Application and method of neutral phosphamide extraction agent for extracting and separating thorium

A technology of phosphoramide and extractant, which is applied to the extraction and separation of thorium by neutral phosphoramide extractant, and the field of extraction and separation of thorium by neutral phosphoramide extractant, which can solve the problems of low capacity and low reuse rate, and achieve the extraction capacity. Strong, wide application range, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] In order to further illustrate the solution of the present invention, specific examples of the present invention are provided to help those skilled in the art understand and implement the present invention, but the present invention is not limited to these examples.

[0110] Reagents and sources

[0111] Sulfonated kerosene (No. 260 kerosene) was purchased from Luoyang Aoda Chemical Co., Ltd.

[0112] P350, P204, P507, P229 and No. 3 aviation kerosene were purchased from Shanghai Laiyashi Chemical Co., Ltd.

[0113] Cyanex272 and Cyanex923 were purchased from Shanghai Cyanex Chemical Co., Ltd.

[0114] The feed liquid, washing liquid, and stripping agent were self-made in the laboratory, and other reagents (such as acids, etc.) were commercially available analytical reagents.

[0115] Product purity was determined by ICP-OES (instrument model: Optical-8000, manufacturer: Perkin Elmer).

[0116] The nuclear magnetic resonance instrument is Varian Mercury300.

[0117]...

preparation Embodiment 1 2

[0118] Preparation Example 1 The synthesis of diisooctyl-isooctyloxyphosphoramide

[0119]

