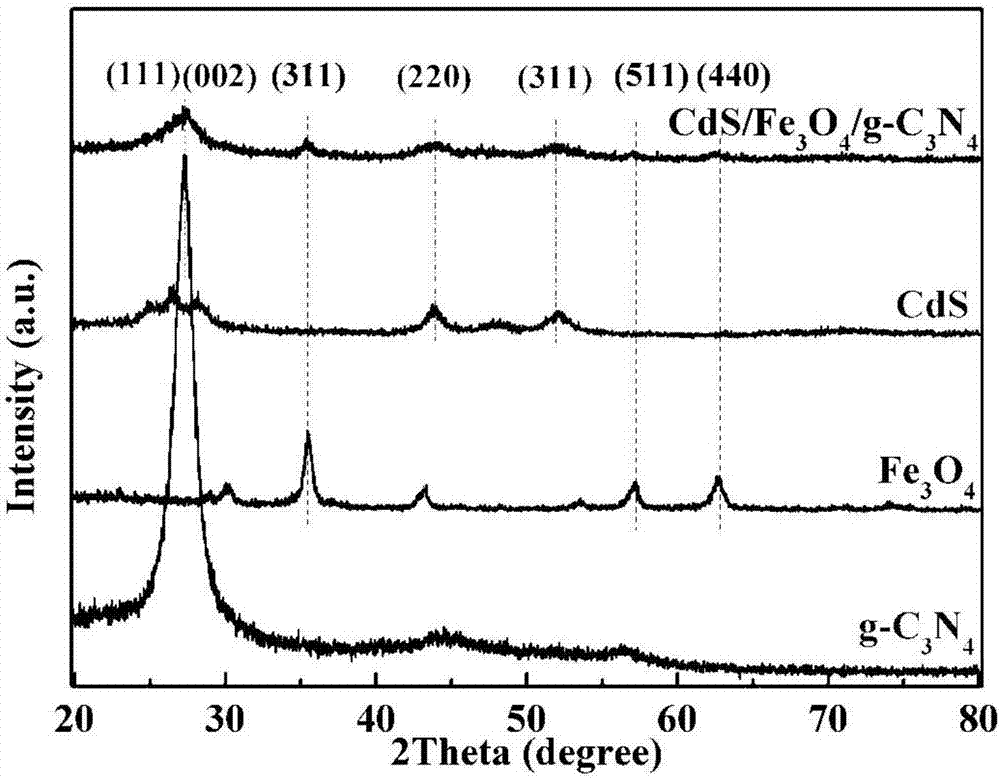

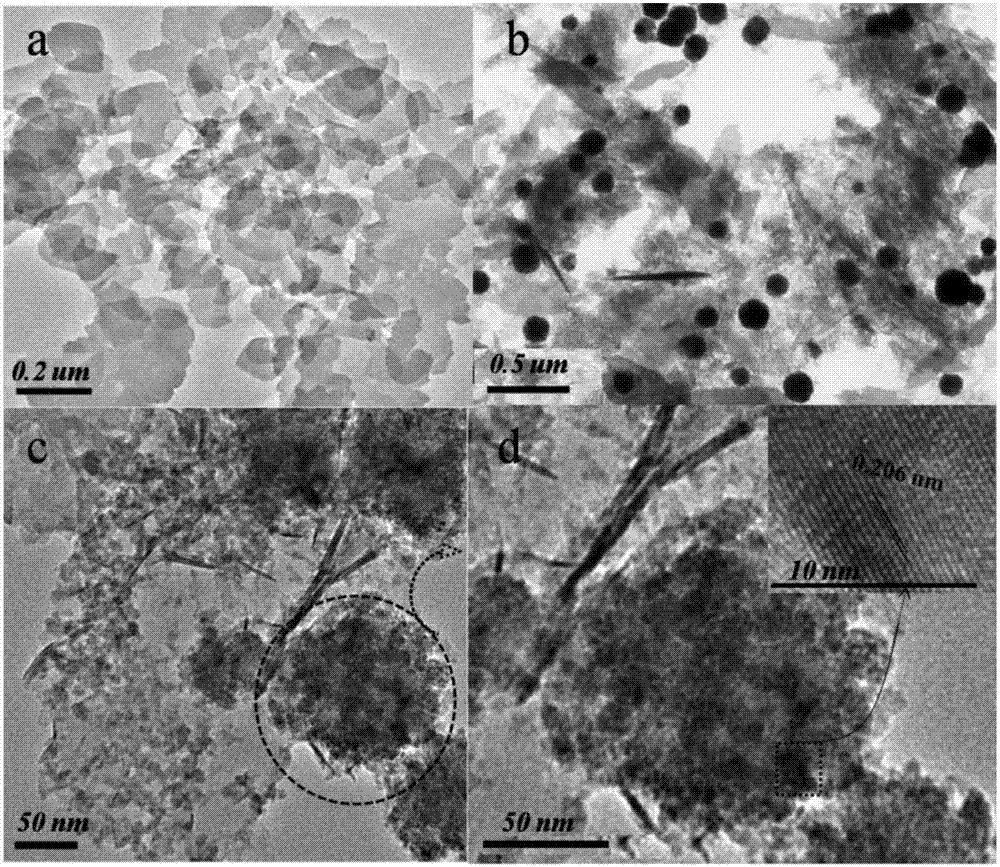

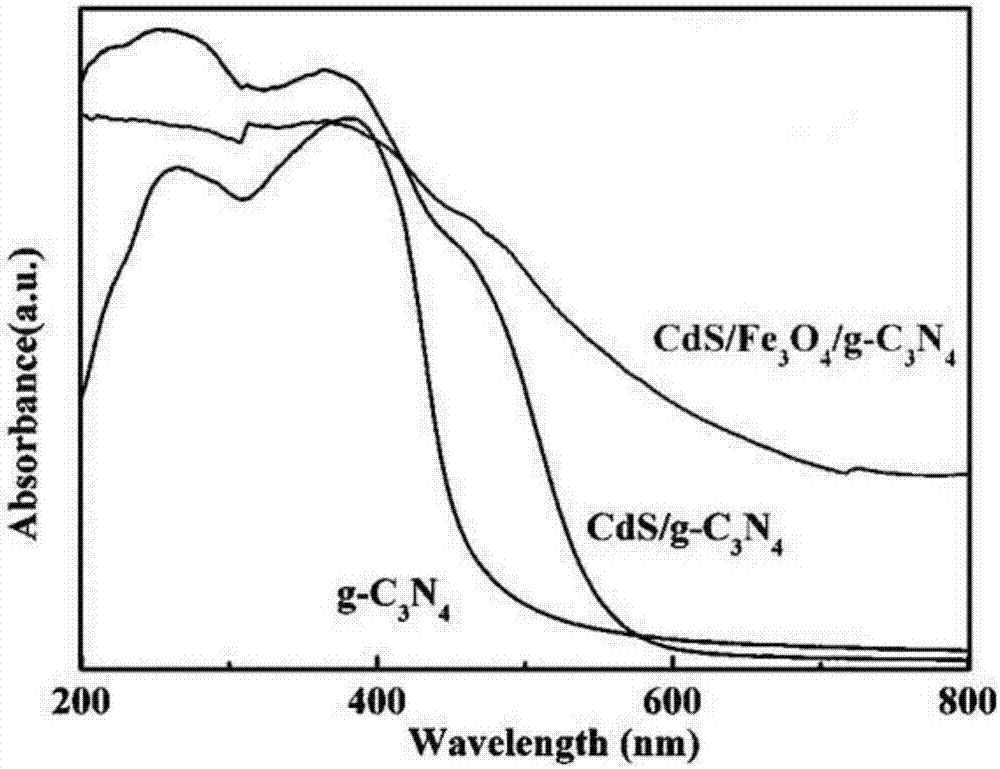

CdS/Fe3O4/C3N4 composite photocatalyst as well as preparation method and use thereof

