Process and device for producing slurry of permanent ferrite prefiring material by wet method

A technology of permanent magnet ferrite and pre-fired material, which is applied in the direction of magnetism of inorganic materials, can solve problems such as difficulty in meeting large-scale production, high labor intensity of workers, and particle size that cannot meet the requirements, so as to achieve a small particle size distribution range of the slurry and workers The effect of low labor intensity and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

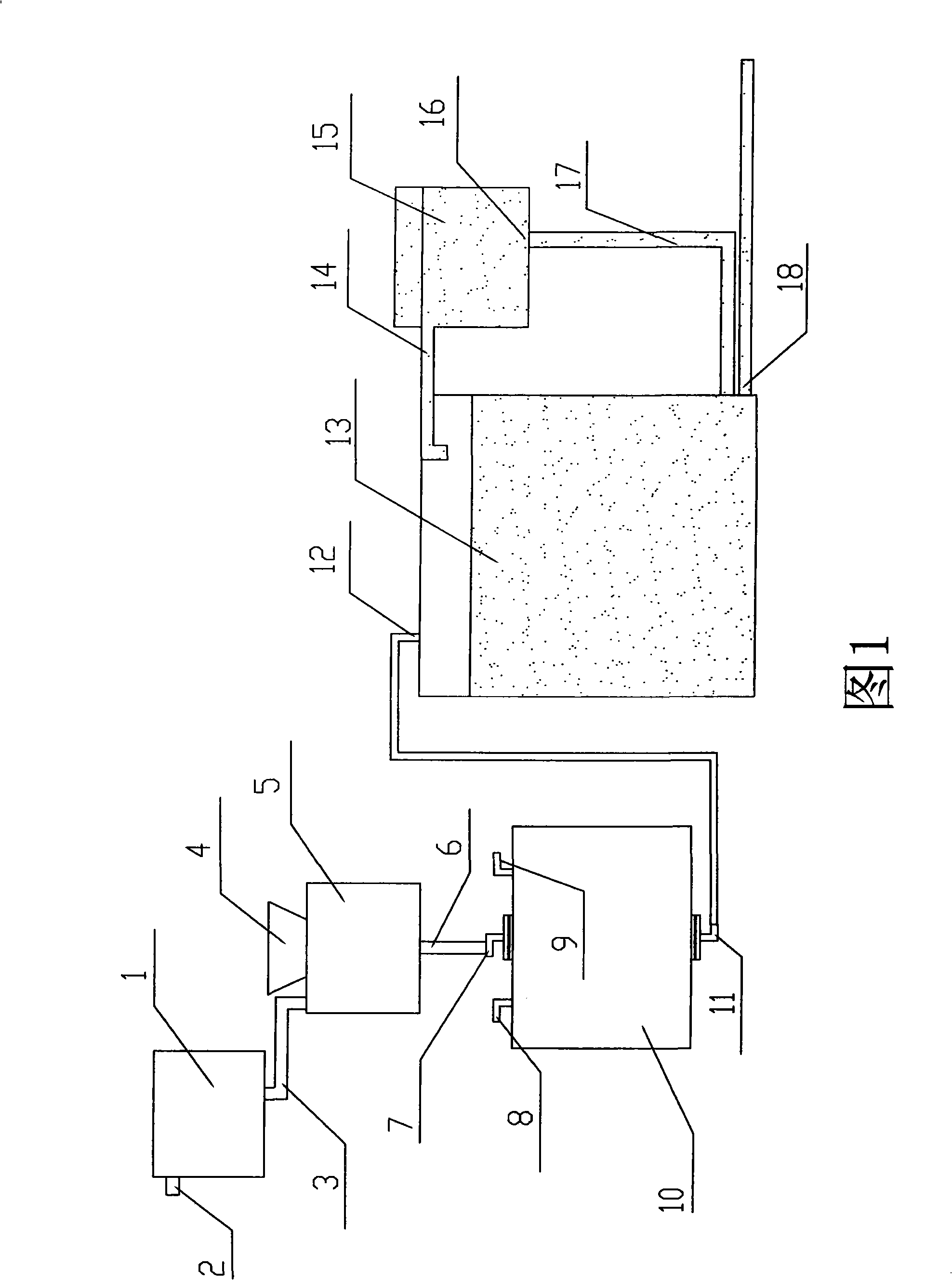

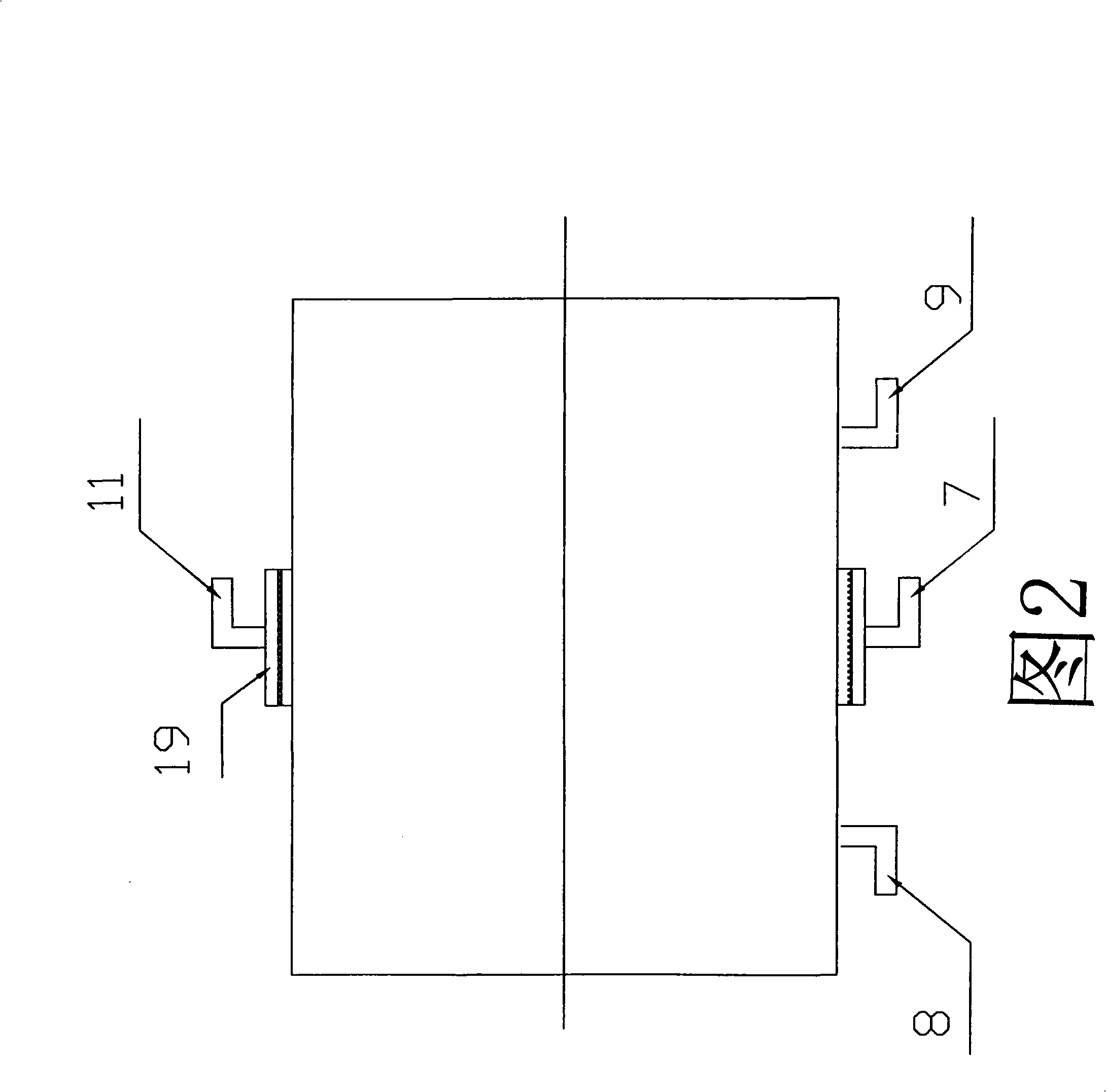

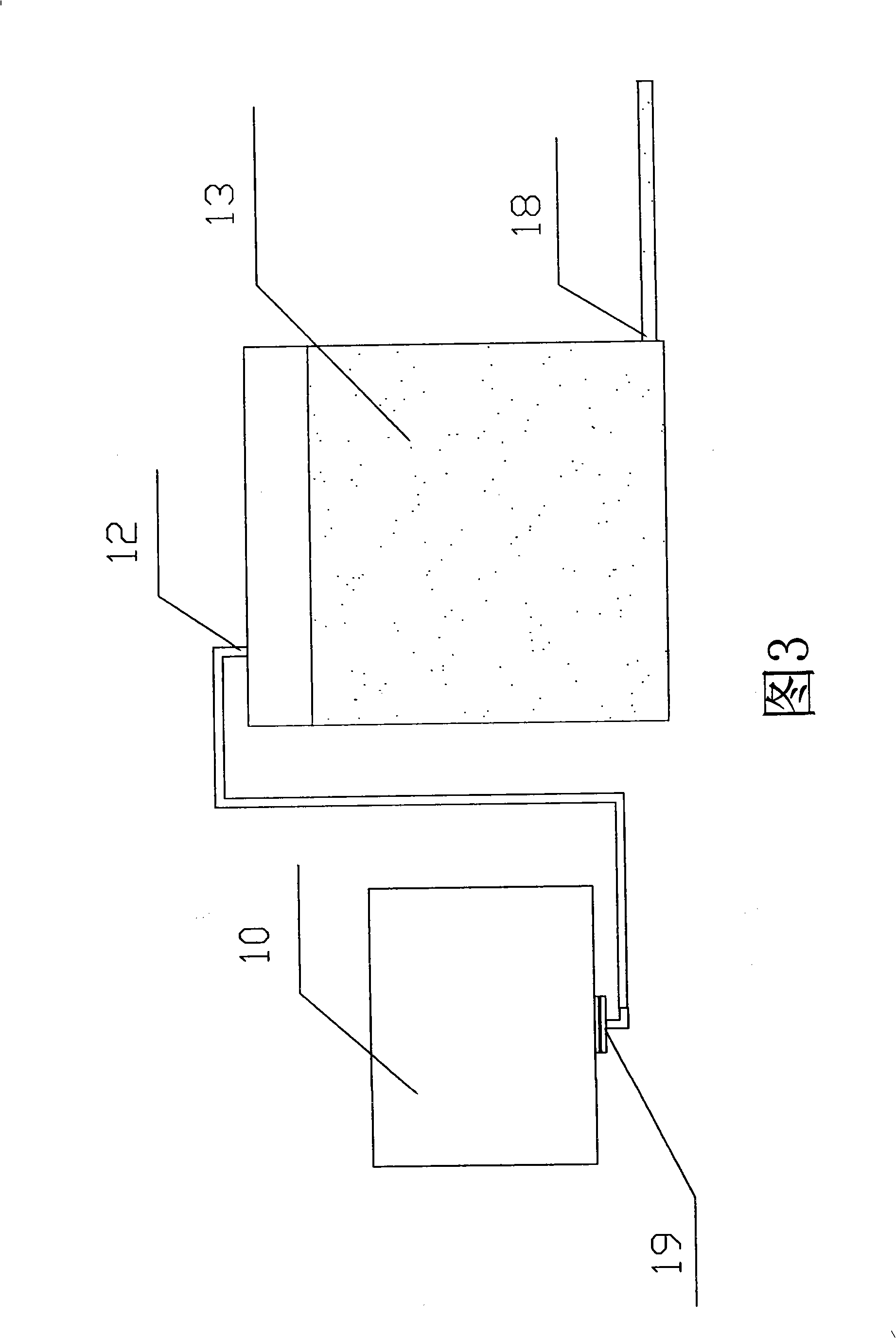

[0021] Referring to Fig. 1, there is a feed hopper 4 above the mixer 5, which is connected to the water tank 1 through a pipeline 3, and the water tank has an overflow hole 2, and the mixer 5 is connected to the feed port 7 of the ball mill through a pipeline 6, and the ball mill has an air intake Holes 9, vent holes 8, door 19, the outlet 11 installed on the door is connected with the feed port 12 of the stirring storage tank 13 through pipelines, the stirring storage tank is connected with the bottom of the sand mill 15 through pipelines 17, The upper part is connected through a pipeline 14, and the lower part of the stirring storage tank is connected with a pipeline 18.

[0022] During installation, the ball mill and the mixing storage tank are installed on the ground, the mixer and the sand mill are respectively installed on the ball mill and the mixing storage tank, and the water tank is installed on the mixer.

[0023] The mixing machine 5 of the present invention adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com