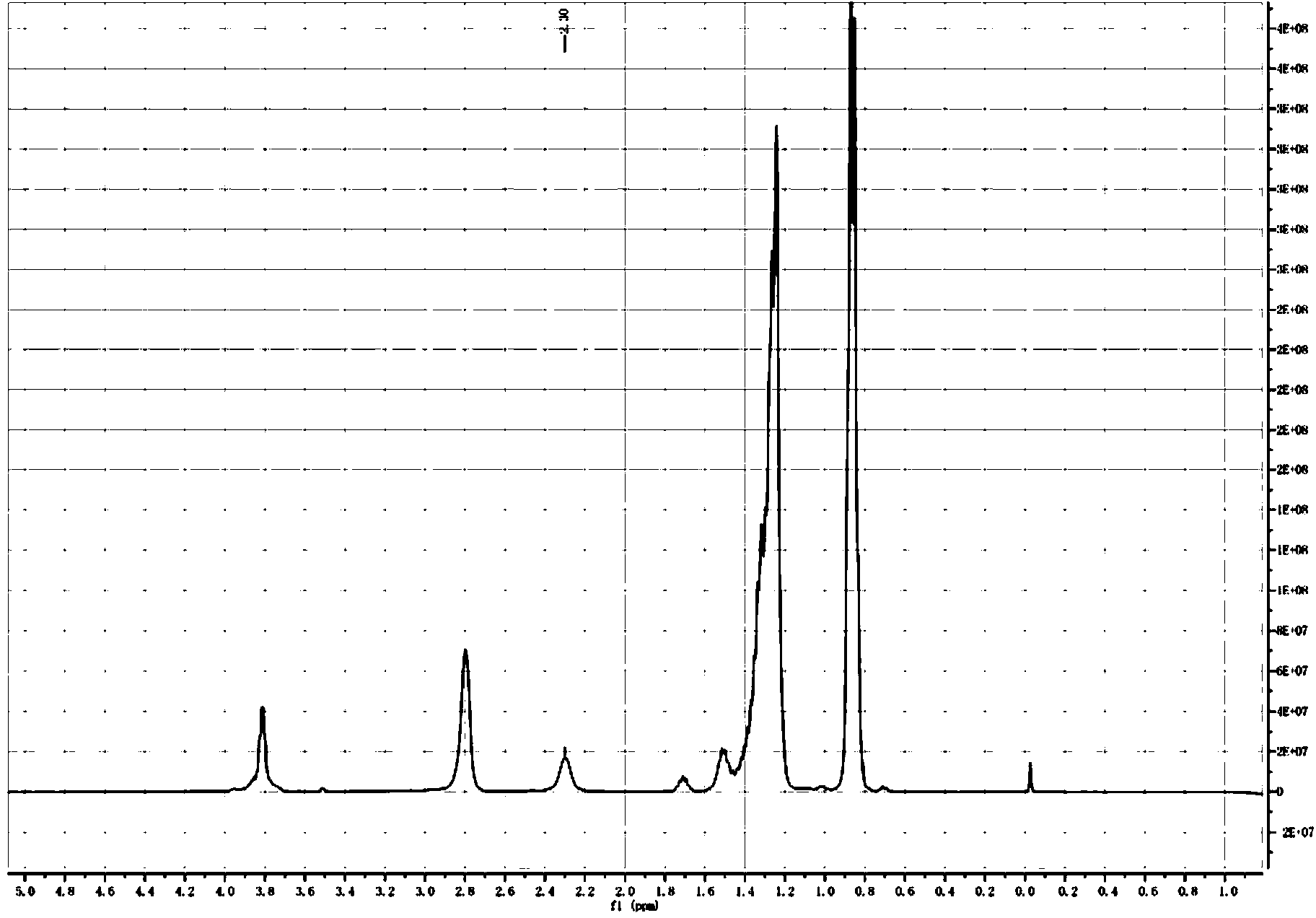

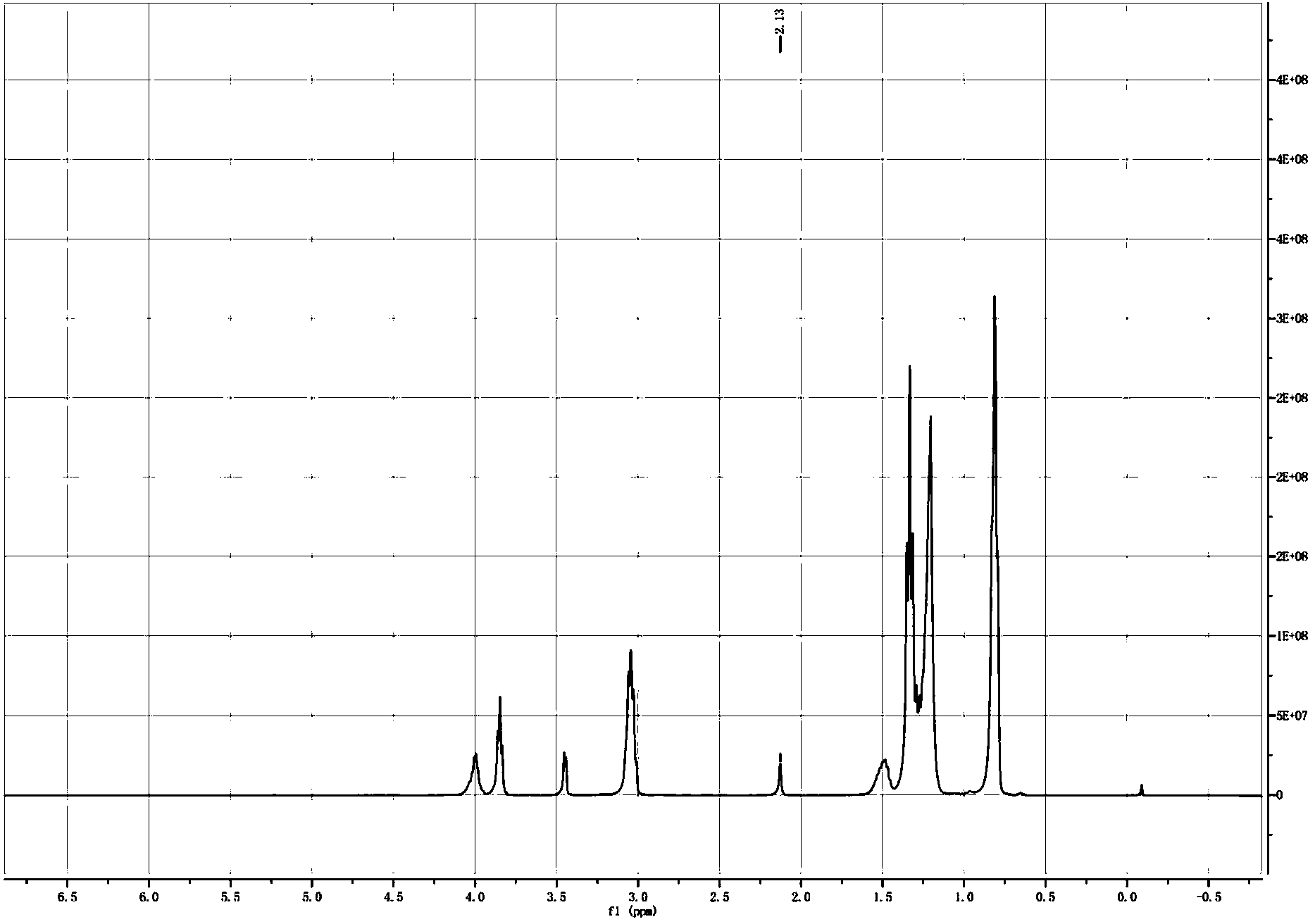

[0120] For the synthesis method of diisooctyl-isooctyloxyphosphoramide, refer to Preparation Example 2 of Chinese Patent Application No. 201410040023.5. 1 H NMR spectrum (in CDCl 3 in) such as figure 1 shown.

