Nano zinc oxide / polypropylene / polylactic acid composite fiber material and preparing method thereof

A technology of nano-zinc oxide and composite fiber, which is applied in the direction of fiber chemical characteristics, conjugated synthetic polymer rayon, rayon manufacturing, etc., can solve the problems of poor compatibility, improve dispersibility, improve spinnability and Effect of fiber forming strength and uniform particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

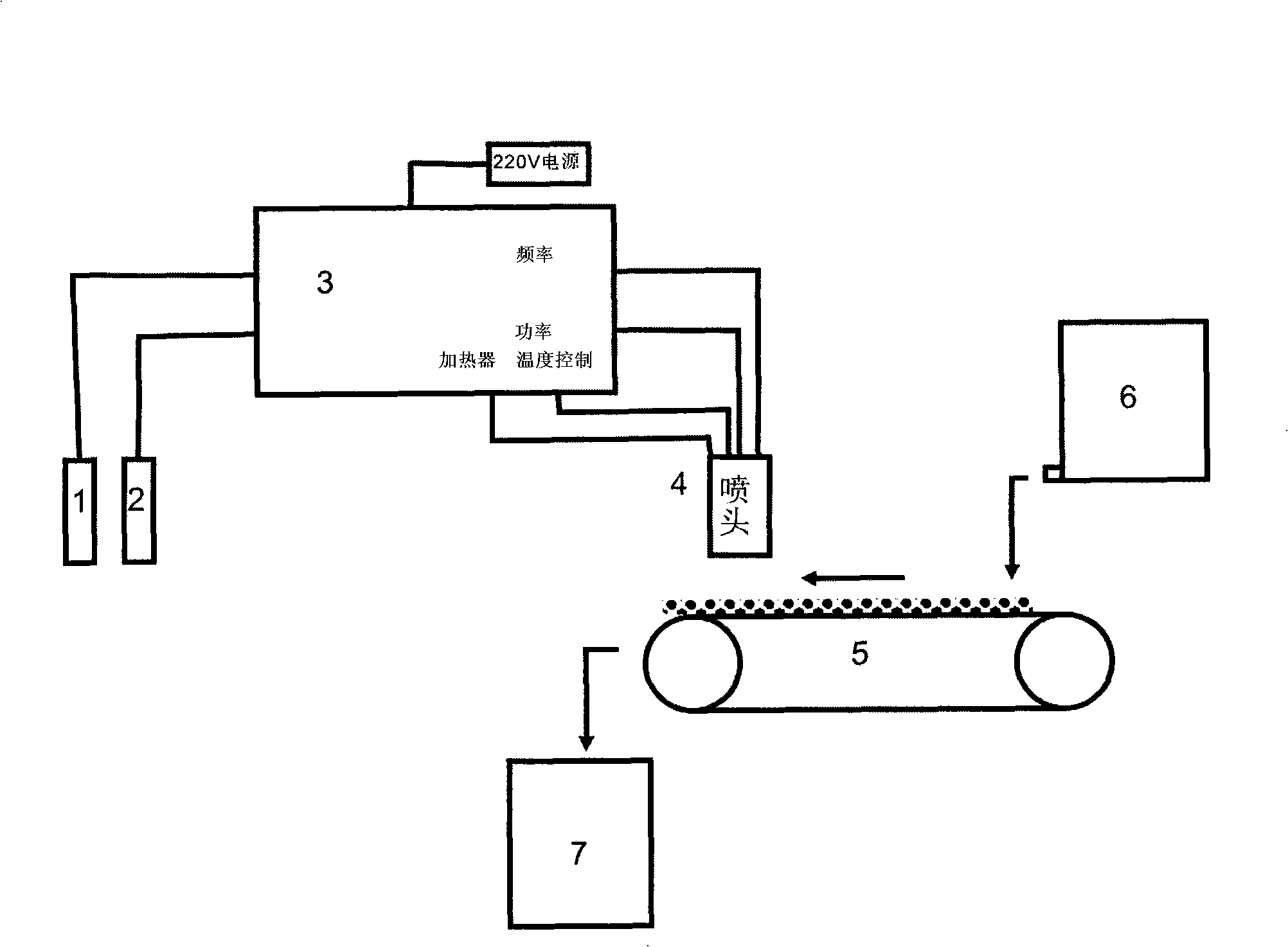

[0035] Process for processing nano zinc oxide / polypropylene / polylactic acid composite wire by helium plasma treatment

[0036] (1) Take 50 grams of commercial nano-zinc oxide powder produced by Zhejiang Hongsheng Powder Co., Ltd. or self-made nano-zinc oxide powder and place it on the special transmission device of the plasma processing equipment. Schematic diagram such as figure 1 (Or add a channel with a plasma nozzle), the container or carrier is placed within a specific distance of 2 cm below the nozzle of the normal pressure\normal temperature plasma spray device (the design of the nozzle part of the channel is based on specific requirements), and the thickness of the nanopowder Lay at a thickness of 5 mm, and under the premise of opening normal pressure and room temperature plasma, the container or carrier moves at a specific speed. The nano zinc oxide powder can be obtained under helium plasma atmosphere, power 40 watts and 5 seconds deal with.

[0037] (2) The normal pres...

Embodiment 2

[0041] Oxygen plasma treatment nano-zinc oxide / polypropylene / polylactic acid composite wire processing technology

[0042] (1) Take 50 grams of commercial nano-zinc oxide powder produced by Zhejiang Hongsheng Powder Co., Ltd. or self-made nano-zinc oxide powder and place it on the special transmission device of the plasma processing equipment. Schematic diagram such as figure 1 (Or add a channel with a plasma nozzle), the container or carrier is placed within a specific distance of 2 cm below the nozzle of the normal pressure\normal temperature plasma spray device (the nozzle part of the channel is designed according to specific requirements), and the thickness of the nanopowder is laid Lay at a thickness of 5 mm, and under the premise of opening normal pressure and room temperature plasma, the container or carrier moves at a specific speed. The carbon nano powder can be processed in an oxygen plasma atmosphere, a power of 40 watts and a time of 5 seconds.

[0043] (2) The normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com