Chip resistor

A chip resistor, resistive film technology, applied in resistors, resistor parts, non-adjustable metal resistors, etc., can solve the problems of low heat transfer to the printed substrate and high temperature of the resistive film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. However, in these drawings, the same reference numerals are assigned to the same or similar components.

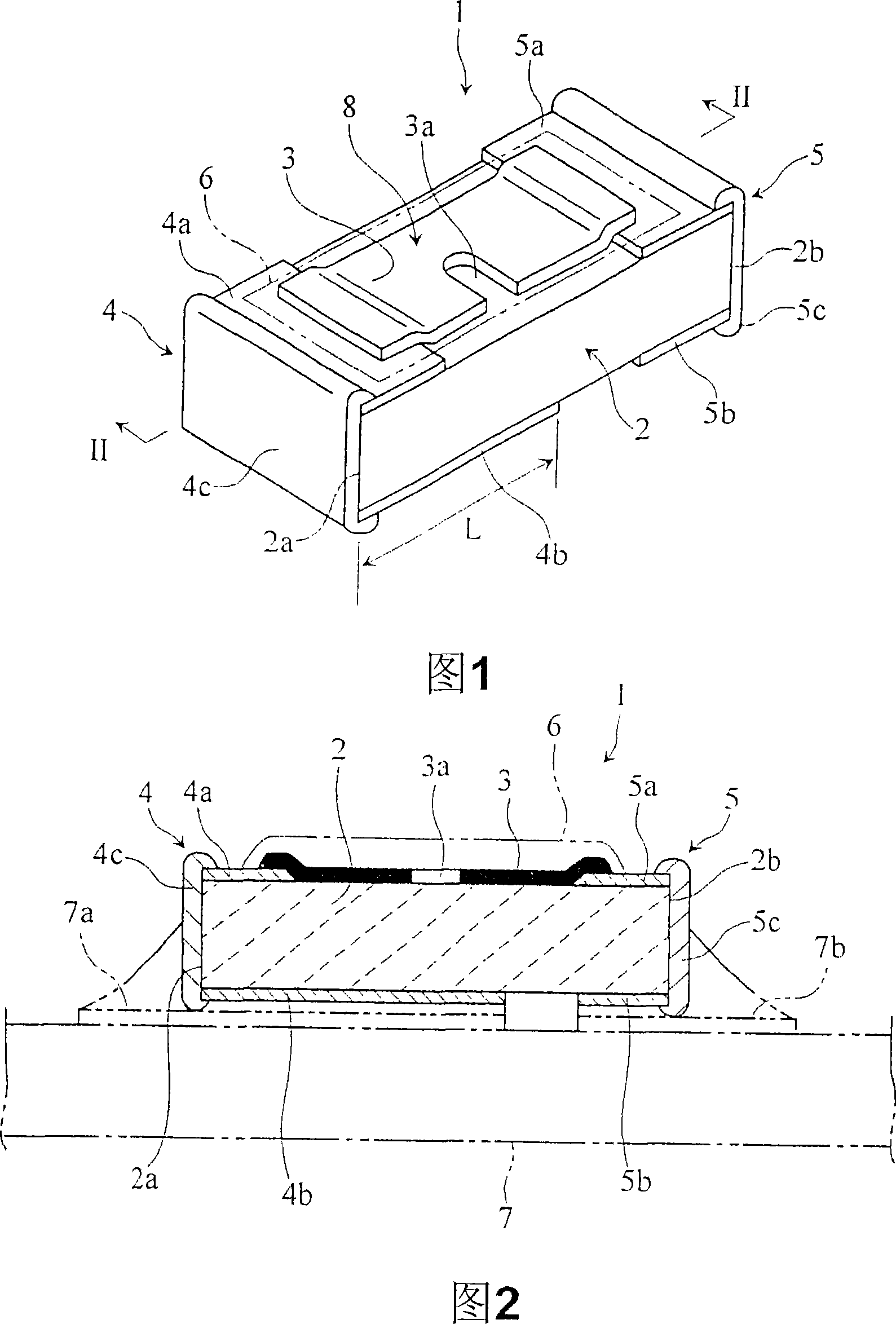

