Preparation method of graphene-polyester nano-composite fiber

A nano-composite fiber, graphene technology, applied in fiber processing, conductive/antistatic filament manufacturing, single-component polyester rayon, etc., can solve practical limitations, low efficiency, low polyester monofilament strength, etc. problems, to achieve the effect of improving production efficiency and volume, reducing capital investment, and improving breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

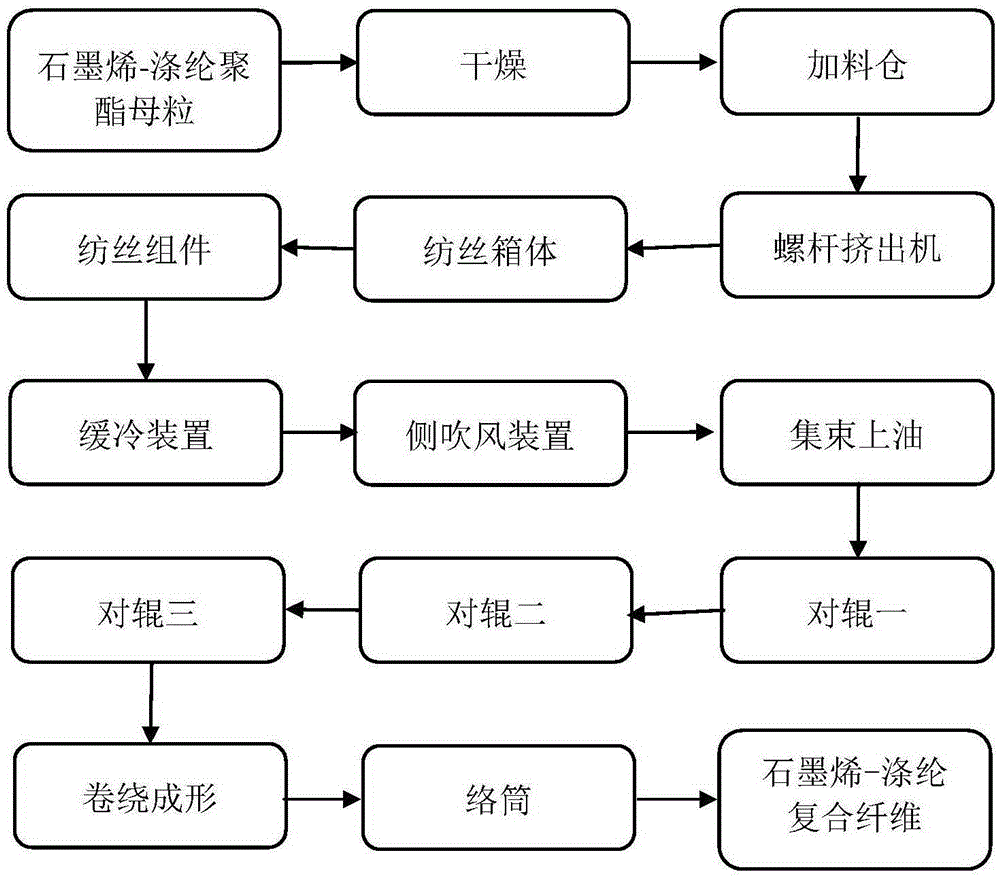

[0045] The present embodiment provides a kind of preparation method of graphene-polyester nanocomposite fiber, comprises the following steps: the preparation step of graphene-polyester polyester composite masterbatch and the preparation step of described composite masterbatch into graphene-polyester nanocomposite fiber step;

