9H 2 O was dissolved in 11.25mL water respectively;

[0041] Step three: the graphene oxide alcohol solution obtained in step one, the CoCl obtained in step two 2 Aqueous solution, Na 2 The aqueous solution of S was placed in the container in turn to obtain the reaction liquid, and then placed in a closed reaction kettle for constant temperature reaction at 180°C for 12 hours;

[0042] Step 4: After washing the product obtained in Step 3, the cobalt sulfide / graphene hydrogel nanocomposite material is obtained.

[0043] Calculated by the constant current charge and discharge curve, the specific capacitance of the product obtained in this embodiment is 298.8 F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com