preparation Embodiment 2 3

[0121] The synthesis of three (diisobutyl) phosphoramides of preparation example 2

[0122]

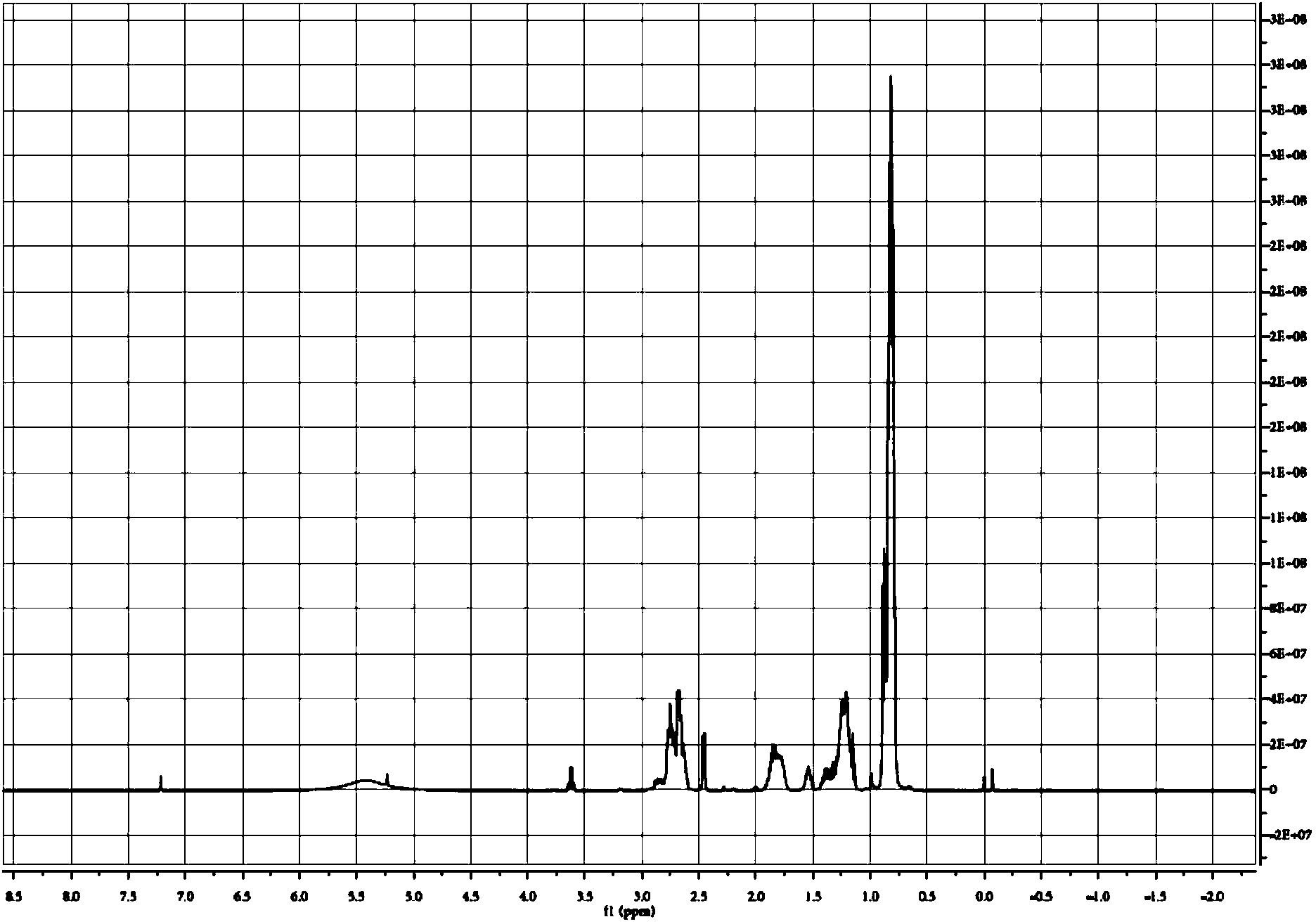

[0123] Take 9.3ml of phosphorus oxychloride, add 100ml of dichloromethane as diluent, slowly add 106ml of diisobutylamine in the ice-salt bath, control the temperature below 5°C during the whole process, after the addition, react for 5 hours, and depressurize The hydrochloric acid gas was pumped out, and the reaction was carried out at room temperature for 12 hours; the obtained reaction product was washed with water until it was nearly neutral, and the dichloromethane was removed by rotary evaporation to obtain the desired tris(diisobutyl)phosphoramide. 1 H NMR spectrum (in CDCl 3 in) such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com