Radar stealth and infrared stealth integrated stealth tarpaulin and making method thereof

A radar stealth and infrared technology, applied in the field of wave absorbing materials, can solve the problems of complex preparation process, uneven surface density, falling off, etc., and achieve the effect of simple overall structure, high mechanical strength and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

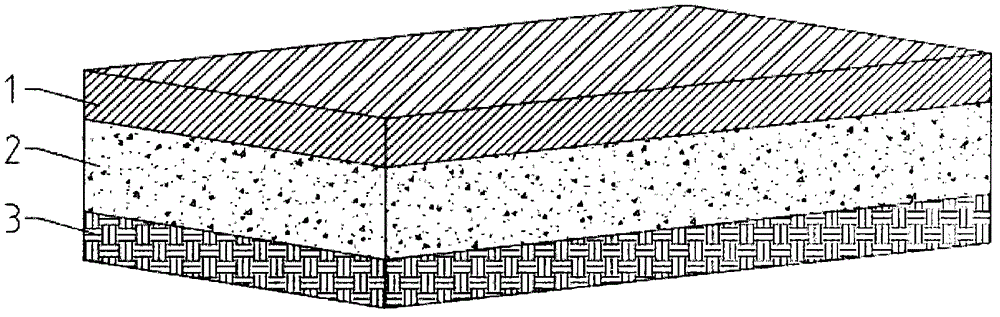

[0026] A radar infrared stealth integrated composite stealth tarpaulin comprises a camouflage layer (1), a radar infrared stealth layer (2) and a base layer (3) sequentially from outside to inside. The radar infrared stealth layer includes silicon carbide fiber cloth, polyaniline composite layer and infrared stealth coating, and its total thickness is 0.6mm. In the infrared stealth material, the film-forming material accounts for 30%, the reflective seasoning accounts for 60%, and the heat storage and heat preservation microcapsules account for 10%. According to the GJB 2038A-2011 radar absorbing material reflectivity test method, the radar infrared stealth integrated composite stealth tarpaulin prepared by this method is tested, and the results show that the reflectivity is above -8dB at 3.8~12.5GHz, and the maximum is -34.3dB .

[0027] Concrete preparation method comprises the following steps:

[0028] (1) Use the four-step three-dimensional weaving technology to weave si...

Embodiment 2

[0036] A radar infrared stealth integrated composite stealth tarpaulin comprises a camouflage layer (1), a radar infrared stealth layer (2) and a base layer (3) sequentially from outside to inside. The radar infrared stealth layer includes silicon carbide fiber cloth, polyaniline composite layer and infrared stealth coating, and the thickness of the radar infrared stealth layer is 1.0mm. In the infrared stealth material, film-forming substances account for 40%, reflective seasonings account for 45%, and heat-storing and heat-preserving microcapsules account for 15%. The camouflage layer includes a waterproof breathable film and a camouflage stealth coating, and the base layer is a matt high-density polyester fiber cloth. According to the GJB 2038A-2011 radar absorbing material reflectivity test method, the radar infrared stealth integrated composite stealth tarpaulin prepared by this method is tested. The results show that the reflectivity is above -8dB in 4.0~12.3GHz, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Reflectivity | aaaaa | aaaaa |

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com