Method for plating chromium on surface of plastic material

A surface chrome plating and plastic technology, applied in the field of plastic surface chrome plating, to achieve the effect of suppressing volatilization, enhancing bonding force, and smoothing the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

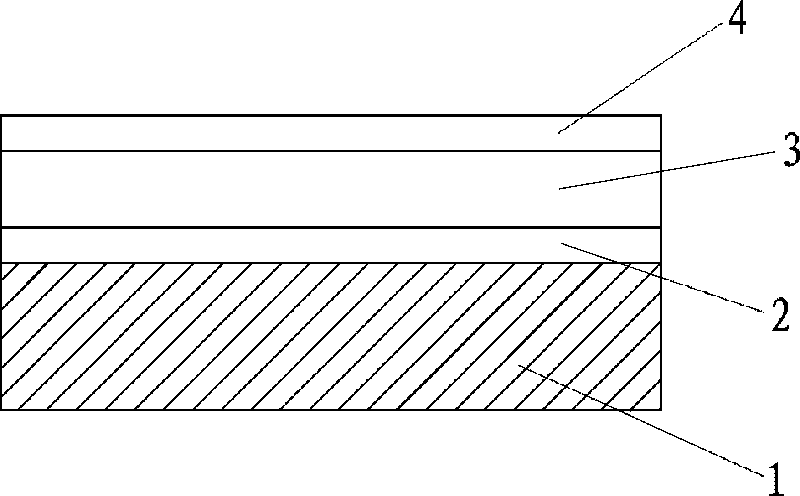

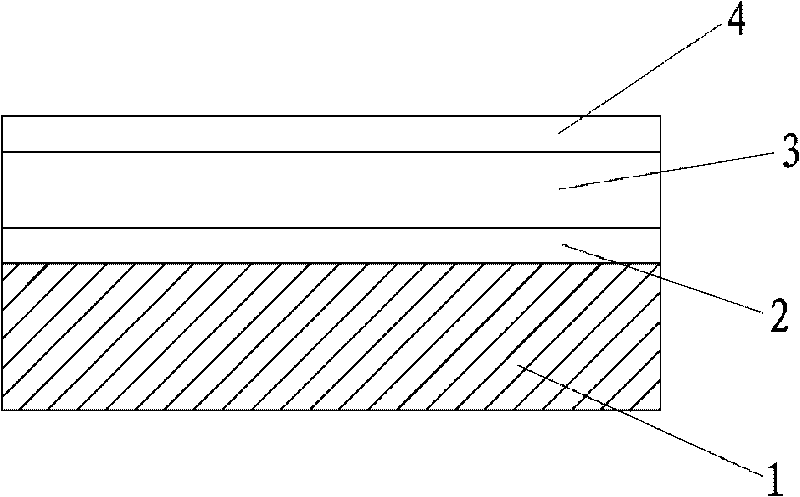

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

[0033] A method for chrome-plating a plastic surface, which comprises successively

[0034] 1. Preprocessing steps:

[0035] Remove oil stains, residual release agents, static electricity and dust on the surface of polycarbonate substrates; residues of release agents such as zinc hard acid and silicone oil are likely to cause defects such as poor adhesion of the bottom coating, so to remove them, use organic solvents Remove oil stains, and use an electrostatic precipitator to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com