Method for preparing brown coal adsorption material

An adsorption material, lignite technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems that adsorption materials are not suitable for azo organic wastewater, not suitable for recycling fuels, etc. Electronegativity and wettability are improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

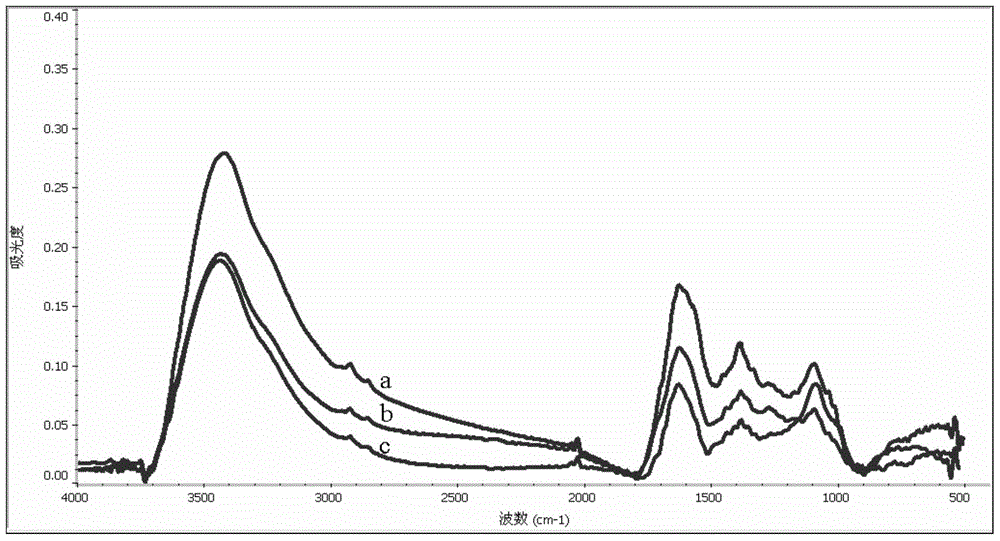

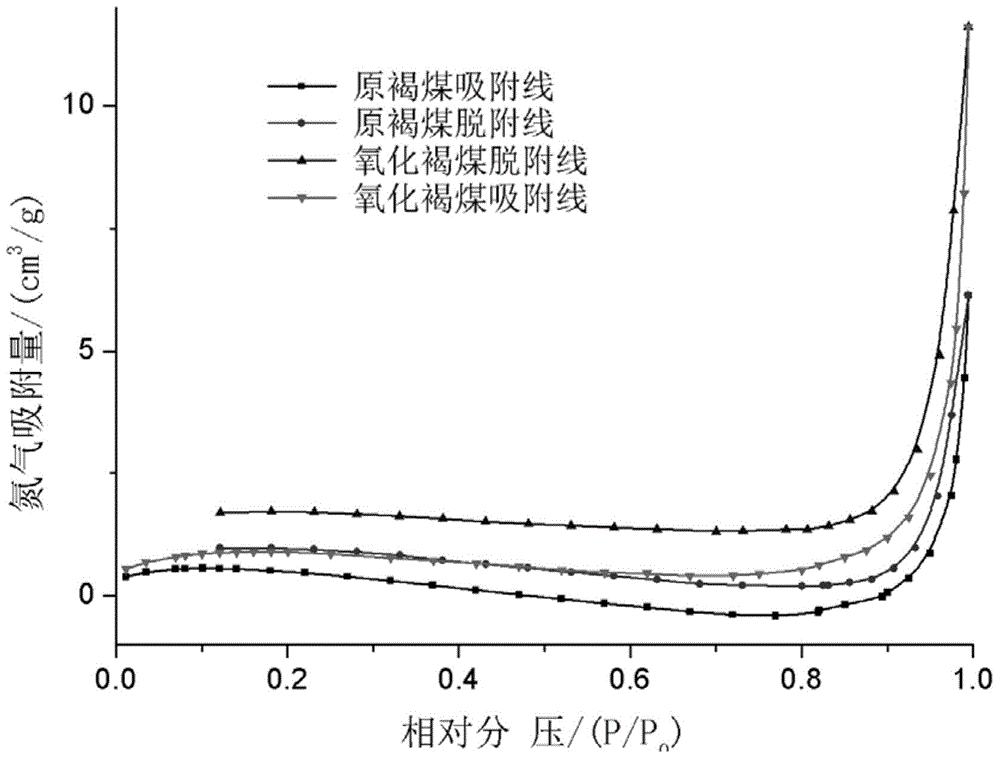

[0014] The embodiment of the present invention provides a kind of preparation method of lignite adsorption material, and this method comprises:

[0015] Using lignite powder as raw material, the lignite adsorption material is obtained after the raw material is oxidized and modified.

[0016] In the above method, the fineness of the lignite powder used as raw material is 20-70 μm.

[0017] In the above method, as raw material lignite powder is prepared in the following ways, including:

[0018] The primary lignite is crushed, the crushed particle size is less than 20mm, and then dried in a drying box at 110°C for two hours to remove the surface adsorption water and internal capillary water of the lignite;

[0019] The dried lignite is ball milled in a horizontal ball mill. The operating parameters of the ball mill are: ball mill steel cylinder Ф90cm×180cm, motor power 15kw, steel cylinder speed 38r / min, built-in steel ball weight 1.8t, steel ball ratio Ф40: Ф60=35%: 65% (mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com