A composite light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the loss of treatment effect, loss of sensitivity and drug resistance of pathogenic microorganisms Enhancement and other issues, to achieve the effects of good photocatalytic activity and stability, convenient separation and recovery, and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1, g-C 3 N 4 Preparation: Take 3g of purchased melamine, place it in a crucible, and place it in a muffle furnace, and calcine it in an air atmosphere at 2°C min -1 Raise the temperature to 500°C at a constant temperature for 2 hours, continue to raise the temperature to 550°C at the same rate, and keep it at a constant temperature for 2 hours, cool naturally to room temperature and grind finely to obtain g-C 3 N 4 catalyst of light.

[0027] Step 2, prepare Fe 3 o 4 / g -C 3 N 4 : put g-C 3 N 4 Dispersed in ethylene glycol and sonicated to make g-C 3 N 4 suspension; the Fe(NO 3 ) 3 9H 2 O, PVP, PEG, and CH 3 COONa·3H 2 O dissolved in the above g-C respectively 3 N 4 in the suspension; continue to sonicate the above mixture until it is fully dissolved, then transfer the reaction mixture to a 50mL polytetrafluoroethylene reactor for constant temperature and heat reaction for a period of time; finally, the obtained precipitate Fe 3 o 4 / g -C 3 N 4...

Embodiment 2

[0032] In step 1, the calcination method is to maintain a constant temperature at 500°C for 2 hours in the first stage, and the calcination method in the second stage is to maintain a constant temperature at 550°C for 2 hours, and the heating rate is 10°C / min.

[0033] In step 2, the g-C 3 N 4 , ethylene glycol, Fe(NO 3 ) 3 9H 2 O, PVP, PEG, and CH 3 COONa·3H 2 The amount of O used is 2.0g, 30mL, 0.1g, 0.008g, 0.4g, 0.8g in sequence; the temperature of the solvothermal reaction is 220°C, and the reaction time is 10h.

[0034] In step 3, the Fe 3 o 4 / g -C 3 N 4 , cadmium sulfate, thiourea, PVP, and deionized water are used in the order of 0.3g, 2.1g, 0.05-0.2g, 0.09g, and 150mL; the temperature of the solvothermal reaction is 80°C, and the reaction is 3h.

[0035] Step 4, take 0.05g of CdS / Fe in step 3 3 o 4 / g -C 3 N 4 Added to 100mL containing 20mg L -1 In the reactor of tetracycline solution, stir in the dark at 30°C to achieve adsorption equilibrium; turn on...

Embodiment 3

[0037] In step 1, the calcination method is to maintain a constant temperature at 500°C for 2 hours in the first stage, and the calcination method in the second stage is to maintain a constant temperature at 550°C for 2 hours, and the heating rate of the first stage calcination and the second stage calcination are both 6°C / min.

[0038] In step 2, the g-C 3 N 4 , ethylene glycol, Fe(NO 3 ) 3 9H 2 O, PVP, PEG, and CH 3 COONa·3H 2 The amount of O used was 1 g, 20 mL, 0.08 g, 0.006 g, 0.3 g, and 0.4 g in sequence; the temperature of the solvothermal reaction was 200° C., and the reaction time was 12 h.

[0039] In step 3, the Fe 3 o 4 / g -C 3 N 4 , cadmium sulfate, thiourea, PVP, and deionized water are used in the order of 0.2g, 1.5g, 1g, 0.05g, and 80mL; the temperature of the solvothermal reaction is 70°C, and the reaction is 5h.

[0040] Step 4, take 0.05g of CdS / Fe in step 3 3 o 4 / g -C 3 N 4 Added to 100mL containing 20mg L -1 In the reactor of tetracycline so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com