Three-dimensional porous graphene-based electrochemical electrode material, preparation and application thereof

A three-dimensional porous, electrode material technology, applied in the field of electrochemistry, can solve problems such as overlapping, agglomeration, and affecting the repeatability and stability of sensors, and achieve the effects of good repeatability, inhibition of agglomeration, and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

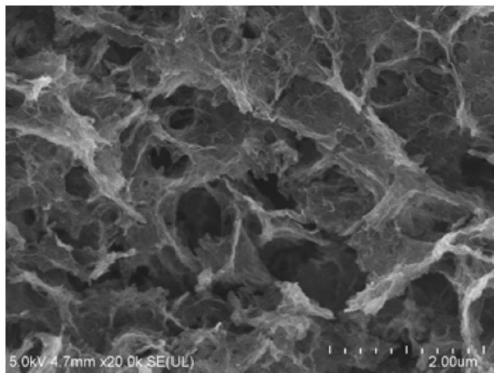

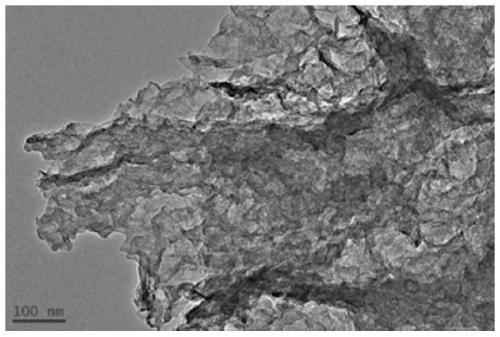

[0034] Adopt hydrothermal method to prepare three-dimensional porous graphene material, concrete steps are: get 10mL graphene oxide (2mg / mL) aqueous solution, add 1mL hydrogen peroxide solution (0.75wt.%), ultrasonic treatment 10min, then graphene oxide and The mixed solution of hydrogen peroxide was transferred to a high-pressure reactor and reacted at a high temperature of 180°C for 4 hours. The resulting product was immersed in ultrapure water and washed for 2 days to remove excess hydrogen peroxide impurities, and then quickly frozen in liquid nitrogen and placed in a Freeze-drying was continued for 12 hours in a freeze-dryer to obtain a solid three-dimensional porous graphene material.

