Thermoplastic resin pellet, process for preparing thermoplastic resin pellets and expanded thermoplastic resin bead

A thermoplastic resin and a manufacturing method technology are applied in the fields of thermoplastic resin particles and their manufacture, and thermoplastic resin expanded particles, which can solve the difficulty of manufacturing resin particles, the inability of tow cutting method to manufacture tiny resin particles, and the ultra-light resin Particles, huge initial investment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

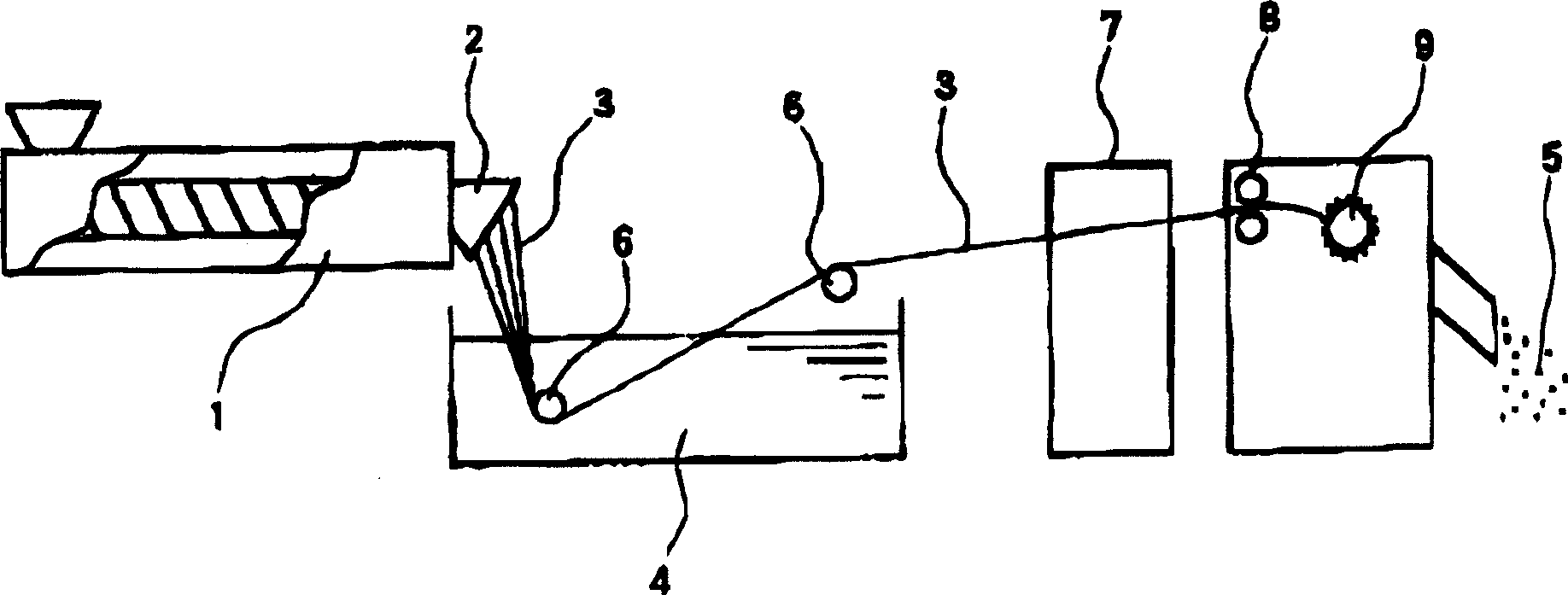

[0080] (Manufacture of resin particles)

[0081] An extruder equipped with a die for forming only the number of circular holes shown in Table 1 at the outlet of the extruder equipped with the screw shown in Table 1, wherein the diameter of the circular holes is as shown in Table 1 was used. 100 parts by weight of propylene-ethylene random copolymer (ethylene component: 2.5% by weight, melting point: 143° C., MFR: 7 g / 10 minutes) and 0.05 parts by weight of zinc borate powder (foam regulator) were supplied to the extruder. It melt-kneaded at 230 degreeC in the extruder. Then, all the holes provided in the die were extruded under the extrusion conditions shown in Table 1 under the atmosphere to form a tow. Next, the tow is immediately introduced into a cooling bath adjusted to 20° C. in a tank with a length of 1 m, a width of 0.4 m, and a depth of 1 m (the cooling bath is accommodated to a tank height of 900 mm) to cool and solidify. , after blowing off the water adhering to t...

Embodiment 8

[0095] (Manufacture of resin particles)

[0096] An extrusion apparatus equipped with a die forming only the number of circular holes shown in Table 3, wherein the diameters of the circular holes are shown in Table 3, was used. To the extruder (screw diameter (barrel diameter): 6.5cm, screw length: 240cm), 100 wt. part and 0.05 part by weight of zinc borate powder (air bubble regulator) were melt-kneaded at 230° C. in the above-mentioned extruder. Then, all the holes provided in the die (shown in Table 3) were extruded under the extrusion conditions shown in Table 1 under the atmosphere to form tows. Next, each tow is immediately introduced into a cooling bath adjusted to 20° C. in a first tank with a length of 1 m, a width of 0.4 m, and a depth of 1 m (the cooling bath is accommodated until the height of the tank is 900 mm) to cool and solidify, and the tow is lifted from the cooling bath. , and then introduced into a washing bath adjusted to 15° C. in a second tank with a ...

Embodiment 9

[0102] 100 parts by weight of the same propylene-ethylene random copolymer as in Example 8, 0.05 parts by weight of zinc borate powder (air bubble regulator), and 1 part by weight of carbon black (coloring agent) were supplied to the extruder approximately the same as in Example 8. , brominated flame retardant (manufactured by Teijin Chemicals Co., Ltd., trade name: ファイヤガ-ド FG-3100) 3 parts by weight, antimony trioxide (flame retardant auxiliary agent) 1.5 parts by weight, in the above extruder at 220 ° C Melt kneading. Except for that, resin particles were produced substantially in the same manner as in Example 8. In addition, expanded particles were produced in substantially the same manner as in Example 8 using the obtained resin particles. In Example 8 and Example 9, there are differences as shown in Table 3 in terms of the number of holes, the ejection amount M per hole, and the amount of dry ice added. Table 3 shows the results. The obtained expanded particles were ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com