Semiconductor element and its forming method

A semiconductor and component technology, applied in the field of metal oxide semi-components, can solve the problems of high LDD sheet resistance, high activation degree, low arsenic activation degree, etc., and achieve the effects of low sheet resistance, reduced phosphorus diffusion, and high activation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

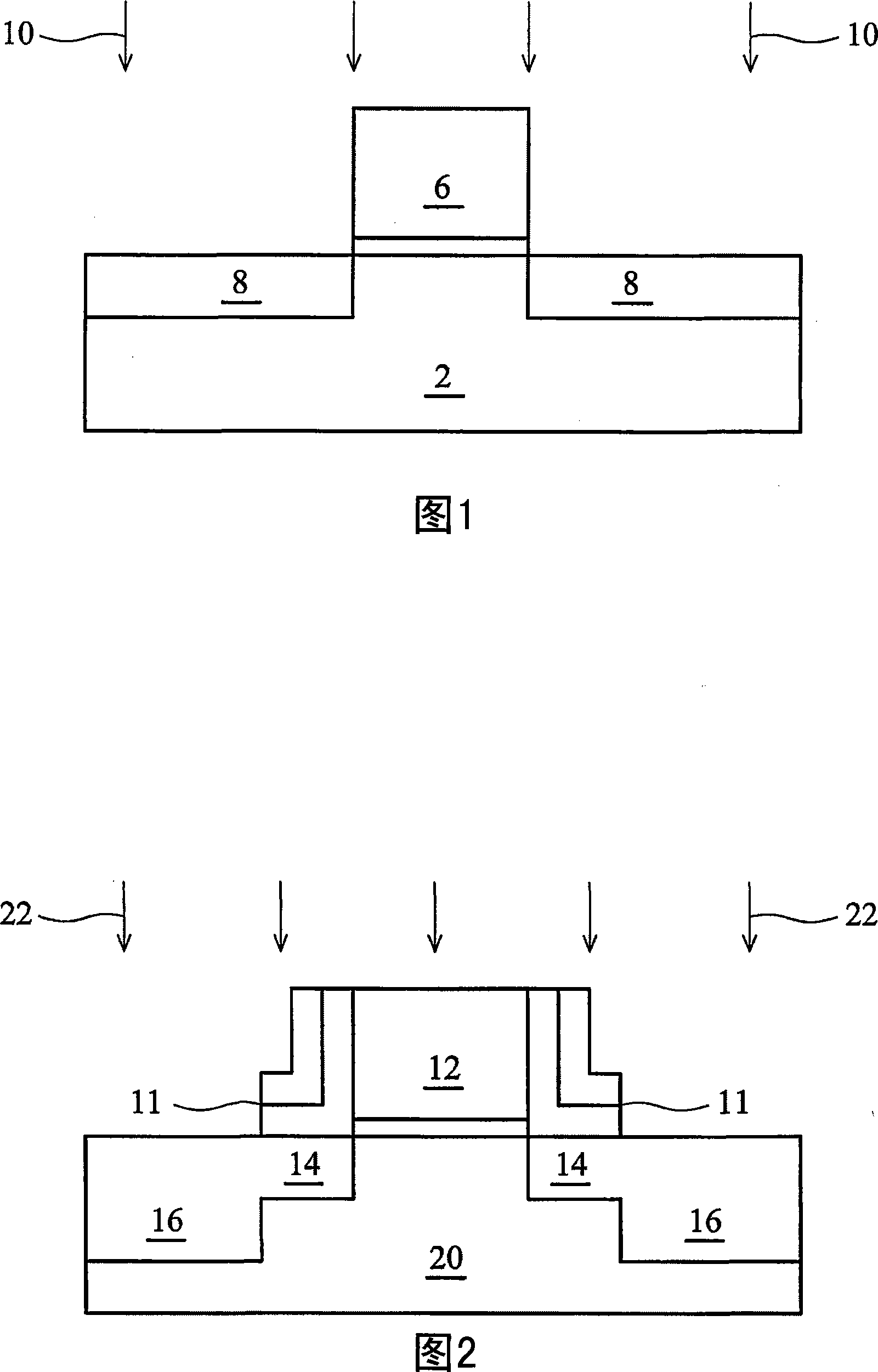

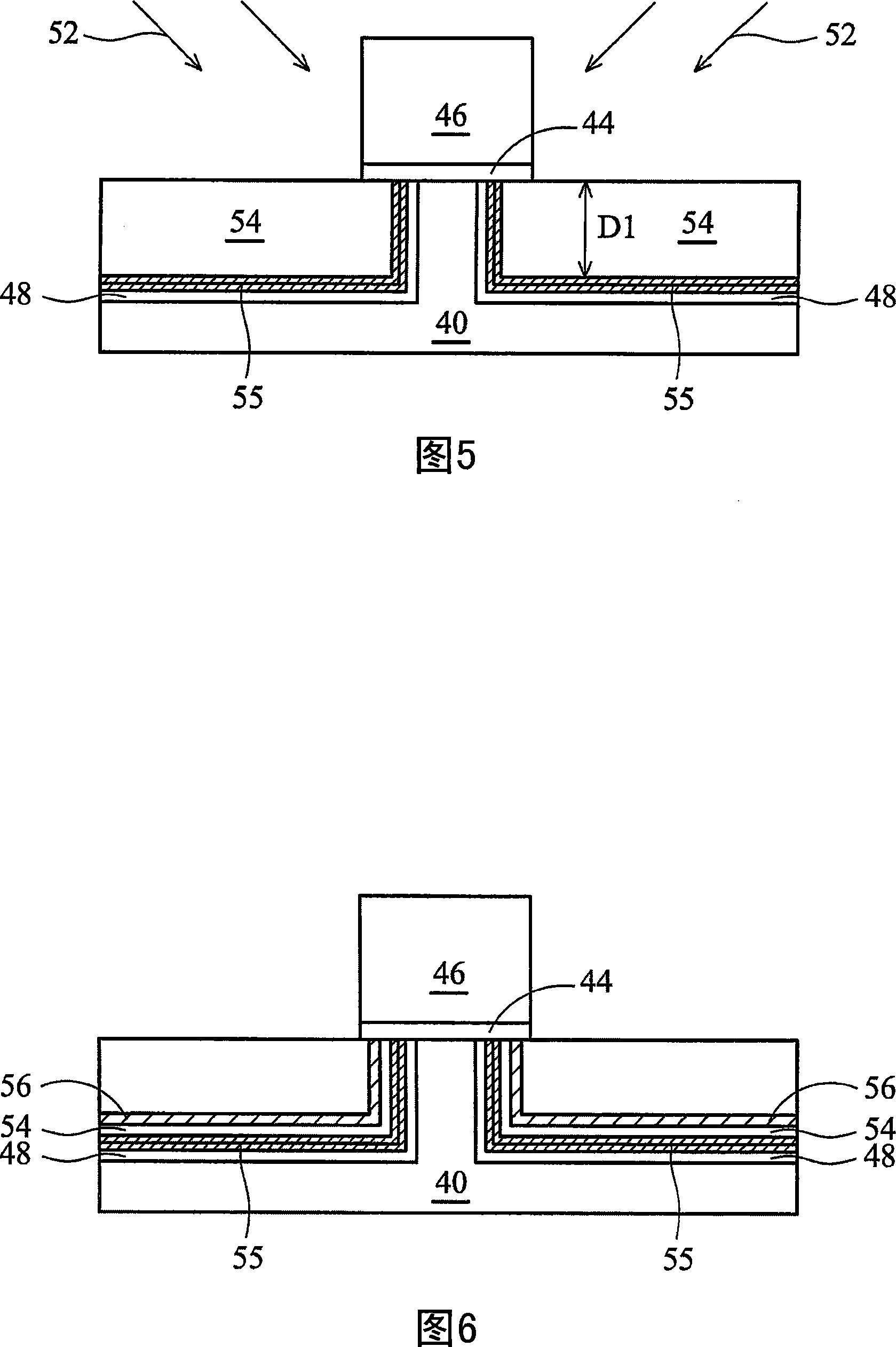

[0026] In high-performance NMOS devices, the source / drain regions preferably have low sheet resistance and shallow junctions. However, these two requirements are often contradictory. In order to reduce the sheet resistance, more activating impurities must be used, which will diffuse the impurities in the implanted region and increase the junction depth. In a preferred embodiment of the present invention, the impurity of the source / drain extension (also called lightly doped source / drain region, LDD region for short) is phosphorus. In the case of controlling the diffusion of phosphorus, the LDD region of the preferred embodiment of the present invention has a high concentration of phosphorus. 3-8C show process cross-sectional views of a preferred embodiment of the present invention. In different drawings, the same elements are labeled with the same reference numerals.

