A kind of ceramic tile with copper metal texture and preparation method thereof

A technology of ceramic tiles and copper metal, applied in the field of ceramic tiles, can solve the problems of weak decoration, dull color, single metal texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

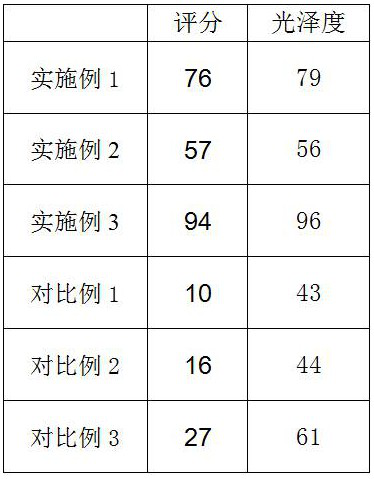

Examples

Embodiment 1

[0033] Ceramic tiles with copper metal texture, including:

[0034] Take 60 g of iron phosphate, 240 g of the hybrid, 0.0g of quartz 70g, sodium stallus, 20g of burna, 40g of alumina, borite 40g, high boron, 100 g of high boron

[0035] The above materials were mixed with ball mills to obtain a glaze, and the glaze was mashed to form a topping on the body;

[0036] The glazed glaze is applied to the top of the top, and the ceramic tile with copper metal texture is obtained.

[0037] The preparation method of aluminum phosphate aluminum phosphate includes:

[0038] Toint cyanuric acid 120g, melamine 120g, aluminum phosphate 120g, montmorillonite 240 g, silane 60g, ethanol 2000g;

[0039] Add melamine, aluminum, montmorillonite, and ethanol, mixed at 50 to 70 ° C for 10 min, and stir for 6 h;

[0040] Cyanuric acid was added at 60 ° C, and the reaction was 8h;

[0041] At 60 ° C, it was extruded into a silane reaction for 1 h;

[0042] Cooling, filtration, drying, pulverizing, and s...

Embodiment 2

[0049] Ceramic tiles with copper metal texture, including:

[0050] Take 60 g of phosphate, 250g of phosphate, quartz 70g, sodium, sodium, 20g of burna, 40g of alumina, 40g of flavous talones, zinc oxide, 100 g of high boron

[0051] The above materials were mixed with ball mills to obtain a glaze, and the glaze was mashed to form a topping on the body;

[0052] The glazed glaze is applied to the top of the top, and the ceramic tile with copper metal texture is obtained. The phosphate is commercially available in commercial phosphate, Hubei Hongjing Chemical Co., Ltd. CAS: 7784-22-7.

Embodiment 3

[0054] Ceramic tiles with copper metal texture, including:

[0055] Take 60 g of iron phosphate, 240 g of the hybrid, 0.0g of quartz 70g, sodium stallus, 20g of burna, 40g of alumina, borite 40g, high boron, 100 g of high boron

[0056] The above materials were mixed with ball mills to obtain a glaze, and the glaze was mashed to form a topping on the body;

[0057] The glazed glaze is applied to the top of the top, and the ceramic tile with copper metal texture is obtained.

[0058] The preparation method of aluminum phosphate aluminum phosphate includes:

[0059] Toint cyanuric acid 120g, melamine 120g, aluminum phosphate 120g, montmorillonite 240 g, silane 60g, ethanol 2000g;

[0060] Add melamine, aluminum, montmorillonite, and ethanol, mixed at 50 to 70 ° C for 10 min, and stir for 6 h;

[0061] Cyanuric acid was added at 60 ° C, and the reaction was 8h;

[0062] At 60 ° C, it was extruded into a silane reaction for 1 h;

[0063] Cooling, filtration, drying, pulverizing, and sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com