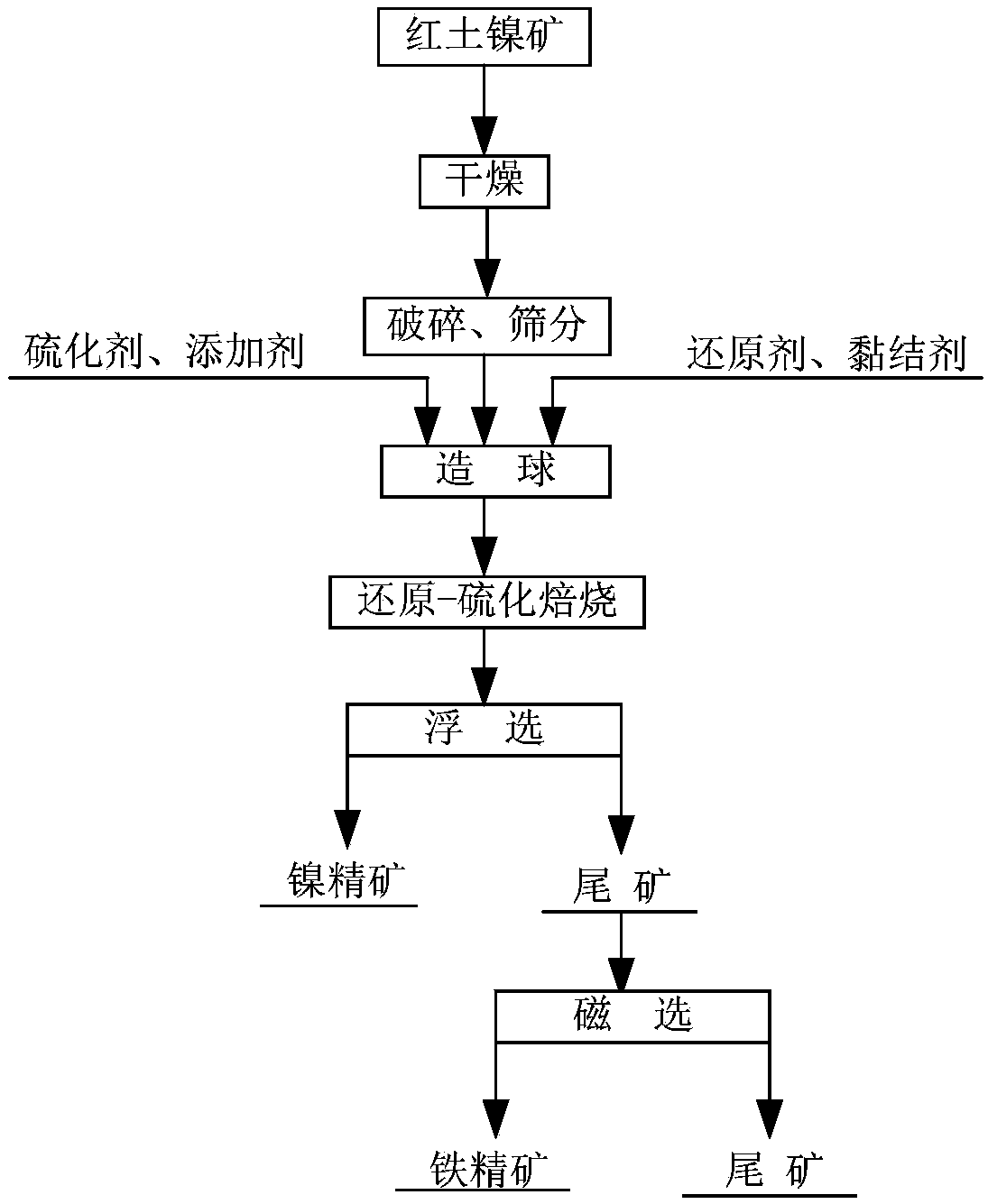

Method of selective sulfidation roasting for laterite nickel ore

A laterite nickel ore, selective technology, applied in chemical instruments and methods, flotation, process efficiency improvement and other directions, can solve the problems of high energy consumption, long process, low energy consumption, etc., achieve low energy consumption, enrichment The effect of large ratio and low roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

