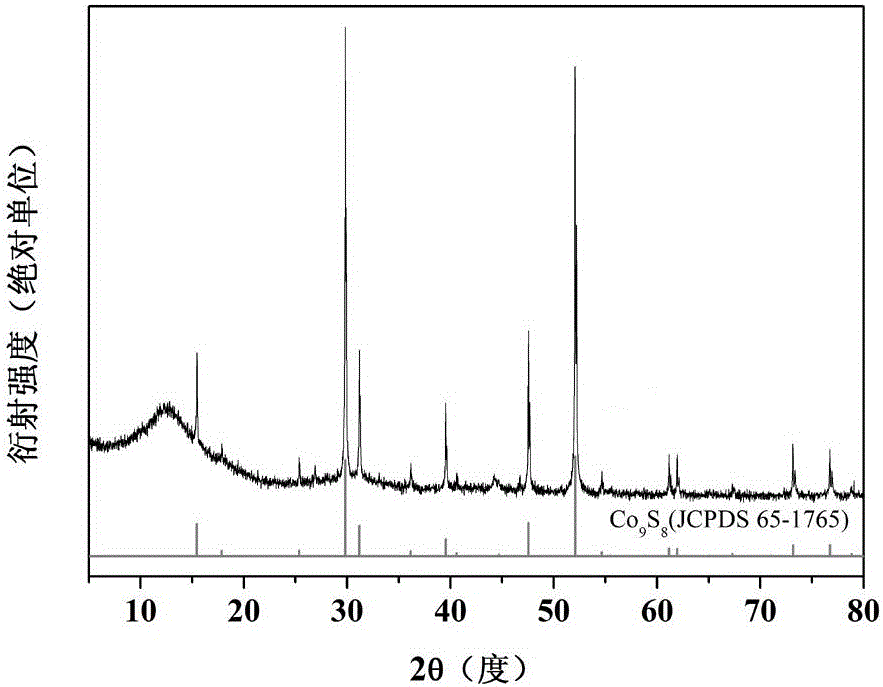

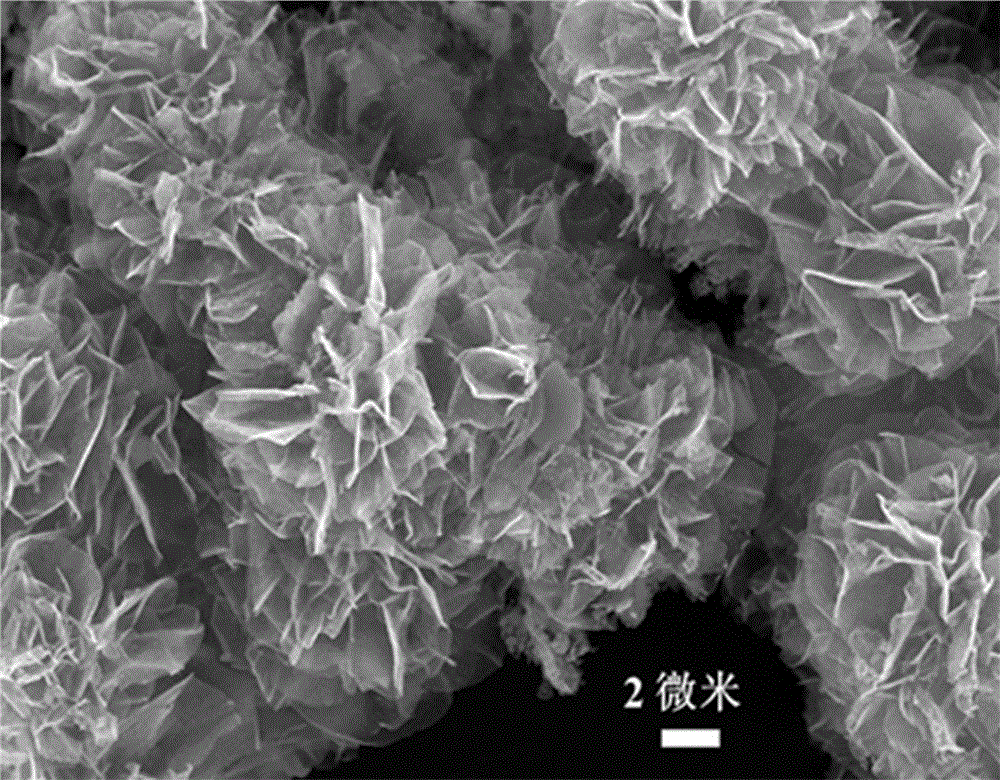

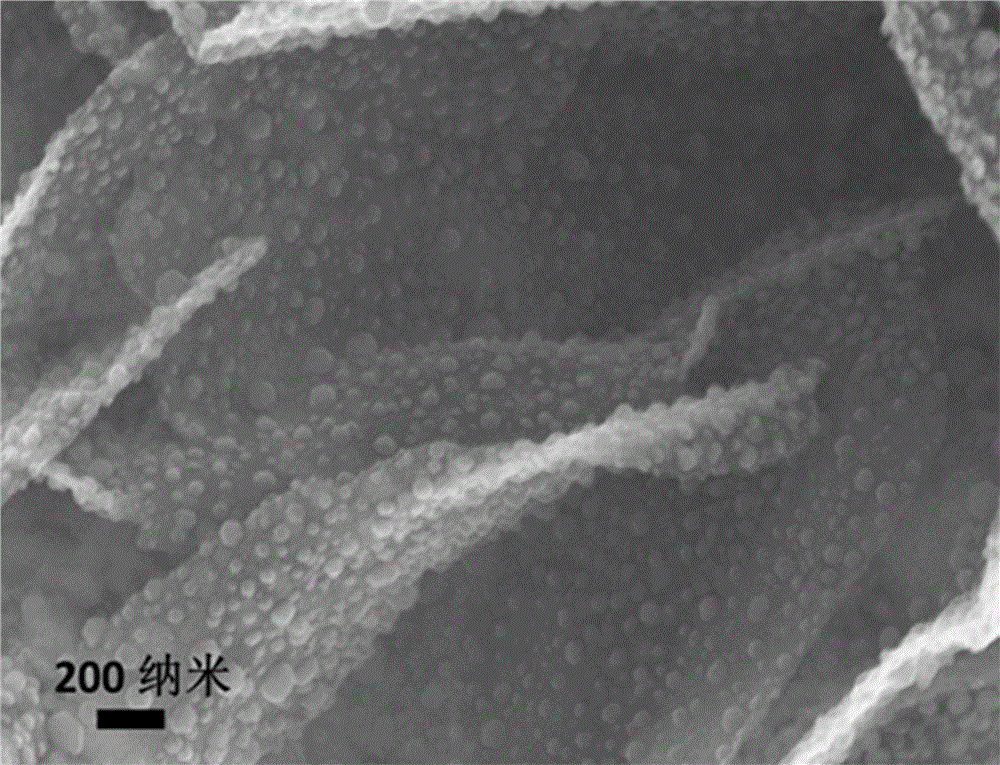

Cobalt sulfide/carbon composite material with flower-like structure and preparation method thereof

A carbon composite material, flower-like structure technology, applied in structural parts, nanotechnology for materials and surface science, electrical components, etc., can solve the problems of complex technology and equipment, high production cost, low production cost, prevent The effect of agglomeration, high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: First, 5 mmol of Co(NO 3 ) 2 ·6H 2 O was mixed with 10 mmol of hexamethylenetetramine and dissolved in 20 mL of de-carbonated deionized water to prepare a mixed solution; then 15 mmol of sulfanilic acid and 15 mmol of NaOH were dissolved in 20 mL of de-carbonated Neutralization reaction was carried out in deionized water to obtain sodium m-aminobenzenesulfonate solution; under the protection of nitrogen, the above mixed solution and sodium m-aminobenzenesulfonate solution were mixed, stirred evenly, and then transferred to a 50 mL polytetrafluoroethylene substrate In a high-pressure reactor, put it in an oven at 100 o C constant temperature reaction for 12 h, take out the autoclave and cool to room temperature naturally, wash with 500 mL of deionized water and 200 mL of ethanol by suction filtration until the pH value of the filtrate is 7, and then filter the cake at 80 o C was air-dried for 8 h to obtain cobalt hydroxide intercalated with m-aminobenzenesu...

Embodiment 2

