Stainless steel powder for additive manufacturing, and preparation method thereof

It is a technology of additive manufacturing and powder preparation, which is applied in the field of metal and alloy powder preparation. It can solve the problems that the oxygen content of the powder is easy to rise, it is difficult to meet the high-performance metal, and the particle size of the powder is difficult to control. Fluidity, simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

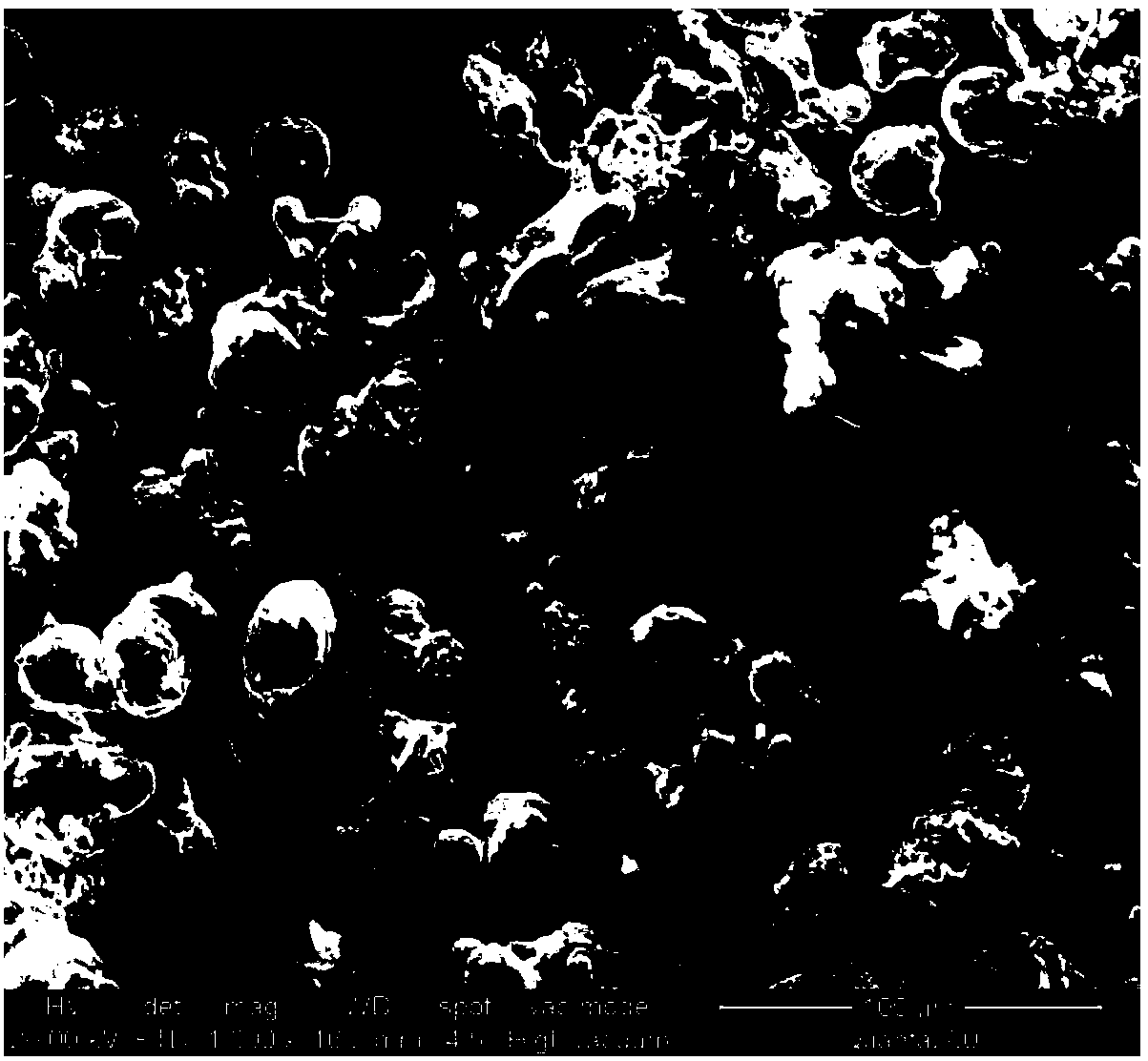

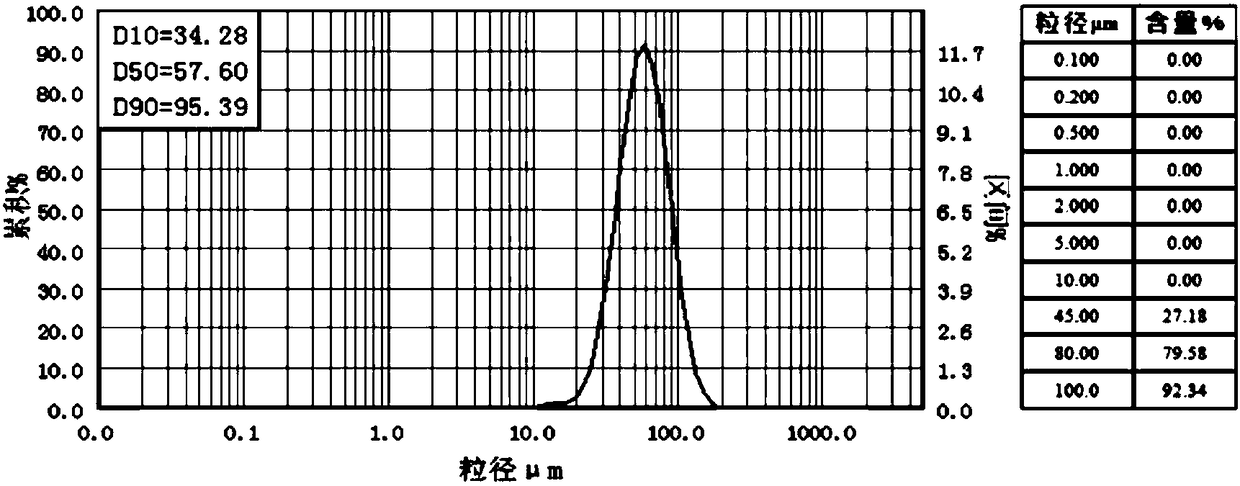

[0037] Stainless steel powder preparation method, the steps are as follows:

[0038] (1) In the sieving system of Artech Swiss ultrasonic sieving machine, the original stainless steel powder A is classified and processed to obtain the stainless steel powder B suitable for the particle size distribution of additive manufacturing. The effective screening diameter of the sieve is φ520mm, and the size of the sieve is 325 mesh and 500 mesh;

