Low-density and high-strength heat-conducting silica gel gasket

A thermally conductive silica gel, high-strength technology, applied in the field of thermally conductive materials, can solve the problems of limited application fields, difficult processing, high brittleness, etc., and achieve the effects of low density, simple and easy preparation, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

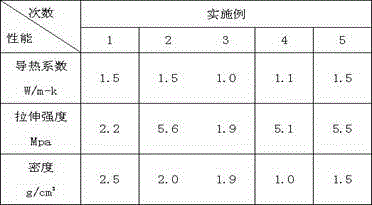

Examples

Embodiment

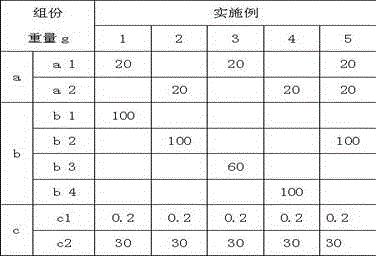

[0014] 1. Raw materials are prepared as follows:

[0016] a1. Mixture of vinyl silicone oil (vinyl content 0.18%) and hydrogen silicone oil (hydrogen content 0.22%)

[0017] a2. Vinyl silicone oil (vinyl content 0.18%), vinyl silicone resin (vinyl content 2%)

[0018] b. Thermally conductive powder

[0019] b1. Alumina powder (D50=0.5~70μm) b2. Alumina aluminosilicate powder (D50=35~70μm)

[0020] b3. Boron nitride powder (D50=0.5~10μm) b4. Silicon dioxide powder (D50=8~40μm)

[0021] C. Auxiliary

[0022] C1 Coupling agent, catalyst C2. Combustion aid

[0023] After the above-mentioned heat-conducting powder is dried, the proportioning is carried out according to the ratio shown in the following table 1, and the surface treatment of the proportioned powder is carried out by a wet method, so that the surface of the powder is coated with a layer of coupling agent, and the silicone polymer is mixed separately. The material is put into a planeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com