Method for extracting fulvic acid salt from photocatalyst activated lignite

A photocatalyst and fulvic acid technology, applied in the field of coal chemical industry, can solve the problems of difficulty in large-scale industrial production, unfavorable promotion and use, and high resin cost, and achieve the effects of large-scale promotion and application, excellent ultraviolet absorption, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

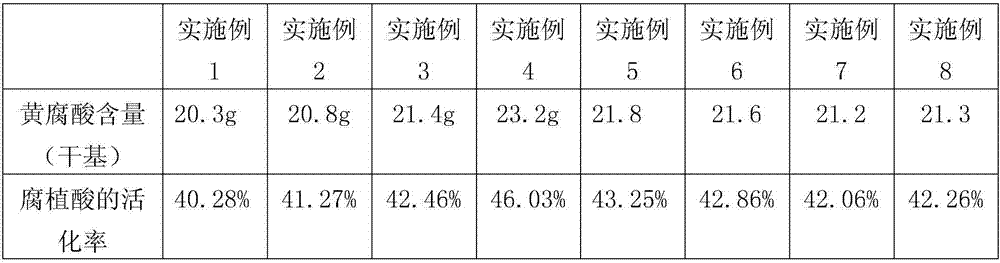

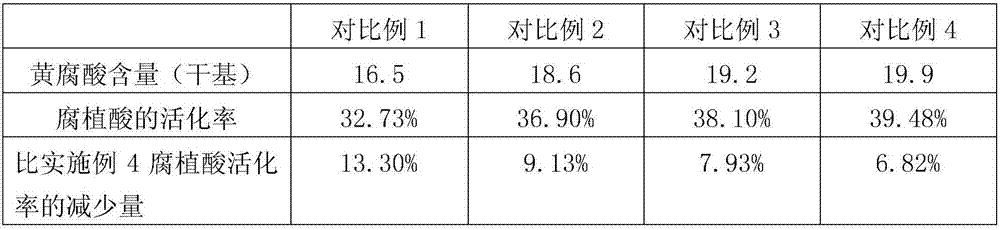

Examples

Embodiment 1

[0035] A method for photocatalyst activating lignite to extract fulvic acid salts, comprising steps:

[0036] Grind 100g lignite into lignite powder with a particle size of 30 mesh, add it to 300g water, then add sodium hydroxide to adjust the pH to 10, react at a temperature of 80°C for 2 hours, and take the upper layer solution after centrifugation to obtain humate solution;

[0037] In above-mentioned humate solution, adding mass concentration is 100g of peracetic acid aqueous solution of 40%, adds 0.8g mean particle diameter simultaneously and is the TiO of 5nm 2, under the condition of ultraviolet light irradiation with a wavelength of 365nm (after each continuous irradiation for 8 minutes, stop the irradiation for 1.5 minutes in the middle), after stirring and reacting at room temperature for 4 hours, add sodium hydroxide to the solution to adjust the pH to 8-9, and then separate the solid and liquid , take the solution and evaporate to dryness to obtain the solid A of ...

Embodiment 2

[0039] A method for photocatalyst activating lignite to extract fulvic acid salts, comprising steps:

[0040] Grind 100g lignite into lignite powder with a particle size of 60 mesh, add it to 500g water, then add potassium hydroxide to adjust the pH to 11, react at a temperature of 50°C for 3 hours, and take the upper layer solution after centrifugation to obtain a humate solution ;

[0041] In above-mentioned humate solution, adding mass concentration is 200g of peracetic acid aqueous solution of 40%, adds 0.1g mean particle diameter simultaneously and is the TiO of 100nm 2 , under the condition of ultraviolet light irradiation with a wavelength of 254nm (after every 10 minutes of continuous irradiation, stop the irradiation for 3 minutes in the middle), after stirring and reacting at room temperature for 4 hours, add potassium hydroxide to the solution to adjust the pH to 8-9, and then separate the solid and liquid. Take the solution and evaporate to dryness to obtain the s...

Embodiment 3

[0043] A method for photocatalyst activating lignite to extract fulvic acid salts, comprising steps:

[0044] Grind 100g lignite into lignite powder with a particle size of 45 mesh, add it to 400g water, then add potassium hydroxide to adjust the pH to 11, react at a temperature of 65°C for 3 hours, and take the upper layer solution after centrifugation to obtain a humate solution ;

[0045] In above-mentioned humate solution, adding mass concentration is 200g of peracetic acid aqueous solution of 40%, adding 0.4g mean particle diameter simultaneously is the TiO2 of 60nm 2 , under the condition of ultraviolet light irradiation with a wavelength of 365nm (after each continuous irradiation for 5 minutes, stop the irradiation for 1 minute in the middle), after stirring and reacting at room temperature for 4 hours, add potassium hydroxide to the solution to adjust the pH to 8-9, and then separate the solid and liquid. Take the solution and evaporate to dryness to obtain the solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com