Method of and apparatus for treating chlorine-containing waste

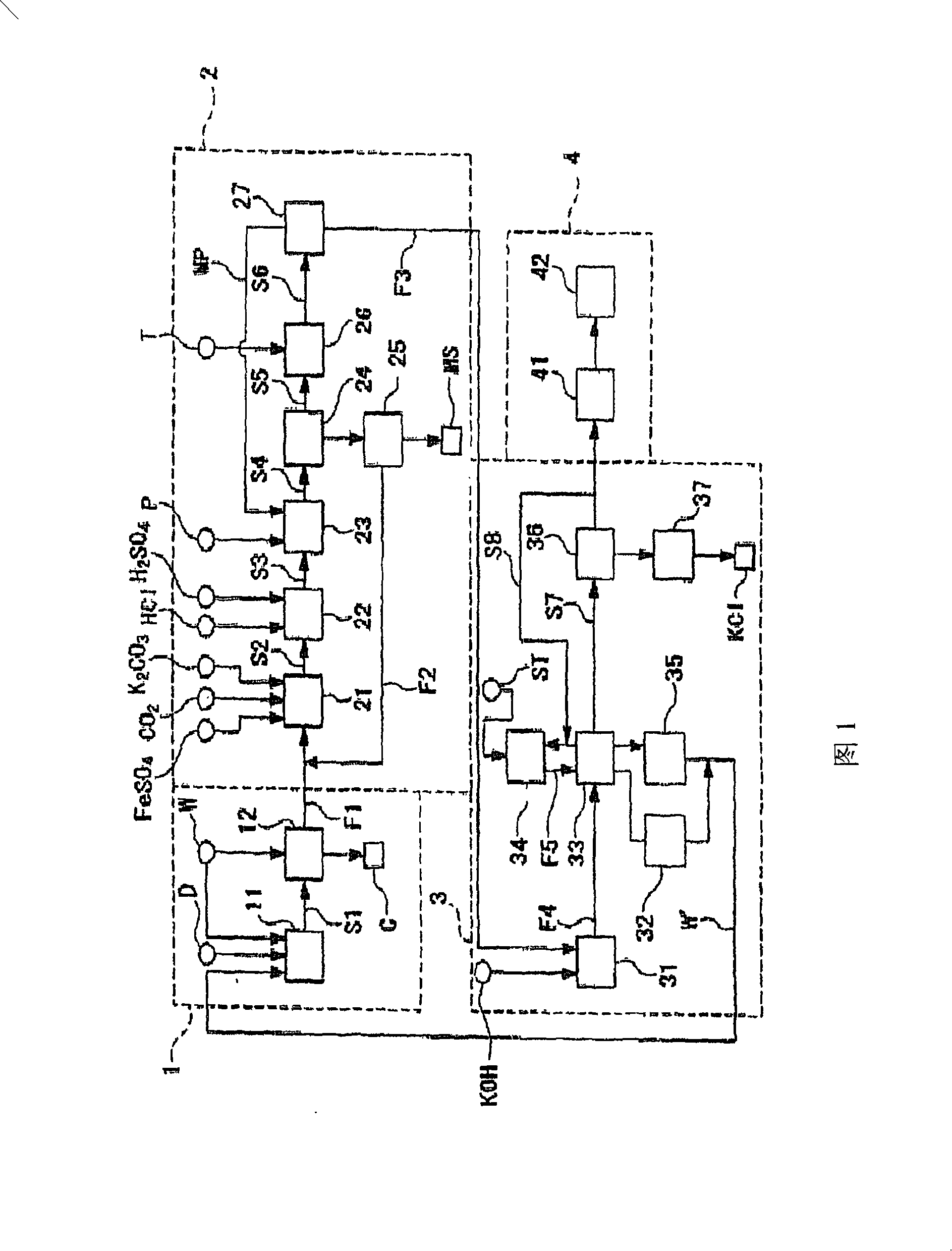

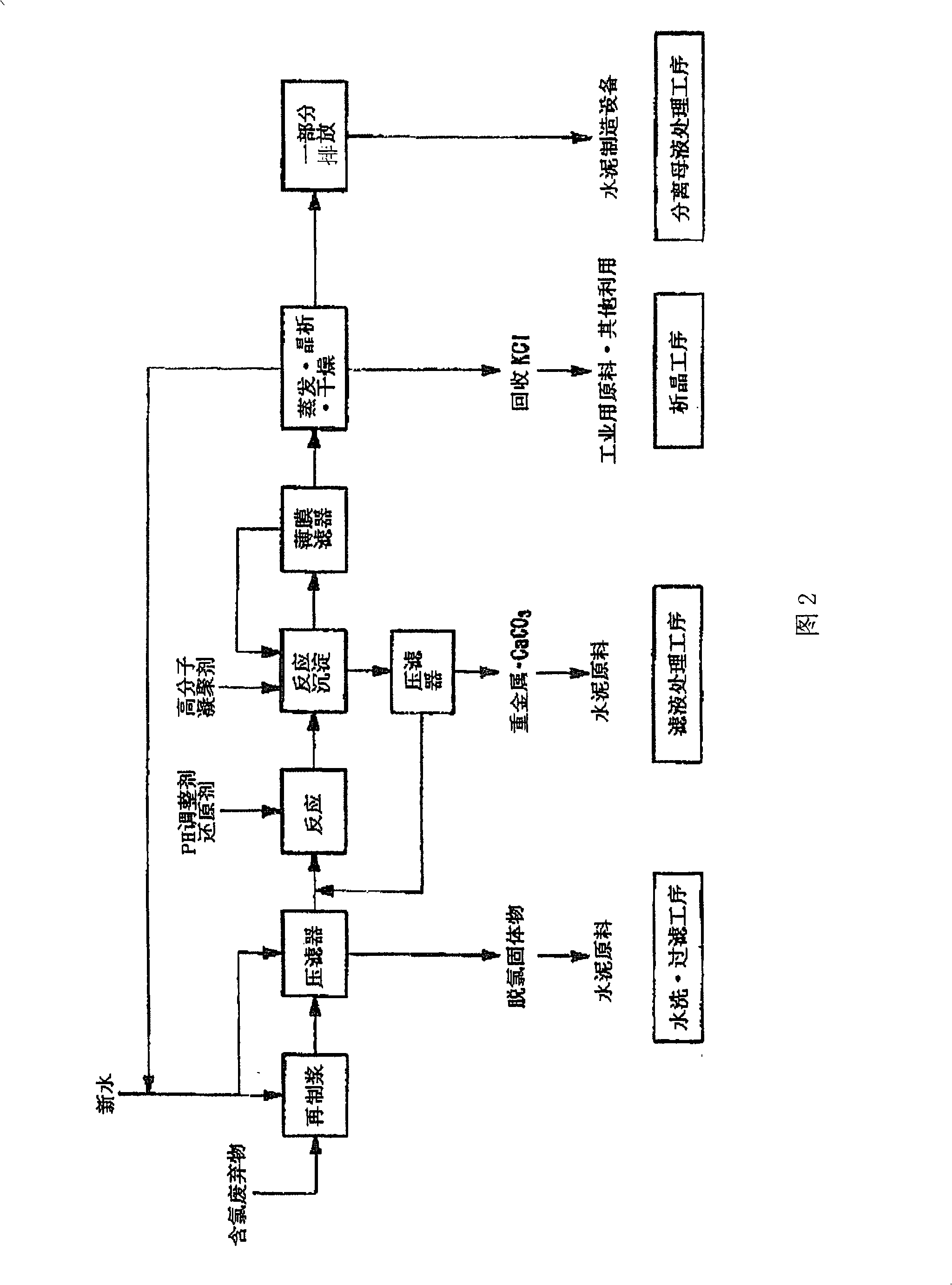

一种处理方法、处理装置的技术,应用在固体废物的清除、分离装置、碱金属氯化物等方向,能够解决大量能源、废弃物处理成本提高、无法获得有效利用高纯度氯化物等问题,达到容易回收、提高纯度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] Hereinafter, the method for treating chlorine-containing waste according to the present invention will be specifically described with examples, but the present invention is not limited to the following examples unless the gist thereof is exceeded.

[0116] In addition, in this Example, the chlorine bypass powder discharged|emitted from a cement kiln and extracted by the chlorine bypass apparatus was used as the powder used as the object of desalination.

[0117] Table 1 shows the composition of this powder.

[0118] Table 1

[0119] project

unit

content

SiO 2

weight%

8.1

Al 2 o 3

weight%

2.5

Fe 2 o 3

weight%

0.8

CaO

weight%

30.9

MgO

weight%

0.7

SO 4

weight%

4.6

Na 2 o

weight%

1.6

K 2 o

weight%

25.7

Cl

weight%

20.8

Cu

mg / Kg

1750

Zn

mg / Kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com