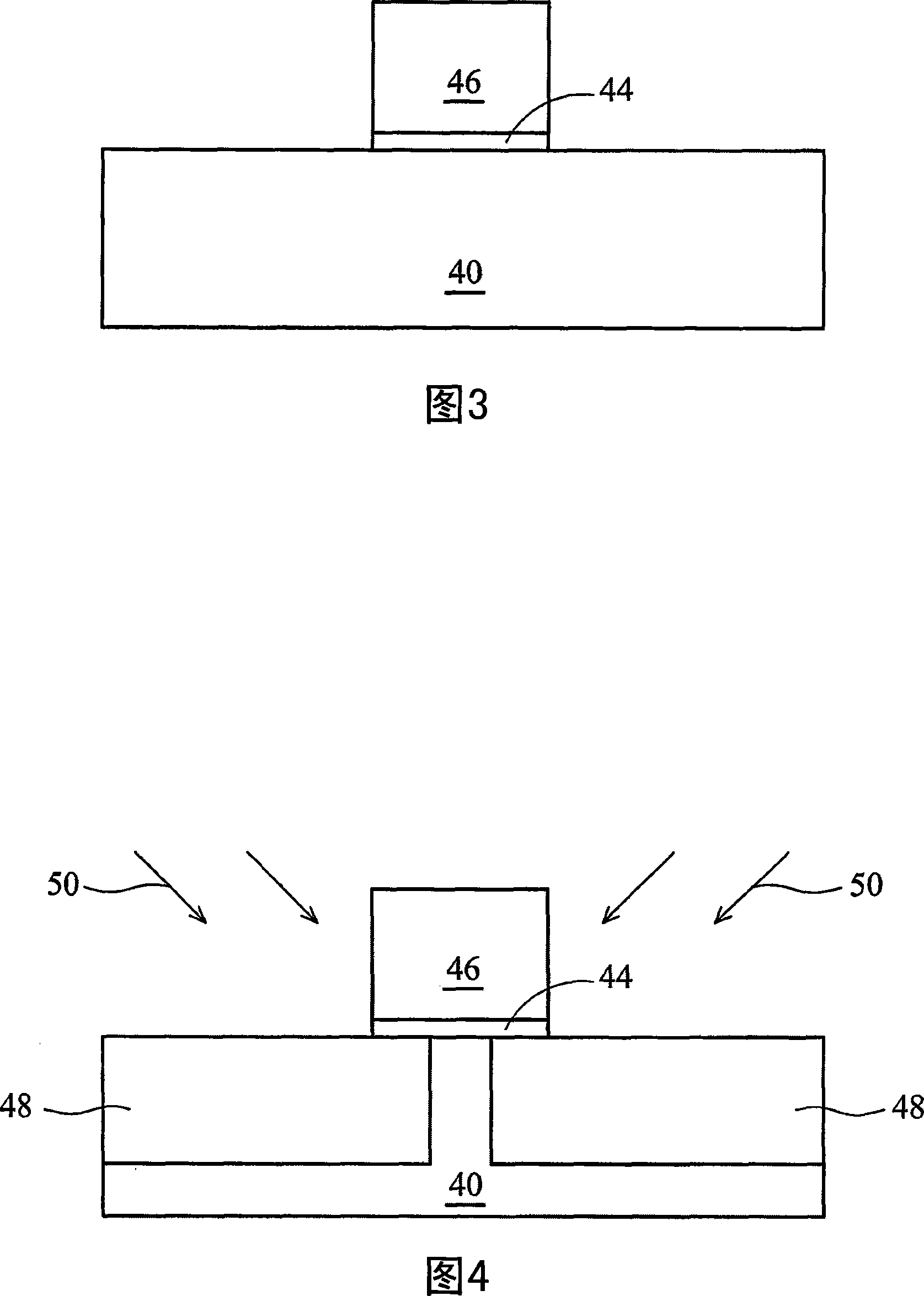

[0027] In FIG. 3, the gate dielectric layer 44 of the gate stack is formed on the substrate 40, and the gate 46 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com