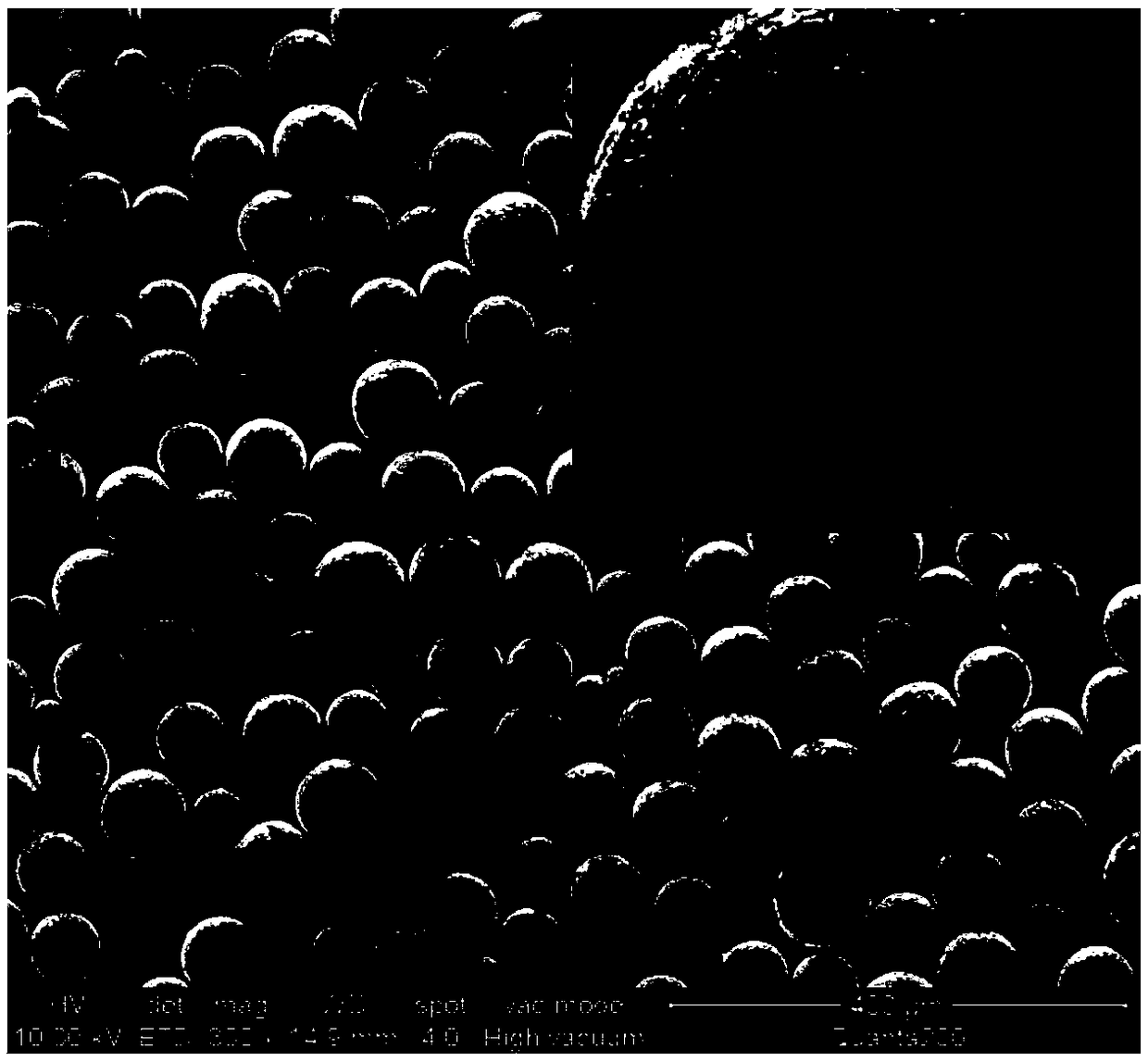

[0039](2) In the spheroidization of the Tekna plasma system TekNano-40NanopowderSynthesissystem, the stainless steel powder B is spheroidized to obtain the stainless steel powder C. Among them, the system parameters are: the sheath gas of the plasma system is argon-hydrogen mixed gas, the flow rate of argon is 60L / min, and the flow rate of hydrogen is 15L / min; the central gas of the plasma system is argon, and the flow rate is 35L / min. The carrier gas of the plasma system is argon with a flow rate of 10 L / min. The powder feeding rate is 80g / ...

Embodiment 2

[0044] Stainless steel powder preparation method, the steps are as follows:

[0045] (1) In the sieving system of Artech Swiss ultrasonic sieving machine, the original stainless steel powder A is classified and processed to obtain the stainless steel powder B suitable for the particle size distribution of additive manufacturing. The effective screening diameter of the sieve is φ520mm, and the size of the sieve is 325 mesh and 500 mesh;

[0046] (2) In the spheroidization of the Tekna plasma system TekNano-40NanopowderSynthesissystem, the stainless steel powder B is spheroidized to obtain the stainless steel powder C. Among them, the system parameters are: the sheath gas of the plasma system is argon-hydrogen mixed gas, the flow rate of argon is 60L / min, and the flow rate of hydrogen is 10L / min; the central gas of the plasma system is argon, and the flow rate is 35L / min. The carrier gas of the plasma system is argon with a flow rate of 10 L / min. The powder feeding rate is 100...

Embodiment 3

[0052] Stainless steel powder preparation method, the steps are as follows:

[0053] (1) In the sieving system of Artech Swiss ultrasonic sieving machine, the original stainless steel powder A is classified and processed to obtain the stainless steel powder B suitable for the particle size distribution of additive manufacturing. The effective screening diameter of the sieve is φ520mm, and the size of the sieve is 325 mesh and 500 mesh;

[0054] (2) In the spheroidization of the Tekna plasma system TekNano-40NanopowderSynthesissystem, the stainless steel powder B is spheroidized to obtain the stainless steel powder C. Among them, the system parameters are: the sheath gas of the plasma system is argon-hydrogen mixed gas, the flow rate of argon is 80L / min, and the flow rate of hydrogen is 15L / min; the central gas of the plasma system is argon, and the flow rate is 25L / min. The carrier gas of the plasma system is argon with a flow rate of 10 L / min. The powder feeding rate is 60g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com