Light-emitting component and manufacturing method thereof

A technology for a light-emitting element and a manufacturing method, which is applied to electrical components, semiconductor devices, circuits, etc., can solve the problems of difficulty in improving the luminous efficiency of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

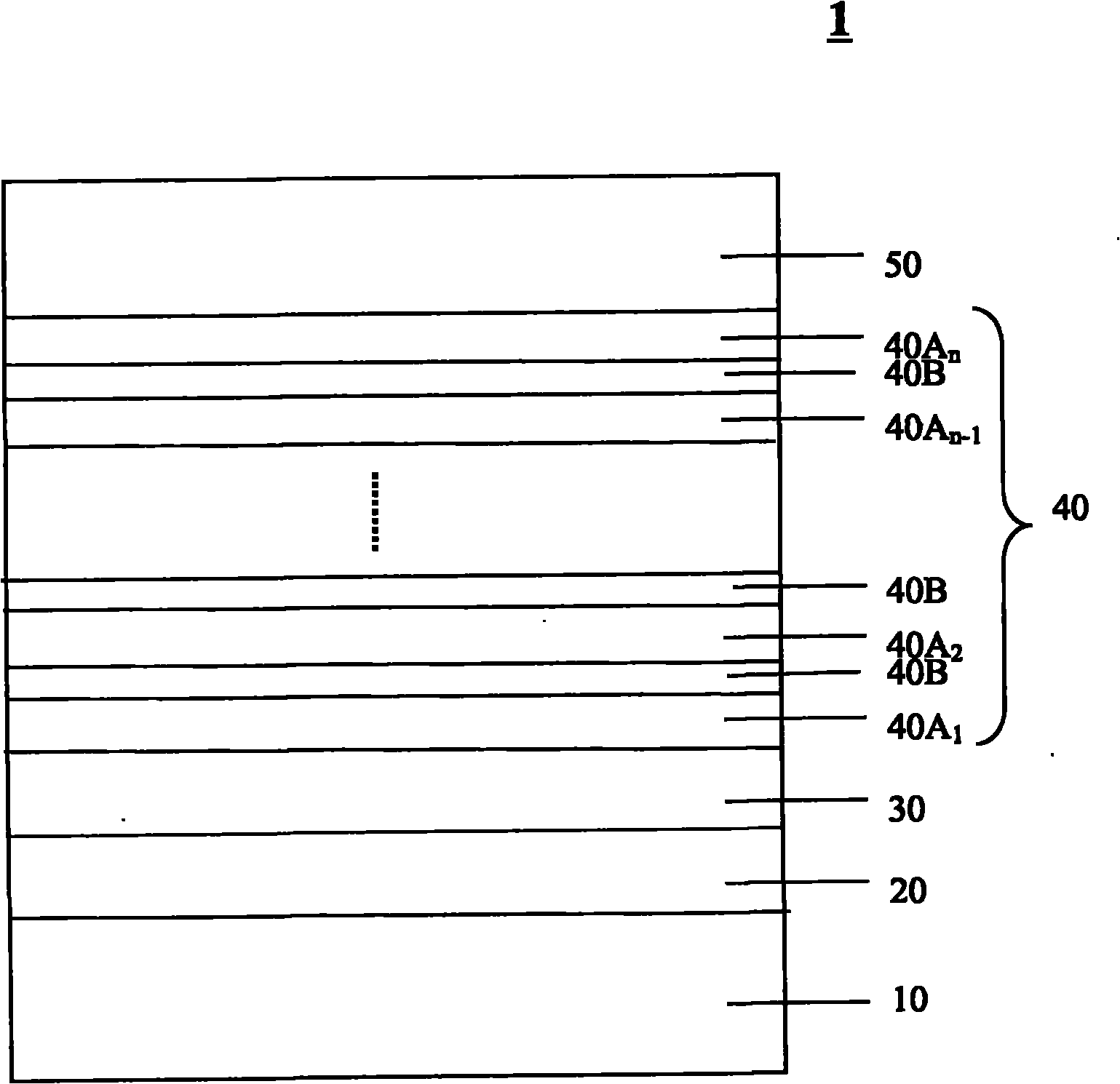

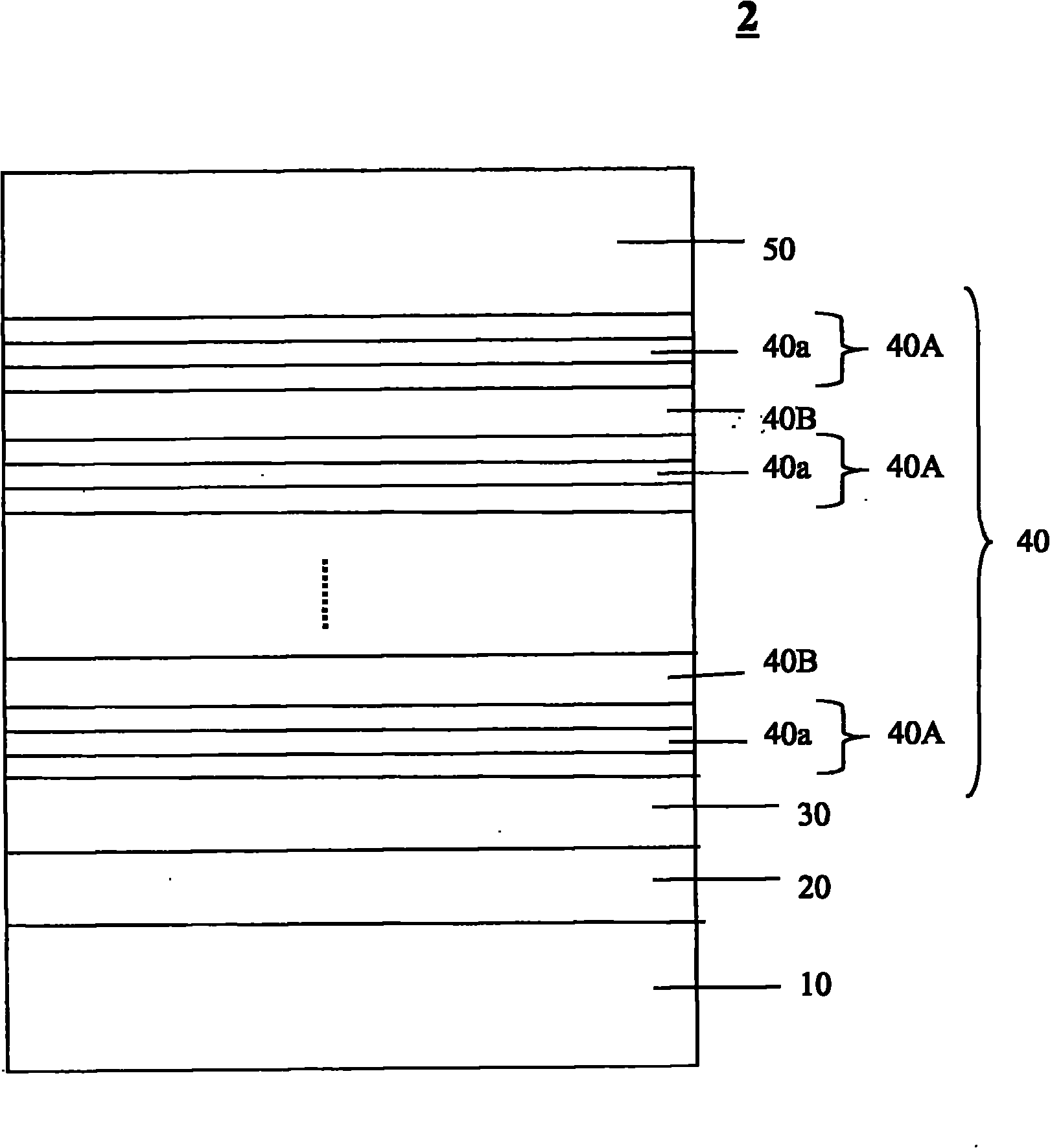

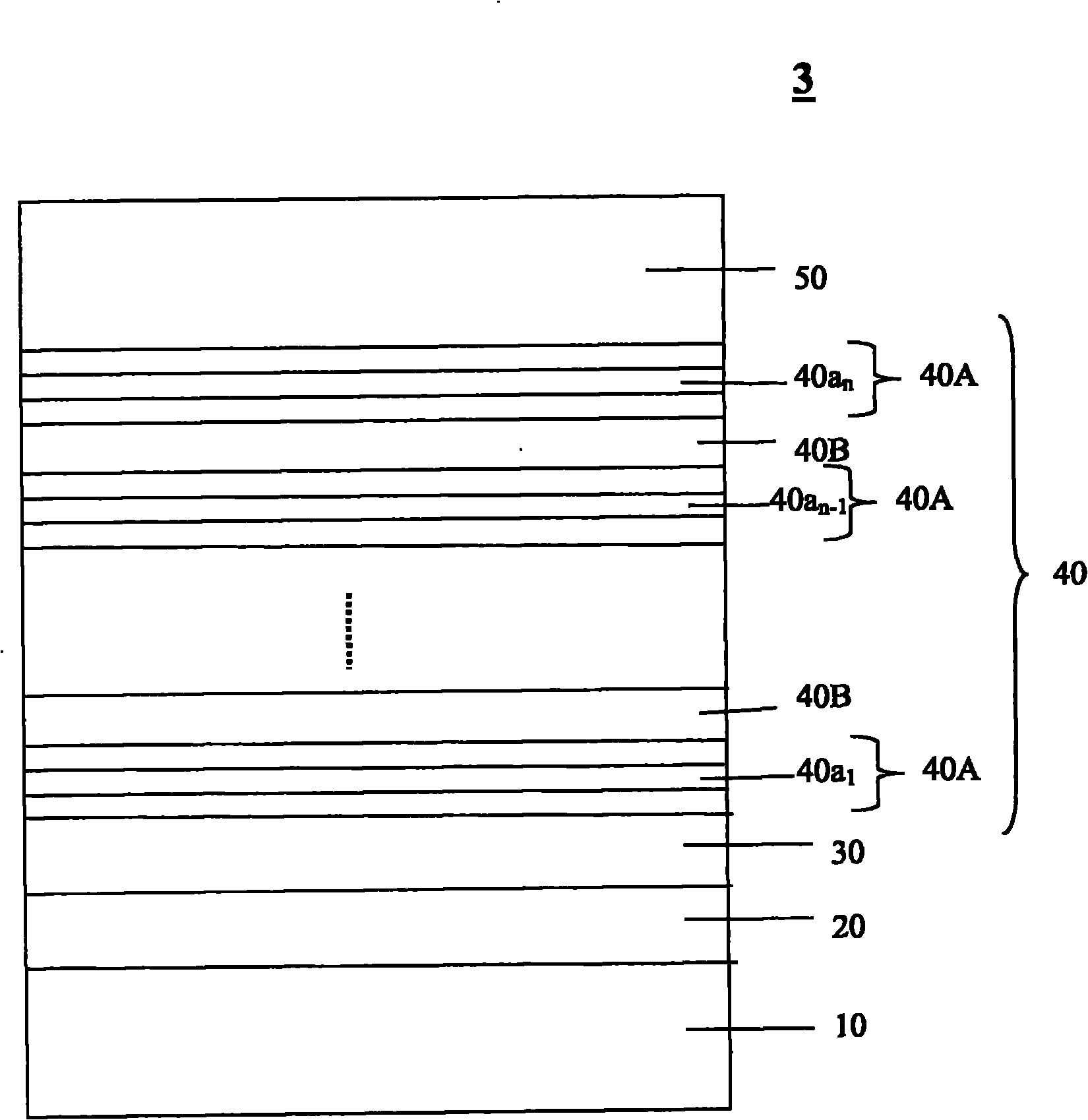

[0025] The first embodiment of the present invention discloses a light emitting device including an active layer. Its active layer is a multiple quantum well structure formed by stacking multiple barrier layers and multiple well layers alternately, in which the barrier layer is doped with p-type impurities to increase the number of holes, and the closer to the potential of the n-type bound layer The lower the doping concentration of the barrier layer, the higher the doping concentration of the barrier layer closer to the p-type bound layer, so as to form a barrier layer structure with a gradual doping concentration. In order to make the narration of this embodiment more detailed and complete, it can cooperate with figure 1 For the drawings, refer to the following description.

[0026] figure 1 A first embodiment of the epitaxial structure of the light-emitting element according to the present invention is disclosed. The epitaxial structure 1 includes a growth substrate 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com