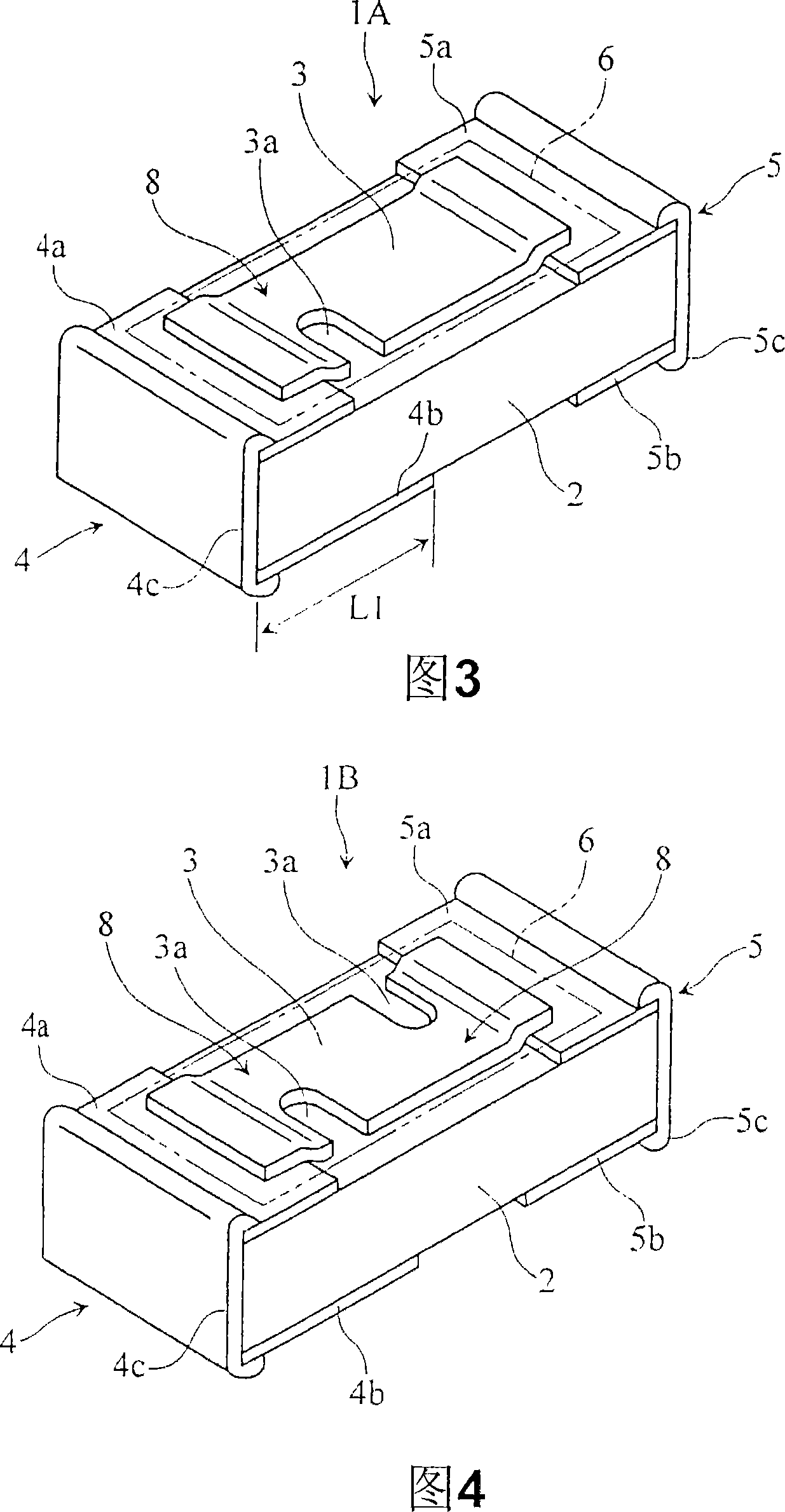

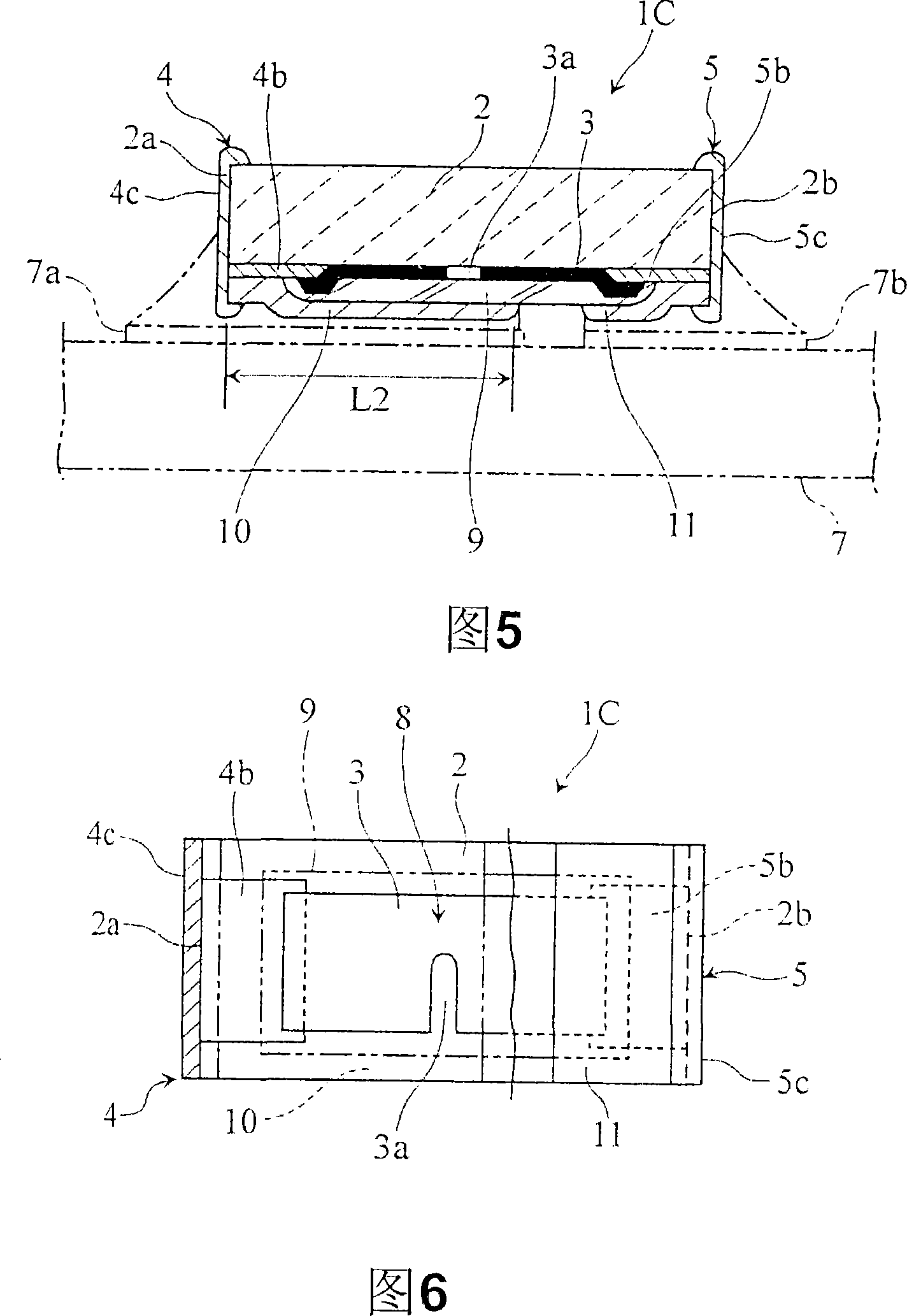

[0025] 1 and 2 are schematic diagrams showing a chip resistor 1 according to a first embodiment of the present invention.

[0026] In this chip resistor 1 , a pair of terminal electrodes 4 and 5 are provided on both ends of an insulating substrate 2 constituting a chip type (rectangular thin plate in plan view). A pair of terminal electrodes 4, 5 are formed on the upper surface of the insulating substrate 2 by upper electrodes 4a, 5a; lower electrodes 4b, 5b formed on the lower surface of the insulating substrate 2; On the upper side, the side electrodes 4c, 5c formed to conduct with the upper electrodes 4a, 5a and the lower electrodes 4b, 5b are formed.

[0027] On the upper surface of the insulating substrate 2 , a resistive film 3 is formed to extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com