Superhydrophilic anticorrosion coating sol and preparation method and application thereof

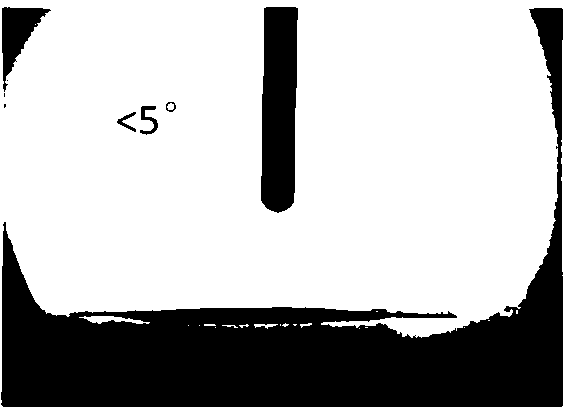

An anti-corrosion coating and super-hydrophilic technology, applied in the direction of anti-corrosion coatings, coatings, fire-resistant coatings, etc., to achieve the effects of promoting application and development, simple preparation process, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

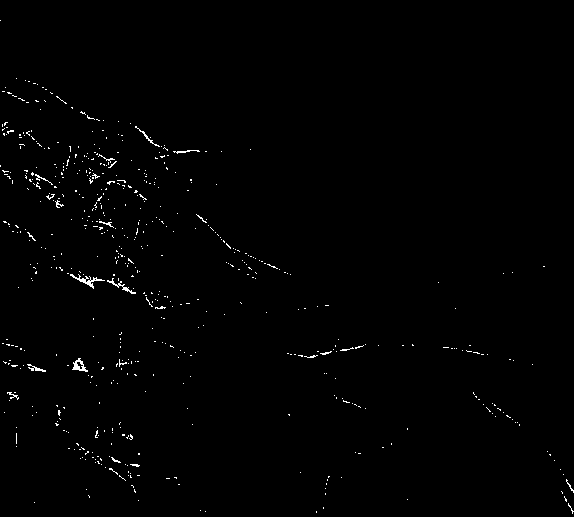

[0043] (1) Preparation of graphene solution

[0044] Mix 10g graphene material (graphene, size 100~1000nm, layer number 1~5 layers), 0.01g hexamethyldisilazane, 1000g solvent, and disperse evenly under ultrasonic conditions to obtain graphene solution;

[0045] (2) Preparation of superhydrophilic anti-corrosion coating sol

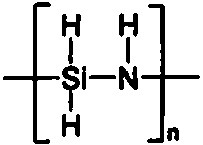

[0046] Mix the graphene solution obtained in step (1) with 1000 g of an inorganic polysilazane solution with a solid content of 5% and a solvent, stir in a sealed state at 35°C for 10 hours, and store in a sealed state to obtain a superhydrophilic solution with a solid content of 1.5%. Anti-corrosion coating sol. The inorganic polysilazane solution used comprises inorganic polysilazane, solvent and catalyst 4,4'-trimethylenebis(1-methylpiperidine), wherein the mass ratio of inorganic polysilazane and catalyst is 10 :0.01.

[0047] Apply the super-hydrophilic anti-corrosion coating sol film on the substrate, and cure it at 100°C for 1 hour to obtain the ...

Embodiment 2

[0049] (1) Preparation of graphene solution

[0050] Mix 10g of graphene material (graphene, size 0.1~50nm, layer number 1~100 layers), 1g hexamethyldisilazane, 5000g solvent, and disperse evenly under ultrasonic conditions to obtain graphene solution;

[0051] (2) Preparation of superhydrophilic anti-corrosion coating sol

[0052]Mix the graphene solution obtained in step (1) with 10,000 g of an inorganic polysilazane solution with a solid content of 10% and a solvent, stir in a sealed state at 15°C for 30 hours, and store in a sealed state to obtain a superhydrophilic solution with a solid content of 5%. Anti-corrosion coating sol. The inorganic polysilazane solution used contains inorganic polysilazane, n-butyl ether, xylene and catalyst 4,4'-trimethylenebis(1-methylpiperidine), wherein the inorganic polysilazane and catalyst The mass ratio is 10:0.05.

[0053] Apply the super-hydrophilic anti-corrosion coating sol film on the substrate, and cure it at 30°C for 24 hours ...

Embodiment 3

[0055] (1) Preparation of graphene solution

[0056] Mix 10g graphene material (graphene, size 500~50000nm, layer number 1~9 layers), 0.5g hexamethyldisiloxane, 10000g solvent, and disperse evenly under ultrasonic conditions to obtain graphene solution;

[0057] (2) Preparation of superhydrophilic anti-corrosion coating sol

[0058] Mix the graphene solution obtained in step (1) with 10,000 g of an inorganic polysilazane solution with a solid content of 2% and a solvent, stir in a sealed container at 15°C for 30 hours, and store in a sealed container to obtain a superhydrophilic solution with a solid content of 1%. Anti-corrosion coating sol. The used inorganic polysilazane solution comprises inorganic polysilazane, solvent and catalyst 1-methylpiperidine, wherein the mass ratio of inorganic polysilazane and catalyst is 10:0.001.

[0059] Apply the super-hydrophilic anti-corrosion coating sol film on the substrate, and cure it at 120°C for 14 hours to obtain the super-hydrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com