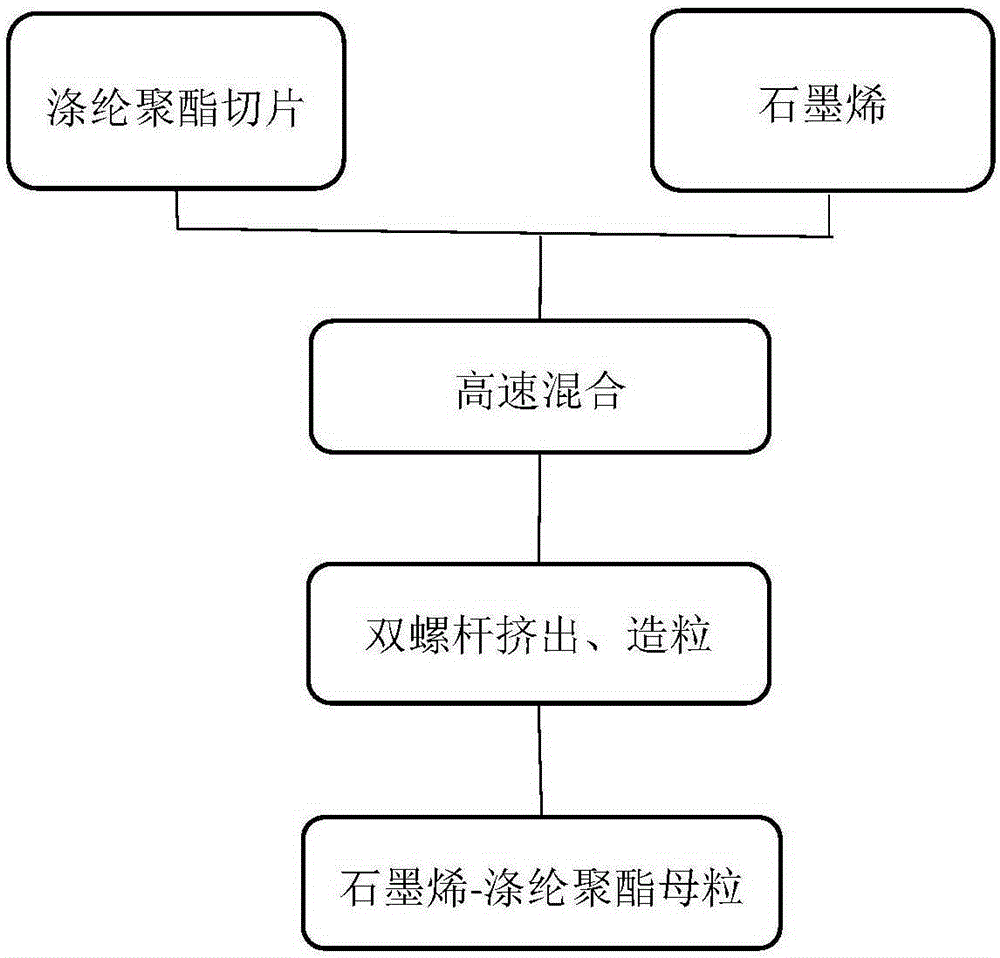

[0046] Step 1, the preparation steps of graphene-polyester polyester composite masterbatch (see figure 1 ) comprising: mixing polyester polyester chips with graphene (the mass ratio of the two is 100:0.1) at high speed, twin-screw extruding, and granulating to obtain:

[0047] Wherein, the type of the graphene is selected from graphene oxide exfoliated by chemical oxidation, and then organically modified and modified by hexadecane bromide;

[0048] The polyester polyester chip needs to be dried before use; the moisture content in the dried polyester polyester chip is below 50ppm;

[0049] In the implementation of the above steps, the polyester polyest...

Embodiment 2

[0056] This embodiment is a modification of Embodiment 1, and also provides a method for preparing graphene-polyester nanocomposite fibers, the only difference being that the type of graphene is selected from reduced graphene oxide that expands at low temperature.

Embodiment 3

[0058] This embodiment is a modification of Embodiment 1, and also provides a method for preparing graphene-polyester nanocomposite fibers. The only change is that the ratio of the mass of polyester polyester chips to graphene during the preparation of the composite masterbatch The ratio is 100:20; the high-speed mixing method is 25000 rpm stirring for 0.5 min. Then the composite masterbatch is mixed with pure polyester polyester chips and then spun, so that the content of graphene in the final graphene-polyester nanocomposite fiber is completely consistent with that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com