Preparation method of micro-particle-size tadalafil

A technology of tadalafil and microparticles, which is applied in the field of preparation of micro-particle tadalafil, can solve the problems of large energy, complex process, large energy consumption, etc., and achieves small particle size distribution, simple production process, and high yield high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

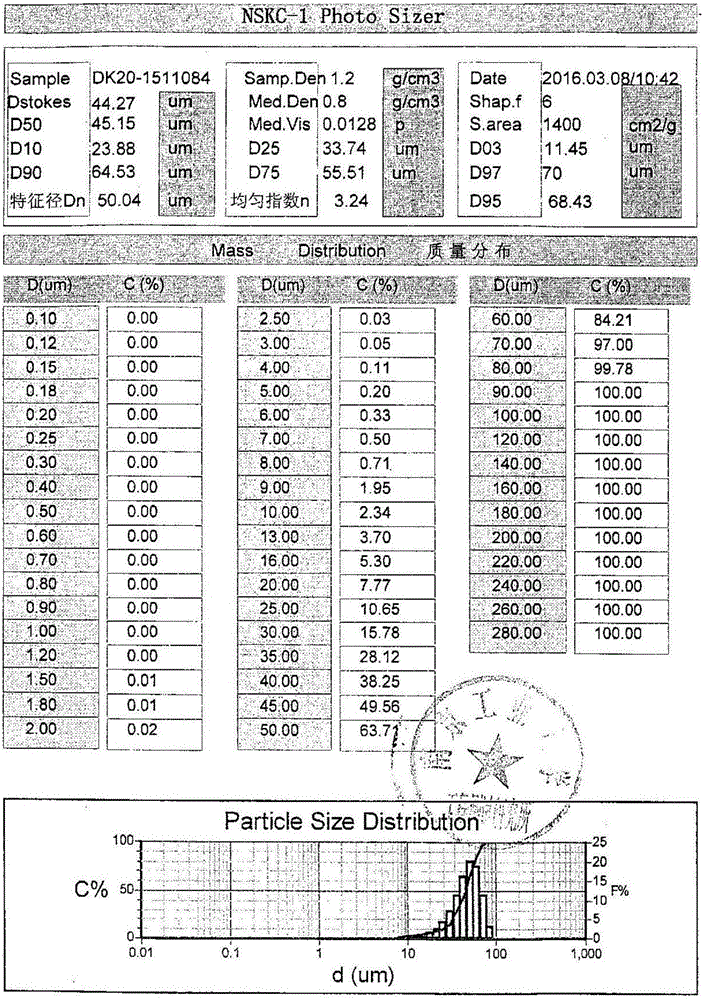

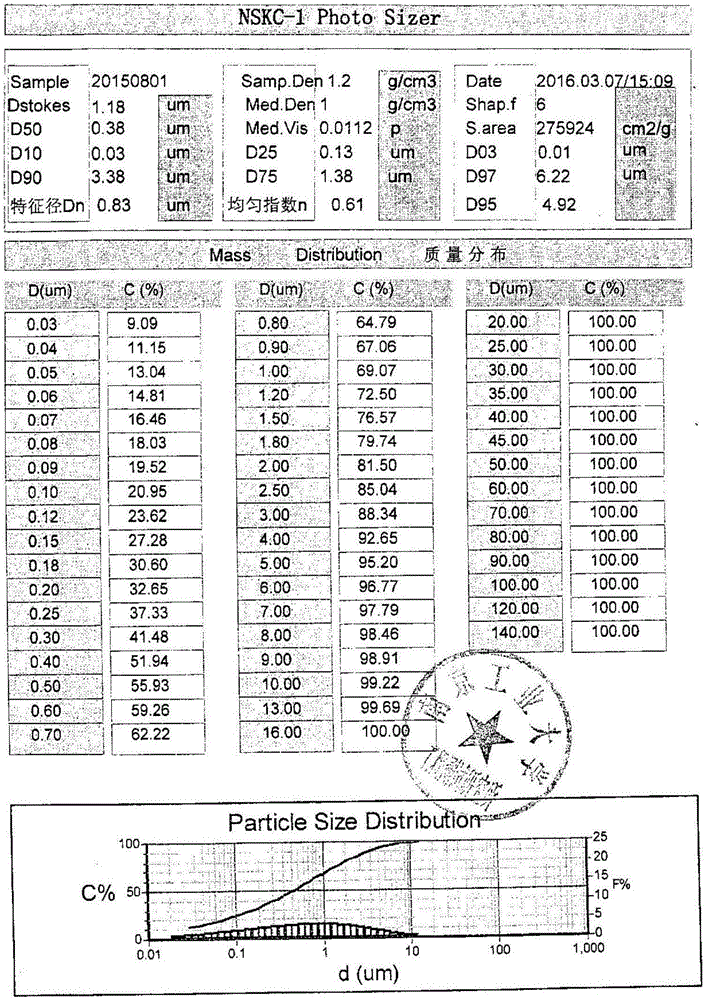

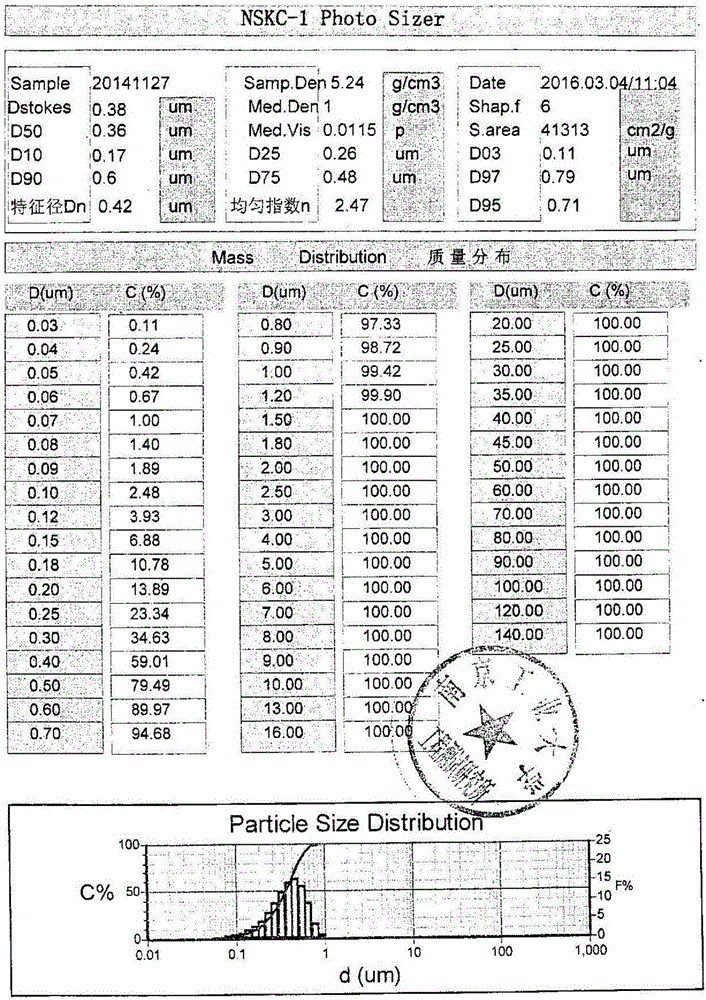

[0033] Take 10g of tadalafil with a D90 of 64.53μm, dissolve it in 10g of dimethyl sulfoxide, stir until clear, and slowly add 5g of water under stirring (propelled stirring 50rpm), stir for 10min, centrifuge, and use 5g of Washed with water three times, and air-dried to obtain 5.37 g of tadalafil with a particle size of 53.7%. As measured by a Malvern particle size analyzer, the particle size D90 of tadalafil was 21.47 μm.

Embodiment 2

[0035]Take 10 g of tadalafil with a D90 of 64.53 μm, dissolve it in 10 g of dimethyl sulfoxide, stir until clear, and slowly add 10 g of water under stirring (propelled stirring 200 rpm), stir for 10 min, centrifuge, and use 5 g of Washed with water three times, and air-dried to obtain 6.48 g of tadalafil with a particle size of 64.8%. As determined by a Malvern particle size analyzer, the particle size D90 of tadalafil was 18.14 μm.

Embodiment 3

[0037] Take 10g of tadalafil with a D90 of 64.53μm, dissolve it in 10g of dimethyl sulfoxide, stir until it becomes clear, slowly add it into 50g of water under stirring (propulsion stirring 500rpm), stir for 10min, centrifuge, and use 5g of Washed with water three times, and air-dried to obtain 8.61 g of tadalafil with a particle size of 86.1%. . As measured by a Malvern particle size analyzer, the particle size D90 of tadalafil was 14.67 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com