[0021] Embodiment 2: first the CoCl of 2.5 mmol 2 ·6H 2 O was mixed with 5 mmol of hexamethylenetetramine and dissolved in 20 mL of de-carbonated deionized water to prepare a mixed solution; then 15 mmol of p-aminobenzenesulfonic acid and 15 mmol of NaOH were dissolved in 20 mL of de-carbonated de-carbonated Neutralization reaction was carried out in deionized water to obtain sodium p-aminobenzenesulfonate solution; under the protection of nitrogen, the above mixed solution and sodium p-aminobenzenesulfonate solution were mixed, stirred evenly, and then transferred to a 50 mL polytetrafluoroethylene substrate In a high-pressure reactor, put it in an oven at 100 o C constant temperature reaction 8 h, take out the autoclave and cool to room temperature naturally, use 500 mL of deionized water and 200 mL of ethanol to filter and wash until the pH value of the filtrate is 7, and then filter the cake at 70 o C was air-dried for 12 h to obtain cobalt hydroxide intercalated with p-...

Embodiment 3

[0023] Embodiment 3: first the CoSO of 1 mmol 4 ·7H 2 O was mixed with 2 mmol of hexamethylenetetramine and dissolved in 20 mL of de-carbonated deionized water to prepare a mixed solution; then 15 mmol of m-aminobenzenesulfonic acid and 15 mmol of NaOH were dissolved in 20 mL of de-carbonated Neutralization reaction was carried out in deionized water to obtain sodium m-aminobenzenesulfonate solution; under the protection of nitrogen, the above mixed solution and sodium m-aminobenzenesulfonate solution were mixed, stirred evenly and transferred to a 50 mL polytetrafluoroethylene substrate In a high-pressure reactor, put it in an oven at 120 o C constant temperature reaction for 8 h, take out the autoclave and cool it down to room temperature naturally, filter and wash with 500 mL deionized water and 200 mL ethanol until the pH value of the filtrate is 7, then put the filter cake at 60 o C was air-dried for 20 h to obtain cobalt hydroxide intercalated with m-aminobenzenesulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com