Method of manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problem of short carrier life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

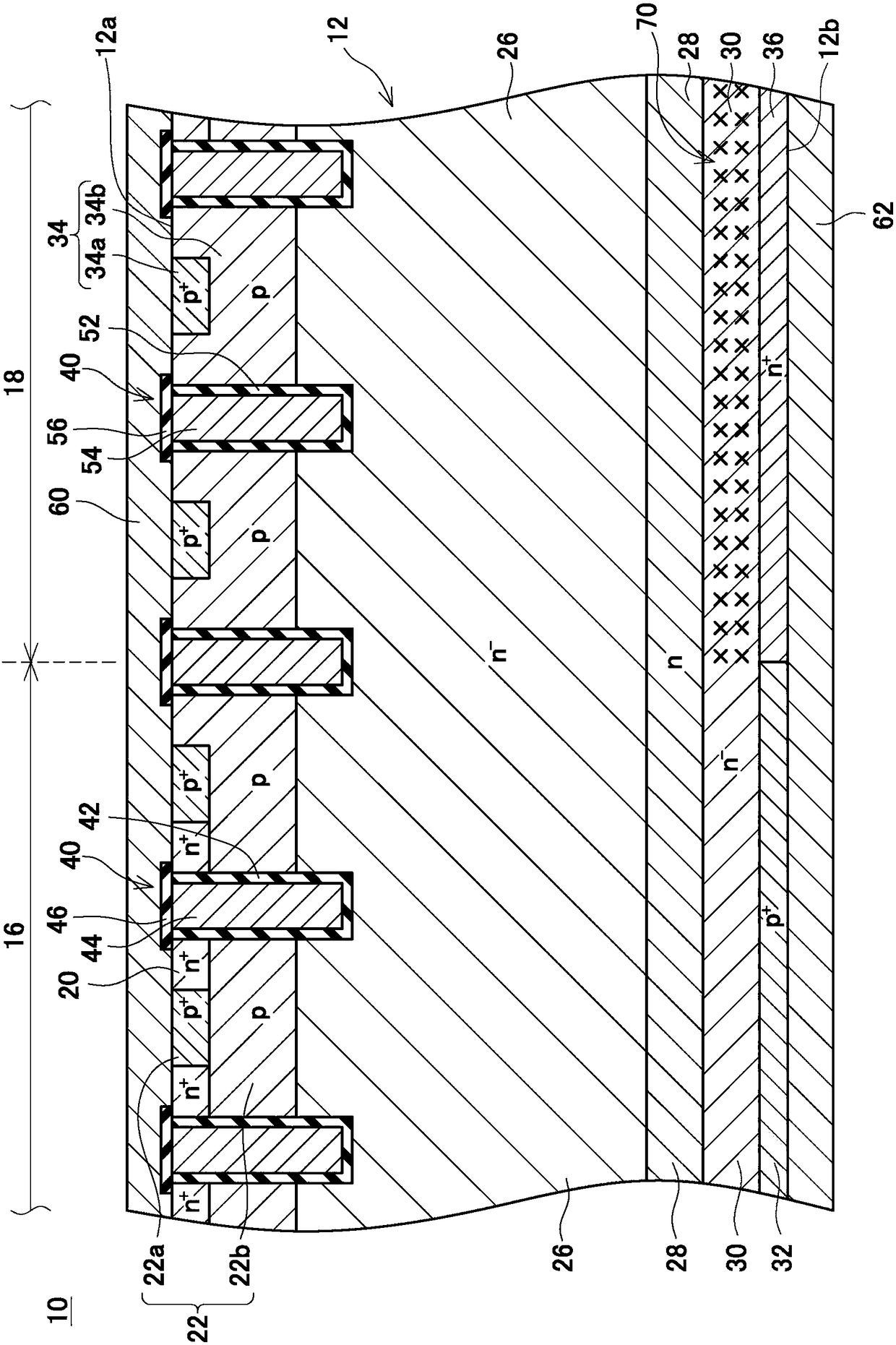

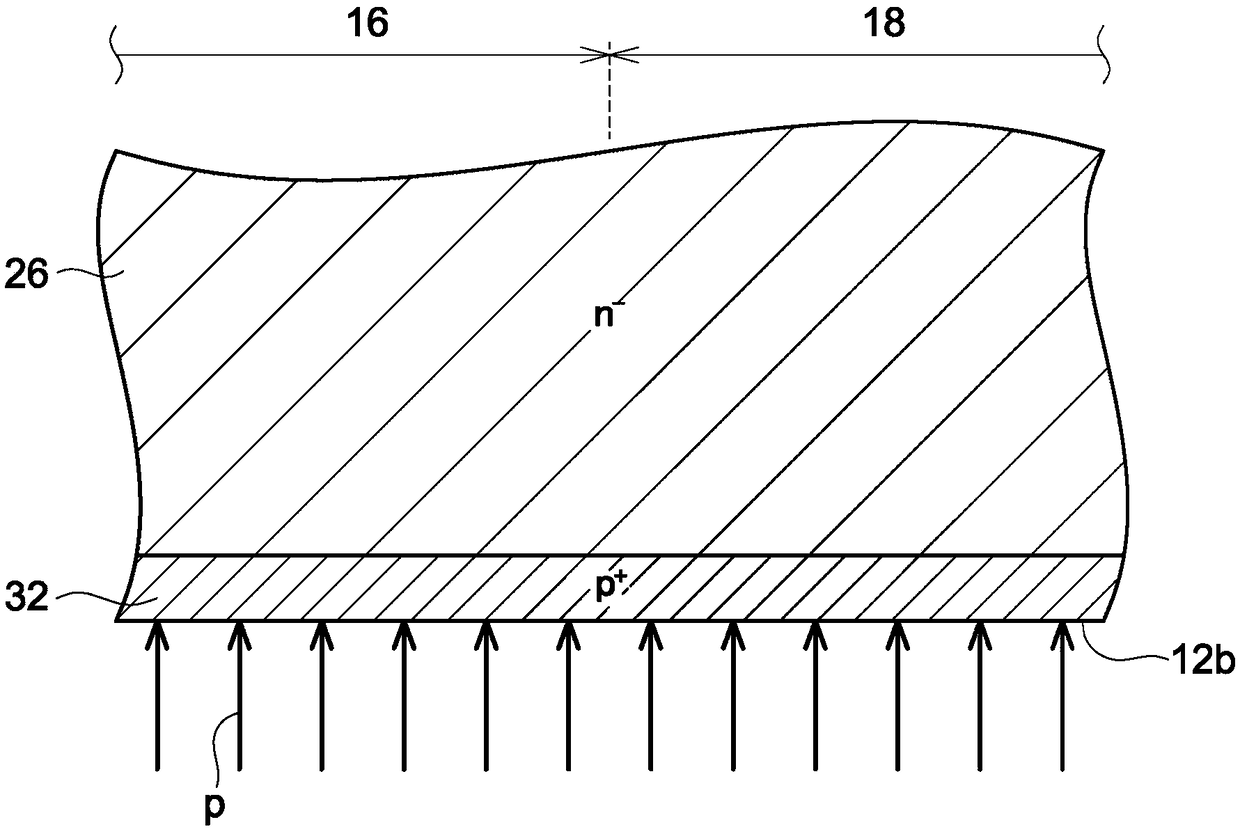

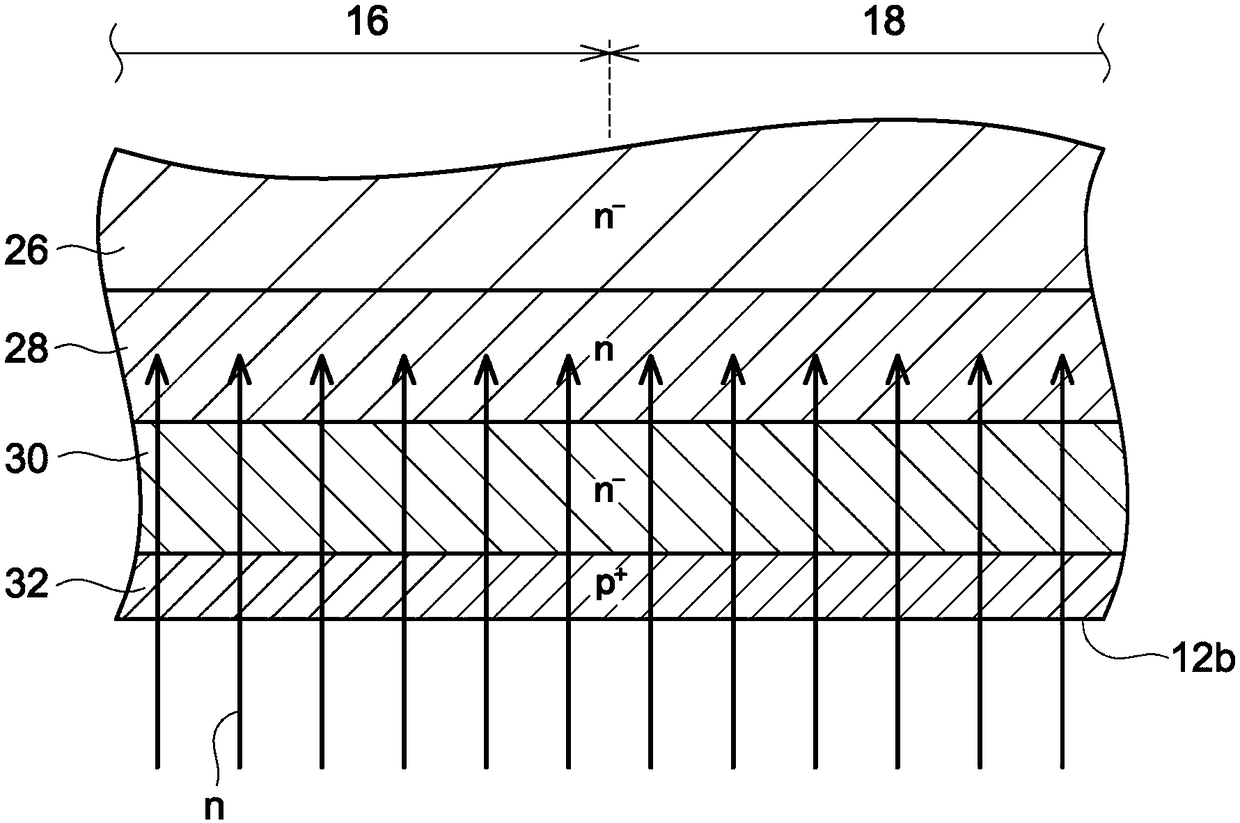

[0020] figure 1 A semiconductor device 10 manufactured by the method of this embodiment is shown. The semiconductor device 10 is composed of a semiconductor substrate 12 , electrodes, insulators, and the like provided on the upper surface 12 a and the lower surface 12 b of the semiconductor substrate 12 . The semiconductor substrate 12 is made of silicon. The semiconductor substrate 12 includes an IGBT region 16 and a diode region 18 . The IGBT region 16 is adjacent to the diode region 18 when the semiconductor substrate 12 is viewed planarly along the thickness direction of the semiconductor substrate 12 . IGBTs are provided in the IGBT region 16 , and diodes are provided in the diode region 18 . That is, the semiconductor device 10 is a so-called RC-IGBT.

[0021] A plurality of grooves 40 are provided on the upper surface 12 a of the semiconductor substrate 12 . Each groove 40 is along with figure 1 The directions perpendicular to the paper surface extend parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com