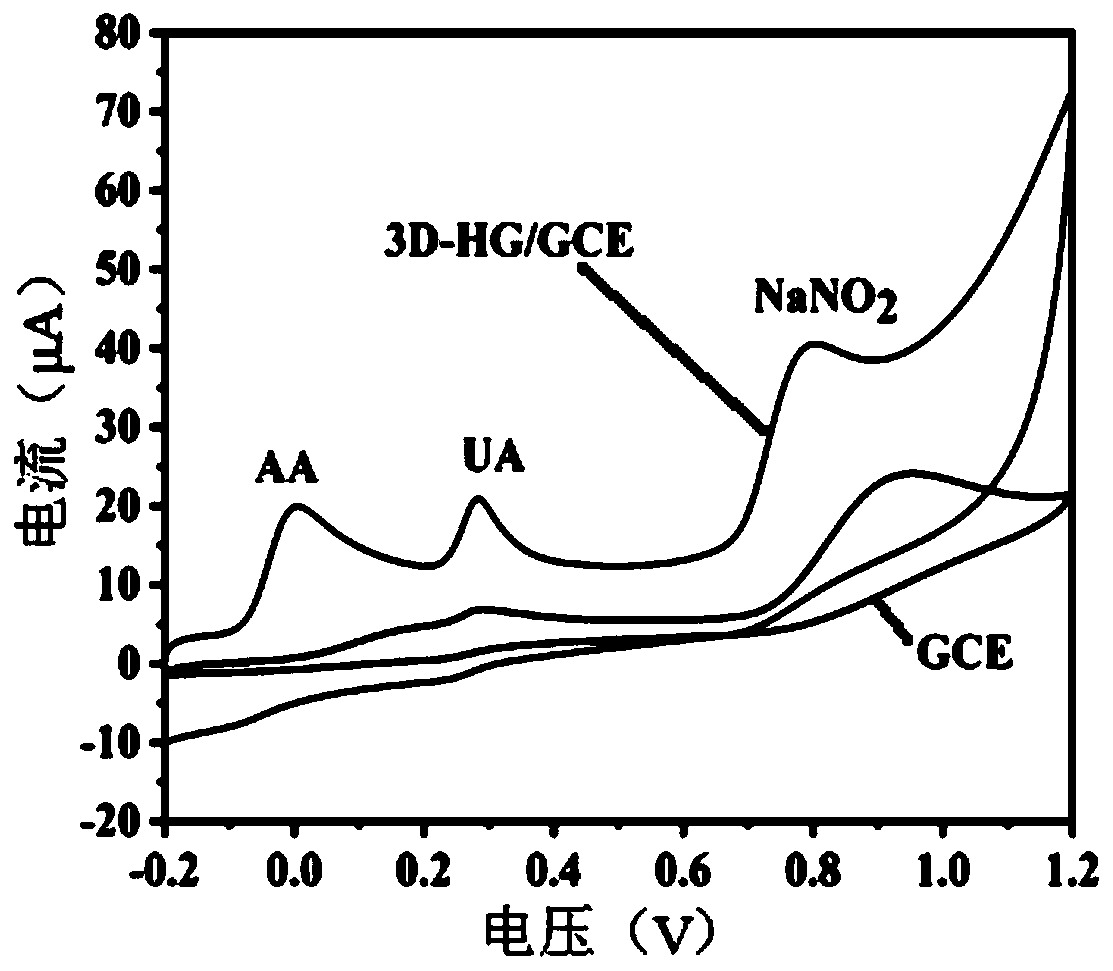

[0035] The three-dimensional porous graphene-based electrochemical electrode material was prepared by the following steps: 6 μL of three-dimensional porous graphene suspension (0.1 mg / mL) was added dropwise to the center of the electrode substrate, and vacuum-dried at room temperature to o...

Embodiment 2

[0037] Adopt hydrothermal method to prepare three-dimensional porous graphene material, concrete steps are: get 10mL graphene oxide (2mg / mL) aqueous solution, add 1mL hydrogen peroxide solution (0.5wt.%), ultrasonic treatment 13min, then graphene oxide and The mixed solution of hydrogen peroxide was transferred to a high-pressure reactor, and reacted at a high temperature of 180°C for 5 hours. The resulting product was immersed in ultrapure water and washed for 2 days to remove excess hydrogen peroxide impurities, and then quickly frozen in liquid nitrogen and placed in Freeze-drying was continued for 12 hours in a freeze-dryer to obtain a three-dimensional porous graphene material solid.

[0038] Three-dimensional porous graphene-based electrochemical electrode materials were prepared by the following steps: 6 μL of three-dimensional porous graphene suspension (0.2 mg / mL) was added dropwise to the center of the electrode substrate, and vacuum-dried at room temperature to obtai...

Embodiment 3

[0049] Adopt hydrothermal method to prepare three-dimensional porous graphene material, concrete steps are: get 10mL graphene oxide (2mg / mL) aqueous solution, add 1mL hydrogen peroxide solution (0.75wt.%), ultrasonic treatment 15min, then graphene oxide and The mixed solution of hydrogen peroxide was transferred to a high-pressure reactor, and reacted at a high temperature of 180°C for 6 hours. The resulting product was immersed in ultrapure water and washed for 2 days to remove excess hydrogen peroxide impurities, and then quickly frozen in liquid nitrogen and placed in a Freeze-drying was continued for 12 hours in a freeze-dryer to obtain a three-dimensional porous graphene material solid.

[0050] Three-dimensional porous graphene-based electrochemical electrode materials were prepared by the following steps: 6 μL of three-dimensional porous graphene suspension (0.3 mg / mL) was added dropwise to the center of the electrode substrate, and vacuum-dried at room temperature to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com