Phase change heat insulation composite hollow building block

A hollow block and thermal insulation composite technology, which is applied to building materials and other directions, can solve the problems of poor thermal performance, reduced thermal resistance of composite blocks, and reduced heat capacity of building exterior walls, and saves the thickness of blocks. , the effect of improving thermal resistance and thermal capacity, and improving thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

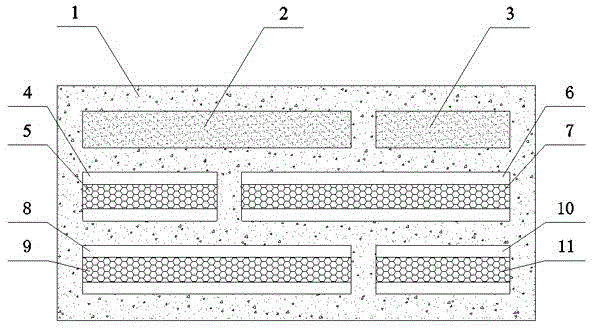

[0026] Such as figure 1As shown, it is a composite hollow block filled with phase change materials and thermal insulation materials, including a block body (1) made of light aggregate concrete, a row of blind holes filled with gypsum-based phase change materials near the indoor side (2 ), (3) and the rest are divided into two rows of through holes (4), (6), (8), (10). The size of the composite hollow block is 390mm×190mm×190mm in length×thickness×height, and the hollow rate is 48.3%-49.0%. The three rows of holes in the block are perpendicular to the thickness direction of the block and are arranged alternately. Each row is composed of a longer hole and a shorter hole. The longer holes in each row are (2), (6) , (8), the shorter holes are (3), (4), (10); the size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com