Cadmium telluride solar cell assembly with thermal insulation layer and preparation method thereof

A technology of solar cells and cadmium telluride, which is applied in the field of solar cells, can solve problems such as poor thermal insulation, failure to meet external wall thermal insulation requirements, and large thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

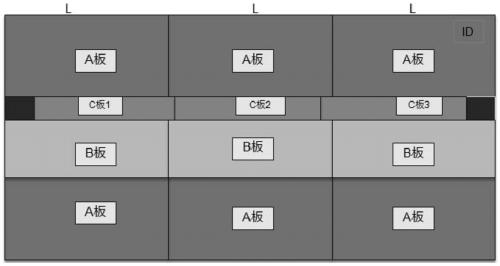

[0038] A cadmium telluride solar cell module with a thermal insulation layer, comprising from bottom to top: cadmium telluride power generation glass, a silica gel layer and a thermal insulation layer, the thermal insulation layer includes four layers of heat insulation board layers, and each layer of heat insulation The board layer is formed by horizontal splicing of three heat insulation boards. The inside of the heat insulation board is thermal insulation material, and the outer surface of the heat insulation board is provided with PET / AL / PE composite film (commercially available aluminum foil bag)

[0039] in,

[0040] The silica gel material of the silica gel layer is Tianshan silica gel, model: 1527 (commercially available); the thickness of the silica gel layer is 2-4mm;

[0041] The insulation material is polyurethane foam;

[0042]The heat insulation layer includes from bottom to top: the first heat insulation board layer, the second heat insulation board layer, the ...

Embodiment 2

[0065] The only difference between this embodiment and Embodiment 1 is that the thermal insulation material is phenolic resin foam.

Embodiment 3

[0067] The difference between this embodiment and embodiment 1 is only that: the thermal insulation material is polystyrene foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com