Ultra-fine denier polyurethane filament

A technology of polyurethane and ultra-fine denier, which is applied in the direction of conjugated synthetic polymer artificial filament, filament/thread forming, textile and papermaking, etc. It can solve the problems of large single filament fineness and large viscoelasticity, and achieve good mechanical strength , It is conducive to the improvement of spinning speed and the effect of increasing the number of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

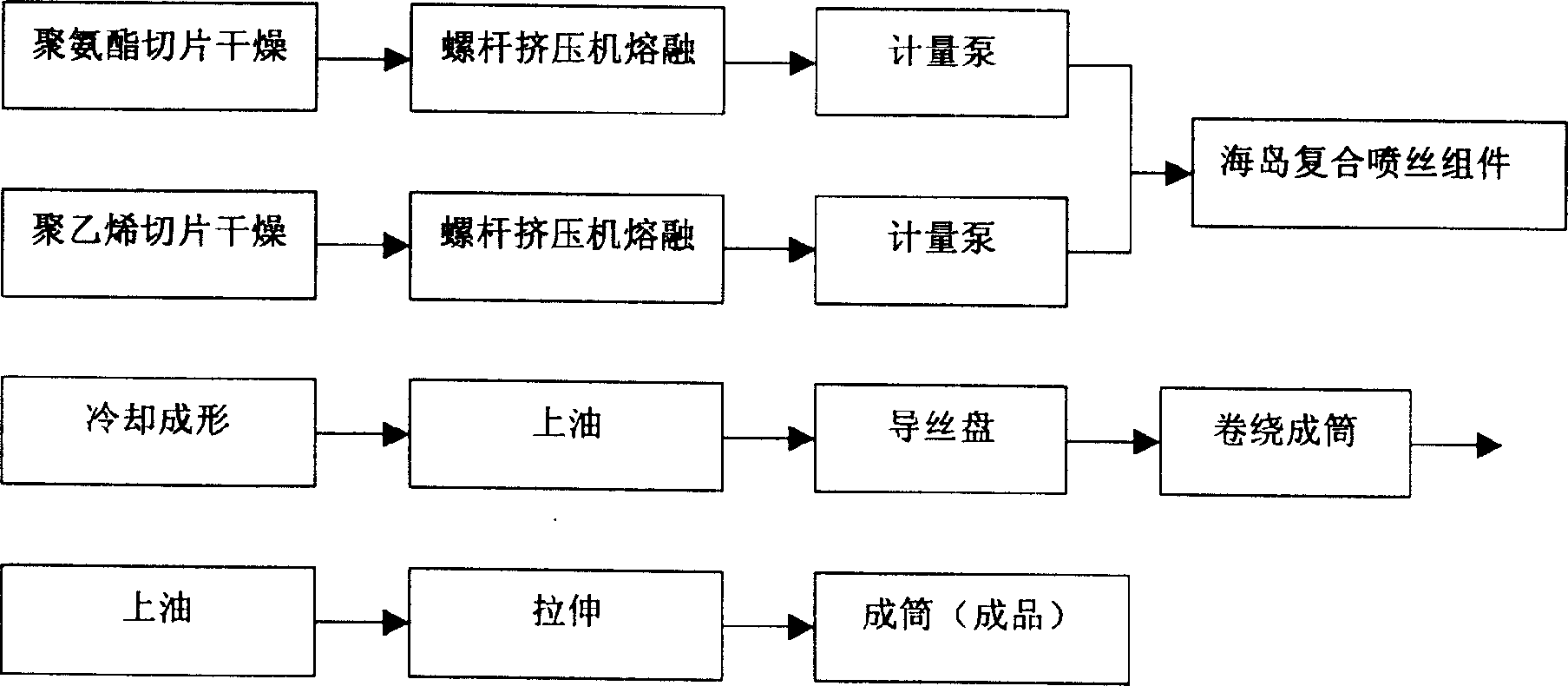

Method used

Image

Examples

Embodiment 1

[0061] TPU / LDPE(MI=50) spinning process

[0062] TPU pump supply 13.5g / min, melt spinning temperature 180-245°C, screw speed 12rep / min, screw pressure 70kg / cm 3 .

[0063] LDPE pump supply is 9.6g / min, melt spinning temperature is 150-245°C, screw speed is 21-22rep / min, screw pressure is 52-62kg / cm 2 .

[0064] The spinning speed is 300m / min. After the spinning is normal, continue to increase the spinning speed to 800m / min to wind smoothly. When the spinning speed is increased to 900m / min, fluff appears, so the spinning speed should be controlled below 800m / min.

[0065] The above-mentioned winding yarn with a spinning speed of 300m / min, stretched 3 times, the fiber breaking strength is 1.75CN / dtex, and the elongation at break is 115.3%, stretched 5 times, the fiber breaking strength is 1.94CN / dtex, and the breaking elongation is 1.94CN / dtex. The rate is 88.5%.

Embodiment 2

[0067] TPU / LDPE(MI=50) spinning process

[0068] The TPU pump supply is 13.5g / min, the melt spinning temperature is 180-235°C, the screw speed is 12rep / min, and the screw pressure is 97kg / cm 3 .

[0069] LDPE pump supply is 11.5g / min, melt spinning temperature is 160-235°C, screw speed is 29rep / min, screw pressure is 60kg / cm 2 .

[0070] The above process stretches 3.7 times, the fiber breaking strength is 1.2CN / dtex, and the breaking elongation is 134.8%.

Embodiment 3

[0072] TPU / LDPE (MI=38) spinning process

[0073] The TPU pump supply is 13g / min, the melt spinning temperature is 190-245°C, the screw speed is 12-13rep / min, and the screw pressure is 67kg / cm 3 .

[0074] The LDPE pump supply rate is 8.5g / min, the melt spinning temperature is 190-275°C, the screw speed is 29rep / min, the obtained fiber is stretched 3.3 times, the filament fiber density is 154dtex, the fiber breaking strength is 2.09CN / dtex, and the breaking elongation The elongation rate is 126.6%, the TPU content of the fiber is 60%, the fiber breaking strength is high, and the breaking elongation is relatively large. After the filament was extracted with toluene, the fineness of the filament was 0.3 dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com