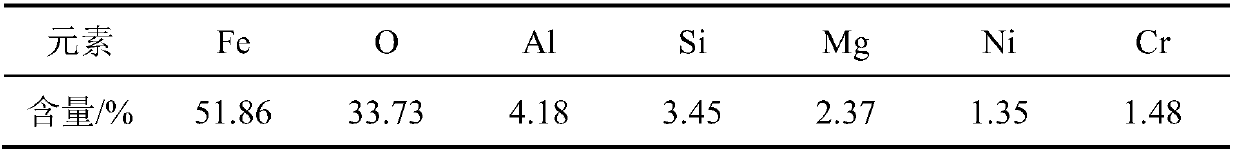

Embodiment 1

[0050] The laterite nickel ore is dried until the moisture content is less than 5%, and after being crushed, passed through a 5mm sieve, mixed with 10% of the mass fraction of sodium carbonate, 7.5% of charcoal, 5% of sulfur, and 3% of CMC to form pellets. The diameter of the pellets is 25-50 mm. The pellets are placed in a self-made rotary kiln, firstly roasted at 400 ° C for 2 h, then heated to 1000 ° C for 1.5 h, and cooled to room temperature under nitrogen protection; the results of phase analysis show that 90 % of nickel exists in the form of sulfide, and more than 85% of iron exists in the form of ferric oxide; the roasted product is finely ground in the mill until the pulp particle size is -74μm, accounting for 80%, and amyl xanthate is used for collection Nickel concentrate can be obtained with 8.3% nickel content and a nickel recovery rate of 78.6% through the flotation of nickel; the flotation tailings can be magnetically separated under a magnetic field strength of ...

Embodiment 2

[0052] The laterite nickel ore is dried until the moisture content is lower than 5%, and after being crushed, passed through a 5mm sieve, mixed with 5% sodium sulfate, 5% coke, 15% sulfur, and 5% bentonite to form pellets. The diameter of the pellets is 25-50mm. The pellets are placed in a self-made rotary kiln, firstly roasted at 400°C for 3h, then heated up to 950°C for 1h, and cooled to room temperature under nitrogen protection; the results of phase analysis show that 95% of the calcined sand The above nickel exists in the form of sulfide, and more than 78% of the iron exists in the form of ferric oxide; the roasted product is finely ground in the mill until the pulp particle size is -74μm, accounting for 75%, and isopropyl xanthate is used as the capture Collector flotation nickel can obtain nickel concentrate with nickel content of 6.8% and nickel recovery rate of 84.3%; the flotation tailings can be magnetically separated under the magnetic field strength of 0.8KGs to ob...

Embodiment 3

[0054] The laterite nickel ore is dried until the moisture content is less than 5%, and after being crushed, passed through a 5mm sieve and mixed with 5% sodium sulfate, 5% sodium carbonate, 10% pulverized coal, 7.5% sulfur, 2.5% The gelatinized starch was mixed evenly to make pellets. The diameter of the pellets was 25-50mm. The pellets were placed in a self-made rotary kiln, firstly roasted at 400°C for 2h, then heated to 950°C for 2h, and cooled to room temperature under nitrogen protection; The analysis results show that more than 92% of the nickel in the roasted product exists in the form of sulfide, and more than 82% of the iron exists in the form of ferric oxide; the roasted product is finely ground in the mill until the pulp particle size is -74μm, accounting for 85% , using isopropyl xanthate as a collector to flotation nickel sulfide, nickel concentrate with a nickel content of 7.8% and a nickel recovery rate of 81.8% can be obtained; the flotation tailings can be mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com